Page 1 of 1

Little Hickman Sea Sled

Posted: Fri Nov 30, 2007 2:27 am

by Fred in Wisc

Well I've had the TX18 plans for quite a while, so it's time to finally start building something.

Project considerations were: Provides a stable fishing platform for max 2 adults and a young 'un. Can power with oars, electric, and little outboard. Fits in the back of my minivan for short trips to the lake. Light enough to load by myself. Gotta fit up the basement stairs 'cuz it's real cold (11 degrees this morning) in the garage.

I live right outside Milwaukee WI. Since it's quite populated, many of the lakes in our area have limited public access (10-20' wide strips of grass for carrying canoes, or access down small shallow rivers). Seems the "fancy people" with waterfront property are sometimes a bit posessive of "their" lake.

Anyway, I have been lurking around here for years, built a S&G canoe a couple winters ago but wanted something more substantial. (Fishing in a canoe with kids.....bad idea. Dogs are even worse....No offense to Captain Sam.)

Thought about a little plastic "bass tender" but only for a minute. Considered the FL12, V12 and some others. But the TX18 is just SO COOL that I figured I'd scale it down and build that. (I'm a sucker for cool looking stuff, shiny things, and things that make loud noises. If I was a fish I'd never have a chance...) Got the plans. The SS18 Sea Sled plans were included. I decided to build that at 55% size and raise the freeboard a couple inches in the rear, creating a pretty much level sheer line. I would have liked to do 65%, but I'd need a wider minivan and some time at the gym to lift it.

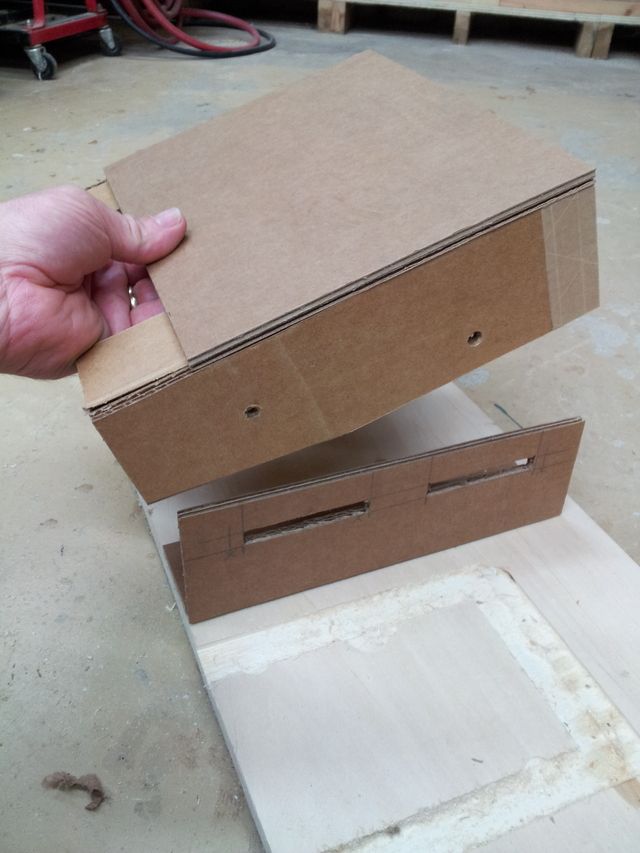

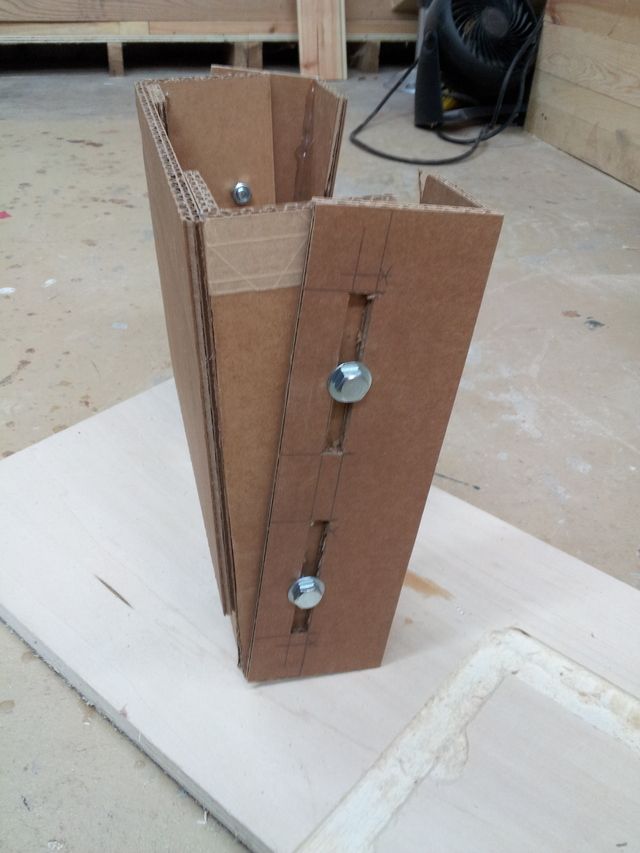

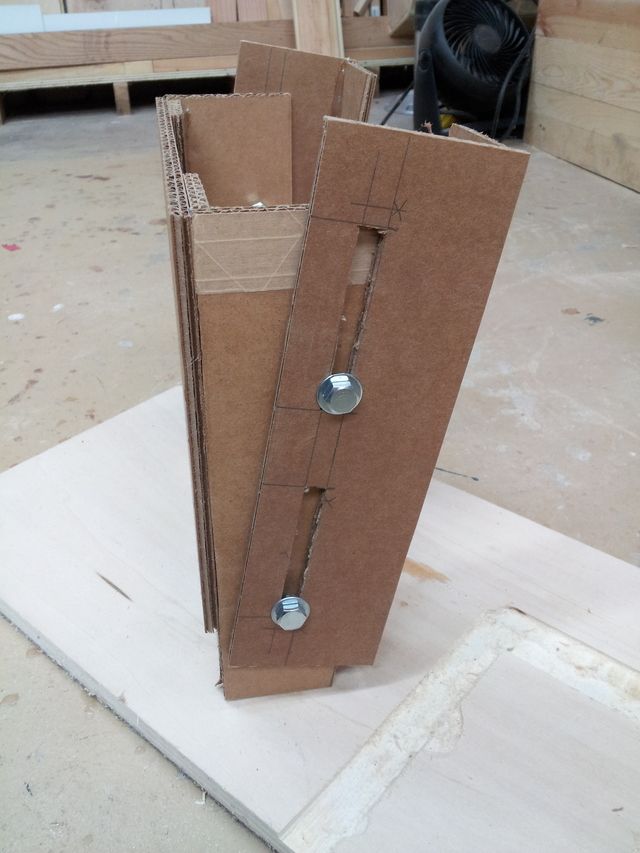

Spent a couple hours messing with the plans and the math to get it so it looks about right, then created the stringer and panel dimensions. Raised the sole 3/4" to get more substantial stringers and frames under the floor.

Using 6mm okume for frames, 4mm for hull, double 6mm for stringers.

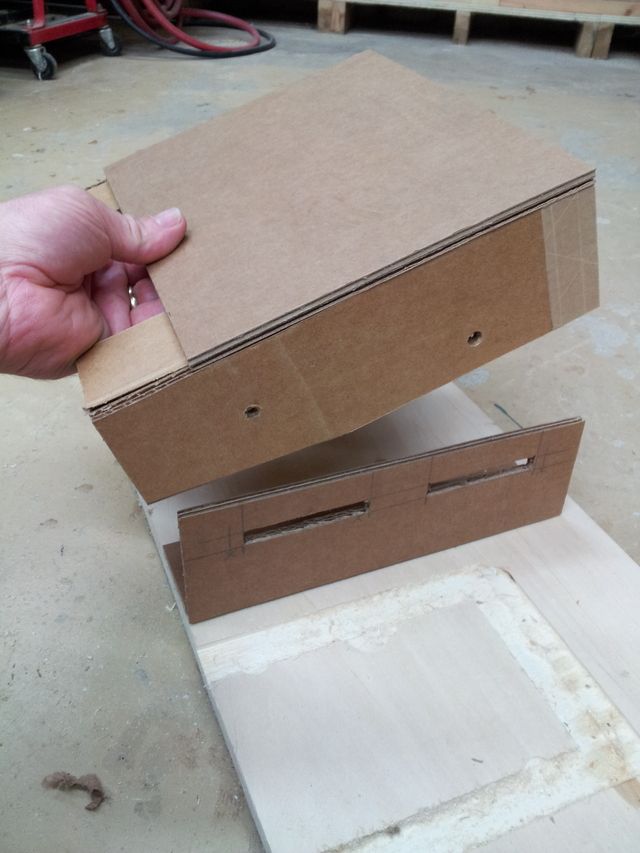

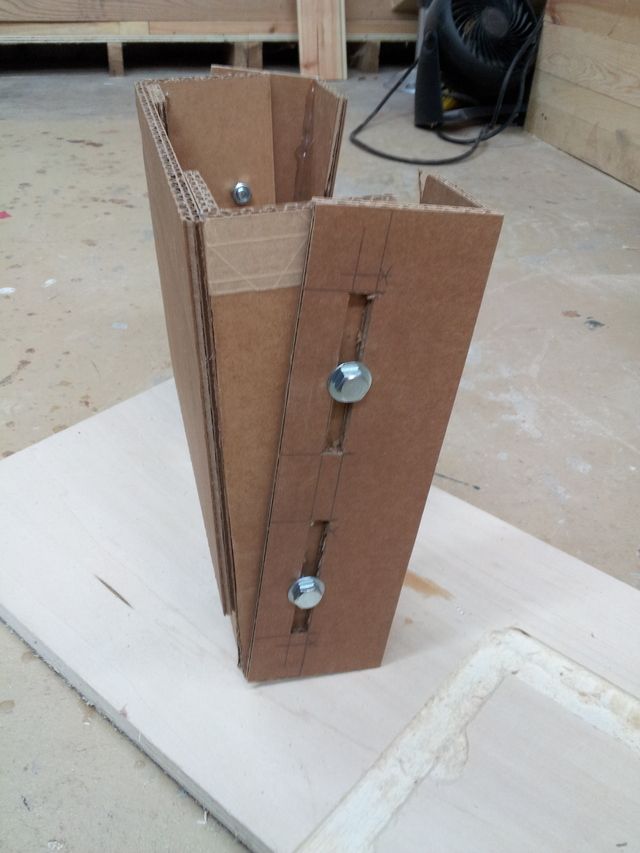

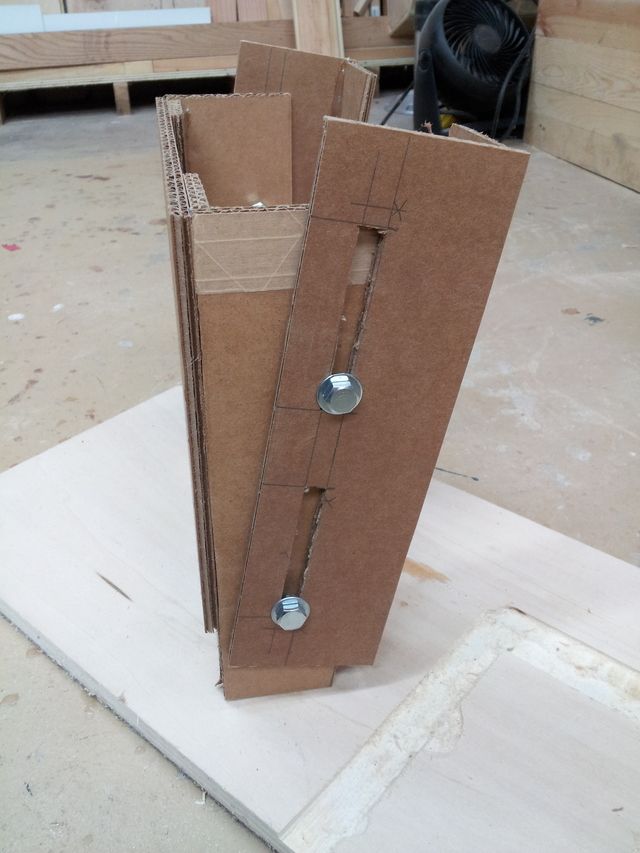

Since the boat is so small, I decided to build the frames as single pieces (in the plans they are each 4 parts assembled around the stringers). Worked out the nesting to get all the frames out of one sheet of 6mm. That was sweet. Had about 1/4 sheet left over.

Laminated 2 layers 6mm to form the stringers. Offset the joints about 7 feet. The stringers are only about 9 feet long.

Then I set up notches in the frames and stringers so the whole thing could be assembled and glued up. Covered my cast iron tablesaw in plastic, used that as a flat surface for assembly, squared everything up and started mixing epoxy and woodflour. It was way easier than I expected. And after setting up, it's almost perfectly square and level. Pleasant surprise. The sheer line is close, but will end up needing a little adjusting to get it just right.

The fillets are not pretty, they will need some sanding before taping to the hull, but hey, they're under the sole so who's gonna know? Just me and I won't tell.

Here's a few pics of the progress so far. Let me know if they don't show up, I haven't posted any before.

By the way, I would still be slacking on this except for seeing the pics of Daniel Huckleberry's boat. Thanks for the inspiration, Daniel. That's a beautiful boat.

I'll post more as it comes together.

Fred in Wisc

[/img]

Posted: Fri Nov 30, 2007 8:47 am

by davidtx

This looks very cool! So if I did my math right, it ends p about 9'10" by 4'5". It doesn't look like you are very concerned with speed given your list of propulsion requirements, but I wonder how much motor it would take to make this plane. This looks like fun, please keep posting.

Posted: Fri Nov 30, 2007 10:43 am

by Dougster

Boy that's neat looking. Please keep posting as it goes along. I'm curious too what you'll power it with. Re rough fillets under the sole, well, heck, who cares? Seems like a creative, fun project.

Got the day off and gonna smear some 'poxy Dougster

Posted: Fri Nov 30, 2007 12:03 pm

by Fred in Wisc

Thanks for the kind words gentlemen. Speed isn't too important, I usually fish small lakes ("tanks" to you Texas fellas if I recall) and a little rowing is a good workout. For bigger water, I'm planning to power it with my Johnson 8hp 2 stroke. That little motor planes my dad's 14 foot aluminum with 2 guys so I'm guessing it should be plenty. It's nice and light too.

With the extra sheer, it's a little longer, may turn out near 11 feet depending on how I do the front deck lip. Just about 4 feet wide, the SS is a little narrower than the TX.

Anyway this boat should be good practice for building the full size one some day. That's a big project though. Need some extra shop space at work to do that one.

Here's a question for anybody out there: I find 3 and 6 gallon gas tanks everywhere. Really I'd like about a 1 gallon tank to save space and weight. Does anybody know where to get one or will I need to get creative?

Also for all the guys who use Dremel tools for smoothing out fillets and such, I found a great deal on the little samding drums and mandrels at Widgetsupply.com. 100 1/2" sanding drums with a pair of mandrels for 10 bucks.

Fred in Wisc

Posted: Fri Nov 30, 2007 3:43 pm

by Daniel Huckleberry

Cool idea, Fred! Thanks for the compliments on mine. I can't see the pic, but that happens to me alot at work (server blocks them). I will look when I get home. I would love to scale the SS18 up, but more than 10% and I am sure JM wouldn't like that much.

I think that will make a super cool little lake fishin machine.

Keep us posted!

Huck

Posted: Fri Nov 30, 2007 3:58 pm

by AdamG

looks cool! I like it. I'd have cut the sides down, and made it into more of a powersled myself, just to reduce weight, as I wouldn't probably be using it where large waves are an issue. but to each his own.

Question now is does this "mini" version use up your "license" for the TX18, and you will have to buy another set of plans for the full size? Doh!

Posted: Fri Nov 30, 2007 4:16 pm

by sds

Looks good so far!

One issue: the pictures are kinda big at 1,024x768 -- I have to scroll right and left to see them, and to read the text. Alot of other readers are probably in the same boat.

Suggest resizing photos to a max 600 pixel width -- you can probably do this right on photobucket.

Anyway, cool project. Looking forward to see how it develops.

cheers,

Scott

Posted: Fri Nov 30, 2007 10:36 pm

by Fred in Wisc

I guess the little guy will use up my license, but I don't mind paying for another. If I do a TX18 eventually, that should be about the smallest expense involved. I'll bargain hard with the outboard dealers to make it up.

About the pics: They show up fine on my 'puter, just a little short of full screen width. I have to scroll over oa touch to see the last bit of text, but that occurs on many of the forums here for me so I thought it was normal. How are others seeing this? Please leave some comments so I know. I can scale the pics down easy enough. Just want to make it easy to use for everybody.

Trimmed up a couple panels today and got the tunnel panels zip tied down. Gotta tinker with them some to make it all fit up nice, so that may be a few days. This may take a bunch of ties to get it all fittin' happy at the bow, lots of stuff coming together there. Doesn't fit quite as well as I'd like in a few areas, but that's what I get for messing around with Jacques' design.

Fred in Wisc

Posted: Sat Dec 01, 2007 3:38 am

by steve292

I resize mine to 600 x 1200, which I find fine. I have to scroll sideways a bit to see all of yours.Nice work on your framing, interesting thing to do, scale down the TX18. It will be good to watch I think.

Steve

Posted: Sat Dec 01, 2007 4:07 pm

by ross61

Hey Fred,

Where are you located? I am in South Milwaukee. Built an FL14 about 4 yrs ago and I still have it. It has held up great. Let me know where you are and maybe I can bring over a sander and give you a hand when you get to the fairing stage. Interesting project. I really admire all the ingenuity of builders on this forum.

I'm typing this from the Dells where we are suffering an ice rain/sleet/snow combination. Oh well, nothing wrong with sitting in front of the fire with a cocktail.

See Ya!!

Ross

Posted: Sat Dec 01, 2007 9:02 pm

by Fred in Wisc

Next pics I'll scale 'em down.

Ross, I live in Hales Corners and work in Waukesha. Wouldn't mind some help with the sanding when I get that far.

It's nasty out here too. Got about 5" of snow mixed with freezing rain sitting in the driveway waiting for me.

Fred in Wisc

Posted: Thu Dec 06, 2007 11:41 am

by SalmonMan

Hey Fred,

Nice work you are doing! Are you building a Texas Sled hull or a Sea Sled hull? The reason I'm asking is because from the study plans I thought that the Sea Sled hull had an inverted vee on the bottom at the transom.

Keep up the good work! It looks great!

Posted: Thu Dec 06, 2007 4:06 pm

by AdamG

Looking at the frames on the second pic, and the way they come up a little along the keel line, I'd say it is the seasled version.

Posted: Thu Dec 06, 2007 9:18 pm

by Fred in Wisc

It's the Sea Sled. The inverted V at the back is only a coule of degrees, I think it came out to 3/8" or so at the center.

You can just barely see it in the pic.

I should have pics of the hull plywood zip tied out soon, I've been playing with getting it fair and the gaps pretty uniform. Found a math/cutting error, but nothing I can't fix with a scrap of ply and some epoxy.

Fred in Wisc

RE Sea sled

Posted: Thu Dec 06, 2007 9:36 pm

by Mike Redmond

HI,nice work keep up with the pics...Did you figure out how much it will weigh ,the weight of a boat is a constant preocupation with me ...getting older not stronger...11 you lucky little d...il minus 23C yesterday morning in Edmonton Brrrrrrr winter is not officially started and I cant hardly wait for spring to show up...So have a nice build you seam to have a good start on the project Mike R

Posted: Sat Dec 08, 2007 8:23 am

by Daniel Huckleberry

Fred, I checked your pics at home! They look really good and bring back great memories! I am itching for another build to start already. Scaling that Sea Sled might just be the ticket. I have several offers on the TX sled already! I won't be without a bateau again, though. I love these designs. Next one will have to be finished before I let her go.

Best of luck and keep posting pics!

Huck

Posted: Sat Dec 08, 2007 10:50 pm

by Fred in Wisc

Again, thank you for the kind words. Especially Huck, that means a lot coming from you, your workmanship is excellent.

Mike, I see that you need a boat you can fit out out of the basement. I'm in exactly the same situation. This will just barely make it up the stairs, at least in my house. I suppose all you Canadians have metric stairwells. Sorry couldn't resist.

If you are interested in the little sled, I'll be glad to share my dimensions and sketches. The TX plans from JM are superbly detailed, but he included the Sea Sled plans with less detail (just as stated in the plan description) so there was more to figure out. You'll still need to buy the TX plans of course, but I'll be glad to share the extra stuff I developed with anyone here.

The weight, I'm not really sure yet, I always end up heavier than I plan to. The skeleton is really light, maybe 20 pounds or so for all the stringers and frames. The rest is about 2 sheets of 6mm, 2 sheets of 4mm, and 2/3 sheet of 12mm for the transom. Probably 4 gallons of epoxy if I can control myself there. Then some foam, but that's light.

I'm guessing it will be kinda hard to load alone, but not too bad with my 9 year old neighbor kid helping.

Fred in Wisc

Posted: Sun Dec 09, 2007 7:45 am

by Daniel Huckleberry

Hey Fred, Thanks. But I can tell you that my pics look a little better than in person. I got real tired of sanding! Decided it was good 'nuff! Now that it's got river mud, salt and little bits of grass on it, you can't tell at all!

Good luck and great building. I gotta check this at home again to see your new pics.

Huck

Posted: Wed Dec 12, 2007 1:08 pm

by Fred in Wisc

Finally had a bit of time to work on the boat. It got cold out so we have been buried in remote start installations at work. Well can't complain, it pays the bills.

Anyway, I got the bottom panels and chines cut out and am working on getting them lined up before tacking them together. Gotta do a couple fiberglass splices in the sides panels and they will be redy to go too. You can see where I had a couple of calculation / layout/ cutting errors. The bow was not extended far enough when I raised the sheer, had to glass on a coule more inches of ply. And when I seamed the bottom panels together, for some reason the ends of my ply were not square so I ended up with a gap in the center. I think my miter gauge on the table saw was not right at 90 degrees. It's not a catastrophe, I'll just put that little traingel shaped filler in at the stern. There are a lot of layers of tape over it by the end of the build, so it will be plenty strong.

This is just layed on top, loosely fastened, I don't want to do the final zip tying until I have all the panels and have the table leveled carefully so I can check everything for level and square assembly.

I also was having trouble seeing how I could maintain gaps between the frames and ply, since there are some fairily complex angles and bends in the boat. I came up with the solution of gluing little bits of dowels to the frames to maintain gaps. I used just a tiny dot of superglue on each, so they will snap off with a good tap, then the glue can be sanded off with just a couple strokes with the sandpaper. I zipped a few panels down to test it and it works real well.

Also tried to use the little pieces of pvc pipe trick to get the center seam to line up nice, but it kept pulling the gap shut, so I made these to maintain the gaps and panel alignment. Works pretty slick.

Once I get the panels all zipped down and aligned nice, I will post more pics. That process is kind of trying my (admittedly limited) patience, but I know it will be way more work later to fix anything that's not laid out correctly now.

Fred in Wisc

Posted: Wed Dec 12, 2007 1:51 pm

by jacquesmm

There is something wrong with the bottom panels.

Are those our panels but scaled down?

If you did not make any other changes, they should fit.

Did you try to flip them? I mean turn them over, try the other edge for the center keel.

Don't worry about the gaps, keep it simple.

Posted: Wed Dec 12, 2007 5:15 pm

by Fred in Wisc

Yeah, there is something wrong, but it's my fault. When I glued up the splices in the bottom panels, I did not notice that theplywood was not cut quite square. They were actually angled out a bit. So they ended up not fitting at the transom.

It wasn't a big enough error that I felt compelled to redo the panels. I just cut a little filler piece and went with it.

Should I redo the panels? It did not seem like that little change at the end of the inverted V would make a difference, but if you think it will, I'll do 'em over.

Or I could splice in a piece on each side to maintain the sharp meeting point at the inverted V. Actually, I think that's what I'll do, it's no more work than the one filler piece. I'll post pics when it's fixed.

Fred in Wisc

Posted: Wed Dec 12, 2007 9:20 pm

by jbo_c

Can't wait to see this finished out. Looks like it will make a nice little boat for protected waters.

Jbo

Posted: Fri Apr 25, 2008 8:46 pm

by sraab928

Any updates Fred? Im really curious to see how she comes out.

Posted: Mon Apr 28, 2008 1:06 am

by Fred in Wisc

Thanks for checking in on it. I have been making some progress, but just a little at a time. Business has been good so I'm at the store a lot and I have a toddler, which really limits my late night power tool use (momma would kill me if I wake baby).

Since I need to do some sanding before the next step, I've been at a standstill for a while. Tried hand sanding, but that is surprisingly loud on a thin plywood hull. Plus power tools are way more fun.

Got a 7" random orbital, I think it was Dougster that suggested that. It's really fast and my new favorite sander. Gotta run it on low speed and watch out, though. I nearly cut throught the 4mm ply in one spot with it. Nothin' a little wood flour putty and an extra piece of biax tape didn't fix....

I actually have the hull assembled, taped on the outside, filleted, taped, and biaxed on the inside.

I found that I had 2 math errors in scaling. Both resulted in the ends of the panels not quite touching at the centerline of the boat. Grrr.... Anyway, I just had to splice in some narrow little triangles, do a little sanding, and all is well again. Guys, if you are scaling anything, double check your math when you calculate and when you measure. I spent several frustrating hours trying to bend this into shape before I realized what I had done. And it was no fun at all.

It's flipped upright now so it looks like a boat. Flipping was super easy with 2 guys, the hull weighs probably 40 or 50 pounds.

I extended the sheer up higher, the sheer line is real ugly right now. Gonna cut it down to a pleasing shape once I get the frame / stringer assembly installed.

I'll see if I can get some pics up in the next couple days.

I did find that the biax cloth is wonderful around curvy hull sections, but wow does it eat up the epoxy. Seems like it uses way more than the woven did on my last project. I'll have to order up another batch soon.

Fred in Wisc

Posted: Mon Apr 28, 2008 5:57 am

by sraab928

Thanks for that update Fred - I cant wait to see the pics. Hey business being good is a good thing and I totally get the not waking the sleeping baby angle. We pray for those peaceful moments...lol.

Thanks again and get some pics up! Im salivating here.

Posted: Mon Apr 28, 2008 9:36 pm

by Fred in Wisc

As promised, new pics. It looks like a boat now. That part is exciting.

Here you can see the inside is glassed with 12oz biax. I had a little but not much excess resin pool up in the low spots. I did the tape and biax wet on wet, but ran out of time to do the sides in 6oz woven. Gotta sand and come back to them.

Figured some light woven cloth o the upper hull panels wpould be good, I am kind of hard on boats and the hull is only 4mm okume.

Here you can see the notches in the transom into which the stringers will fit. Need to dremel them out first.

the transom is 6mm okume backed with 1 layer 12mm Baltic Birch and then 2 more layers Baltic Birch as a claming board up top. The birch was obtained locally and has a few voids. those will be epoxy filled with a glue syringe. It should be plenty strong for the 8hp 2 stroke Johnson outboard that will power this boat.

If you look carefully you can see where I sanded almost through the ply and had to fill it in. You can also see where I had to splice in 2 thin triangles to get the bow to meet up correctly. That was a layout error on my part. Be really careful when you are scaling stuff. It would be way easier to buy a plan that is the size you want. I just never seem to do things the easy way.....

This one you can see how nasty the sheer looks prior to being trimmed. That will be elegant and pretty later on, don't judge now. I was not quite sure how high I would need it, so I made it pretty high. Figured it would be way easier to trim it off than to add it on.

I'm booked solid at work until May 15th or so and then going on a little cruise with the family, so not likely to make much progress until the end of May. Plus it's finally getting warm enough to go fishing here and the neighbor kids are starting to ask me about catching some bluegills.

As a wise man once said "Build on Dudes"!

Fred in Wisc

Posted: Tue Apr 29, 2008 8:31 am

by sraab928

Fred - that looks great! Thanks for sharing! That is going to be one custom little sled!

Posted: Sat May 24, 2008 11:49 pm

by Fred in Wisc

Finally got some time to work on the boat again. Got back from vacation yesterday, my wife and daughters stayed to visit Disney and hang out a the beach a bit.

Hadn't been to Baja Cali before. It's beautiful, love the area around Ensenada. And I got the best tamales I have had in a long time from a roadside stand for a buck. I'd like to head back for a while, spend some time fishing. My cousin Andy caught a real nice marlin at Cabo a couple years ago, so he's ahead of me there. I've only hooked one once, a white marlin off Cancun, lost after a brief fight. Ran towards me and I just couldn't get the slack out of the line.

How can you guys out there stand the sea lions? The ORK-ORK-ORK sound they make is cute for about 15 minutes, then it's maddening. It's like having 800 pound seagulls hanging out at the dock or something.....

Anyway, on the topic of boat building.

Spent a couple hours sanding last night. Got a big cheap 7" sander at Harbor Freight that makes it go real fast. Need to set it on the lowest speed and be careful, though, it removes a lot of material fast. I dremeled the stringer notches out of the transom and chiseled out the epoxy that soaked into them. Set the stringer/frame assembly in place, marked the areas I need to sand to tape the stringers down. Why sand it all if it's not needed?

I remember now why sanding sucks. Messy and itchy. Thinking about a HEPA filter for my Ridgid vac. Has anyone tried them? I hate to spend $30-40 on a shop vac filter without some preliminary information.

Got most of the bottom and one side sanded. Hoping to finish the sanding tomorrow between church and picking up my family at the airport. I can epoxy anytime, it's quiet. traying to get the loud parts done before they get home.

I'll have to get the little RO sander out to do some of the details and areas where the panels meet, the 7" is too hard to control and tends to cut through the glass with the edge of the disc if you touch the next panel over.

Then I'll need to modify the front of the stringers a little, they are hitting the inside curve of the hull and making the shole stringer assembly ride up so the space between it and the hull is about 1/8" at the back increasing to about 5/8 at the front. I don't want to use that much putty so I'll get the plane out and shave down the front 12" or so of the stringers a bit.

I'll post pics when there is something interestng to see.

Fred in Wisc

Posted: Tue May 27, 2008 10:36 pm

by Fred in Wisc

Well, here are the pics of the last few days' progress on the boat.

I sanded down the whole interior with 80 grit on the 7" sander. Did some detail areas where it did not fit with the 5" and 60 grit (it's faster, I'm not very patient with sanding. Swept and vacuumed it out.

Sanded all the old epoxy drips and smears off the frame and stringer assembly, it's been months since that went together so I'd rather bond to fresh wood than old epoxy. Also sanded down all the fillets, they were not real smooth and would have either used a ton of putty to cover or given me bumpy tape seams. That seems like it would give you all kinds of stress risers so I want it smooth. Trimmed the aft ends of the stringers about 1/8" to get a gap for epoxy behind them. Sanding this only took about 20 minutes with the big orbital.

Then I built a strongback of sorts to hold the boat level so it gets assembled straight. I set it up so the stringers and frames are level front to rear and side to side. This will greatly simplify getting the rest of the assembly straight.

Then I fit up the frame and stringer assembly to the hull, making the gaps between the hull and supporting members as even as possible. This took some time and patience. Lots of planing and sanding. The strong curve near the bow required a lot of work the rest was pretty good, just a little trim way in back where multiple layers of 12oz on the hull made the gap too big. After this, the front to rear adjustment on the strongback needed a little fine tuning. Now I'm quite happy with it, very close to actually being level.

Here you can see that the gap between the frames and hull is prettty even on the sides. I had to plane down the frame nearest the transom just slightly to get this right. The aft gaps are a bit bigger than those farther forward, but putting a little weight on the bow makes it flex just a touch and adjusts that nicely. When I get to that part, I'll weight it down a bit and then glue it.

I pulled the frame back out and coated the bottom edges in epoxy (wow I am excited to be using that stuff again.) Put it back in the hull and set up a couple spacers to avoid hard spots.

Taped in the first couple sections. Precoat, fillets, then 12oz wet on wet. I figured on using 12oz right near the transom and then 6 oz for the remainder of the boat. That should be plent strong for the lightweight materials here. I figure if I do a couple sections every 2-3 days I will still get chemical bonding, so that's the plan.

I'm using way too much epoxy with the brush. Next work session, I'll get the roller out and wet out the tape on the bench. That should save a lot of resin. Ordered another batch today, along with wood flour and quickfair.

Even a cursory examination of the taped seams will reveal I am no Cracker Larry or ks8. Don't laugh, you probably aren't either. Once the sole is down nobody will ever know.

A ballpark calculation says I can get about 6-8 cubic feet of foam under the sole. Approx 7 feet x 3 feet x 3 1/2 inches. That should supply plenty of buoyancy in case of emergency. Plus I'll stick a little more up in the bow once I work out how the front deck is being configured.

There will be some 6oz woven on the hull sides , it will slip right in between the hull and frames and the whole sheathing, fillet, tape deal will go in wet on wet. That's the plan at least. I don't see why it won't work. Certainly possible that a reason will be revealed later, but I hope not.

Gotta go, I have a pizza ready, the family should be home any time.

Fred in Wisc

Posted: Wed May 28, 2008 1:04 am

by ks8

I really want to see this little giant on the water! Taking shape nicely...

Only one problem with this gem of a scale down. Someone will want to build one, deck it over, and cross the Atlantic... with solar electric... or pedal power...

Posted: Wed May 28, 2008 11:26 am

by SalmonMan

Hey Fred,

Your boat is coming along nicely! You're doing a fine job on it. How deep is your boat? I'm talking about the distance from the top of the stringers (or sole) to the top of the gunwales. It looks like about 20 to 24 inches to me.

Keep up the great work you doing on the boat!

Posted: Wed May 28, 2008 12:24 pm

by Fred in Wisc

It looks really deep but the whole thing is really quite small, since it's only 10' long and just under 4' wide.

The depth from the top of the stringers is 13 to 16 inches depending upon where you measure. That maygo down a little when I trim the sheer, but only an inch max. I'll just be trimming off the stuff that looks too high.

The depth of the stringers is 4 9/16, plus gaps and the hull bottom, so the transom at the center is about 19" high on the outside. Had to raise it a little to accomodate my 20" shaft motor.

Thanks for checking it out.

Fred in Wisc

Posted: Fri May 30, 2008 1:12 pm

by Fred in Wisc

Got a little more done this morning. Filleted and taped several more compartments until I ran low on wood flour. Ordered some on Tuesday so it may arrive today, otherwise Monday. A lot of my gaps are around 3/8 on and it really uses a lot of wood flour to fill them in. I'm making the fillets small, but the gaps really eat a lot of putty.

Used a little roller to wet out the cloth today, much faster than the brush, and it uses less epoxy. Then I go back with the brush to make sure all the corners are wet out completely and stuck to the fillets. If you have not tried rolling resin, you need to. I got 5 compartments done today in about the same time as doing 2 with the brush a few days ago.

Precoated the sides where the 6oz cloth will be installed, I have materials for that, so it may turn into this evening's project. I could get a layer of biax on the inside of the transom also.

Took some pics but they turned out really poorly. Sorry. Not much new to see, just another 25 or so feet of fillet and tape.

Seeking some opinions on interior layout. I've been pondering this a lot, but I may well have missed something. 2 basic options:

1. Flat sole as far up as I can get it (about 6 1/2 feet from transom). Minimal furniture, maybe a couple of removable pedastal seats with extra bases so I can accomodate different numbers of anglers. (Sometimes fish alone, sometimes with one or 2 others- max load 2 adults and a kid.) I like the light weight and simplicity of this option.

2. Mini bass boat setup with front and rear casting decks. Probably not raised all the way to the sheer, might be tippy, and I like a little ledge when I'm fishing with kids. Set up the rear deck like the SC16 where it also functions as the rear seat. I like the storage space (nets, tackle, PFDs and such can tuck under the decks out of the way but in easy reach) and the better position for sight fishing with this option.

Either way, I will probably set up a front clamping board for a bow mount troller (hand controls) with a real small battery. ( I have a 20 amp-hour gel cel that weighs about 15 pounds, perfect for a short trip in a little boat.)On my little Minn Kota motor, you can just take out one bolt that holds the control head to the shaft, turn the head around, and put the bolt back in. Instant bow mount.

Any input on advantages/ disadvantages? Thanks.

Fred in Wisc

Posted: Sat May 31, 2008 11:34 pm

by Fred in Wisc

Made somemore progress after work today. Got the inside top panels glassed with light woven fabric. Turns out I had 4oz, not 6, but it worked out just fine. Very easy to set out after working with all the 12oz biax. Running the cloth between the hull and frames was pretty easy. I just lightly sanded the cured precoated hull to get rid of points where the cloth would catch and fed it in at each frame.

I was able to bend each frame far enough fore and aft to roll epoxy underneath the frames.

It also finished out with a really nice smooth surface that should require very little filling and fairing to make it look nice. The Okume looks so good under that light cloth that I would consider bright finishing just for fun if I didn't need to tape in all those frames.

Also found some coast guard foam left over from my last boat, so I poured one compartment of that. Mostly just because it's fun watchin' it rise like some nuclear mutant bread dough.

I wish I was a better planner, almost out of 6oz biax tape and need more foam. Gotta order again next week. Should have got it all at once.

I see a few folks are following this thread, any input on the interior layout gentlemen? I'm going to be at that point pretty soon.

Sorry no pics tonight, I'll probably have a chance to do that tomorrow.

Fred in Wisc

Posted: Tue Jun 03, 2008 1:18 am

by Fred in Wisc

The DHL van brought me some more wood flour and epoxy today. Yee ha!

Finished filleting and taping in the stringers and frames up to the chines. doing the pointy ends at the bow took a lot of patience and wood flour putty. Then several small (6x6) pieces of biax over the tips to make sure they will stay put. Seems like an area that will take a lot of stress if (well probably when) I hit something at speed or beach the boat under power. Access here was difficult, had to use the paintbrush to apply resin. The stringers end in some very sharp V shaped portions of the hull., especially on the outside edge of the stringer. The chine panel is nearly vertical there and only and inch or so from the stringer. It was hard to reach the sides of the stringers. Hard to see them even. Ended up using too much resin to make sure everything was well bonded. I'll take an extra 4 oz of weight to make sure my stringers are bonded to the hull well.

I'm debating whether to just fillet and tape the frames up to the sole or all the way up. I'd like to do it all in one shot wet on wet, but I don't think I can get the rear deck in if the frames are taped all the way up. I'm going to do the casting decks front and rear. The problem is the transom is 3/4, but the clamping board on top of it is 1 3/4", so there is an overhang of about an inch I'll need to tuck the rer deck under. The frames easily flex 1", so it would be easy to insert the deck with them loose. Access to the underdeck will not be very fun since the deck is only about 10" off the sole. Good thing those stringers will be hidden below, I can't see that being my neatest work in such a small space. Probably the best bet is to leave the aft 2 or 3 frames loose, and tape the rest all the way up. This should stiffen the boat up a lot, give me easy access for nice neat fillets, and let me put most of them in wet on wet.

For the casting decks I am going to laminate up some balsa core panels. The only 3/8 or 1/2 marine ply I can find locally is fir, which is really heavy. I just can't justify shipping one piece of okume 3/8. The initial plan did not include casting decks, so I didn't order enough plywood. Anyway, 3/8" balsa core comes in 24x48 sheets and one of our regular shop suppliers has it not too far away, so that's the winner. I'm thinking laminating that with 12oz biax both sides should be strong enough. I'll probably put a small vertical beam at the edge of each deck to reduce flex. Then I'll make sure the edges are well sealed and protected to prevent water intrusion. I got 4 sheets, enough for 2 casting decks 30 to 36 inches long and about 40-44 wide, plus one for cutting errors. PS- compared to okume 1088, balsa core is really expensive- about $100 before shipping for the equivalent of a 4x8 sheet. I'll report back on how that works.

For the sole I am using 6mm okume 1088 with 9 oz glass on each side. The frames and stringers cut the floor into sections about 24x16 or so. It sound like most boats use about 1/2" with 6 or 9oz on the top only, but I'm doing top and bottom since the 6mm is pretty thin. Also a little paranoia, my aluminum boat floor was coated on top and rotted out from the bottom. I feel better knowing it's got fabric on , not just resin. Then I know I have not missed a spot.

Sorry for all the words and no pics today again. The camera is being freaky. takes pics with big pink/ red smears appearing randomly acroll the picture. I have another at work, so I'll get some pics up pretty soon.

Fred in Wisc

Posted: Tue Jun 03, 2008 11:16 pm

by Fred in Wisc

Got some pics guys.

Here is a stringer point glassed in. I wrapped the tape up around the top of the stringer, you can see where there is a little air gap under some of it. I'll have to drill a little hole there and inject some epoxy with a syringe. On both sides, unfortunately. I even covered these with plastic and put some small lead weights on them to try keeping the fabric pushed down but it didn't work so well. A little vacuum bag setup would have been so slick for doing this. Or even pouring a bag of lead shot over the plastic covered lamination. Unfortunately I was not prepared for either, so this is what I have to work with.

Here is a shot of the whole assembly, stringers and bottom frames all taped in. The front one is not done yet, the plywood is slightly warped and I am pondering how to best clamp it straight before making it permanent.

You can see the one compartment where I poured some flotation foam. Found it in the shop and could not resist playing with it a bit.

You can just see the board and storage bin on the bow. The hull sides are bowed out just a touch and putting a little weight on the bow (only about 30 pounds) draws them in nicely closer to the stringers. And the sides stay very fair this way, so I think it's better than just pulling the sides in towards each stringer. I could see getting wavy hull sides from that, and a lot more fairing.

Figured this is the best time to adjust transom height if I need to so I clamped the motor on the back. I can also use this to determine how long to make the rear deck so I have room to sit and steer.

It looks to me like the transom is about an inch too high. I am thinking the anti-cavitation plate should be right even with the bottom of the hull. The inverted V is only about 3/8".

Opinions are wanted here: Should the plate be even with the point of the inverted V or just a touch lower, even with the outside corners of the hull? It's not a big difference, but easy to adjust now and quite difficult later. I'm leaning towards a little lower, I would prefer the prop to bite a little more rather than mazimize speed by raising the prop.

My balsa core came today. Rolled up in a little 10x10x24 box. That was surprising. I'll document that process when it gets started. First, more taping, a transom trim, and a sole.

Fred in Wisc

Posted: Wed Jun 04, 2008 10:14 pm

by Daniel Huckleberry

Nice work. I have enjoyed watching this little build.

I built the TX18 and have some info for you on my engine. I am about an inch below the bottom of the hull. I would make sure your engine can get down below the hull. You can always adjust it up. You would hate to find all this out after you paint. If you plan for it, it will look natural now.

That is my opinion. Jacques even mentioned this in the study plans.

Good luck. I hope she turns out well and handles as well as my boat. The design is excellent.

Huck

Posted: Wed Jun 04, 2008 11:51 pm

by Cracker Larry

That's really nice work Especially with the scaling. Neat job

Opinions are wanted here:

It's too high and will ventillate. Now's the time to lower it

Posted: Thu Jun 05, 2008 1:16 am

by Fred in Wisc

I think it would be unwise to disagree with the voices of experience, Daniel and Cracker Larry. Back to the cutting guide and the circular saw. I'll cut the transom about 1 1/2" lower. That will put the anti cavitation plate about 1/2" below the hull bottom.

I feel pretty smart right now, I was on the right track with the engine height deal. Somehow it makes me feel a lot better to have some consenting opinions before sawing a chunk off the boat.

Spent some more relatively unproductive time pondering about how to insert the sole and decks. The clamping board on the transom extends 1" inboard, so if I tape all the frames in solid, I can't insert the sole without cutting extra big slots for the frames or putting it in in 2 parts, left and right, with a seam down the middle. But I'd really like to do the sole in one big piece. On the full size boat, the frames are made in sections. I thought it was for efficient use of material. It seems that it's also for sole installation.

I filleted and glassed the frame nearest the bow in this evening. The plywood was slightly warped from being stored, so it needed just a little persuading to be straight and level again.

Nothing exciting that needs pics today.

Fred in Wisc

Posted: Sun Jun 08, 2008 1:47 am

by Fred in Wisc

Short day at work on Saturday, so I planned on getting a lot done on the little boat this evening. Unfortunately we had weather that made me consider if any stitch and glue ark plans were available. Today our area got 2-4" of rain in about 3 hours.

Yesterday we had severe thunderstorms and tornado warnings, but beautiful weather once they passed. I was fishing with the neighbor kids an hour after the tornado warnings ended. Clear skies, in the 80's. Unfortunately real windy 20+ mph so rowing the canoe was no fun at all. Only one fish in 2 hours, but the kids were excited because it was a "predator". Sometimes I forget that even a little northern pike is exciting when you are 6.

Spent a couple hours today shop vac'ing water out of my basement and pumping about 5" of water out of my neighbor's basement. That really cuts into boat building time.

I did get a little time work on the boat. Cut the transom down about 2". This will put the cavitaion plate about an inch below the hull bottom. I was thinking about going a little higher, but there really aren't any high perfomance triple cup anti cavitating stainless props avaliable for 8hp OMC engines, so I decided a little more water over the top would not hurt. Best to be on the safe side there.

Also had time to fillet and tape the left side frames. Had a little epoxy left so I did the first right side frame too. Did these with woven tape for ease of fairing, since most of it will be exposed. I can see my fillets are definitely more consistent and neater than when I started. I am still no Cracker Larry or ks8, though. I am however, pretty sore from rowing yesterday. Feelin' pretty old right now....

The frame taping ponderiong is over now. The solution: The rear set of frames will be cut down and only extend up to the casting deck. That's only about 3" below the sheer. It will allow me to insert the rear deck under the clamping board, rotate it down on top of the rear frames, and then it will end just before the second frame. That makes the deck about 32" front to rear.

I'm wondering if I should cut the front edge of the deck flat or slightly concave. I'll usually sit off enter to the right to steer and I like that I can rotate farther to the left with a curved deck. Got some lower back issues, so I want to make sure I end up with a comfortable driving position. That is probably best answered by cutting a scrap wood deck once the sole is in.

I'll try to get some new pics up tomorrow. It's late, the camera is in the van outside, and it's thunderstorming.

Fred in Wisc

Posted: Sun Jun 08, 2008 2:01 am

by Fred in Wisc

Oh I forgot, got my long batten out and played with sheer lines. Have it close but not quite perfect yet, so that will come in a day or 2 or 3. It looks WAY cooler with the transom cut down and the sheer prettied up.

Fred in Wisc

Posted: Sun Jun 08, 2008 4:57 pm

by Fred in Wisc

Had a little time to work on the boat while baby was napping today.

After trying many options, I decided on the sheerline that looks best, traced and cut it. Just laid it out with the long batten, clamped it where it should be, traced the line. Then cut a little big with the cordless circular saw and planed down to the line. Actually cutting it only took about 40 minutes including moments of hesitation based on fear of screwing something up. The second side should only take 20-30 minutes.

Here you can see the left side is cut but the right is not. Hard to see in the pic but easy in person. The trim was about 3/8" at the transom, 1 1/2" in the center, and tapered to a point at the bow. Now instead of looking tall and fat, the boat looks lean and purposeful. A really big improvement.

You can also see the transom trim from yesterday. I set it up so the motor plate is about an inch under the bottom of the hull. Here is the transom from the inside, I will need to make the clamping board wider in the motorwell area.

It was interesting to take a look at the section of the transom to hull joint after cutting it. This one looks great, the other side had one little pinhole. So I'll post the pic of the perfect looking one.....

The red spots on the floor aren't blood this time. Just paint drips. There has been blood and sweat shed over the boat but no tears yet.

Here's how much I ended up trimming off, extra portion is sitting on the hull.

I also have a pic of the front frame trimmed to the height where the front casting deck will be installed. You can also see the fillet and tape job on the seft side frames, much neater than my first ones on the stringers. I'm not working any harder on them, just getting better at it as I do more of them. I think the lesson here is not to wait too long between boats, your technique suffers.

I am beginning to have some hope of actually using this boat before the end of this boating season. It may not be painted, but I think it's getting launched this year. (I ended up using my canoe for nearly 2 years in primer).

Fred in Wisc

Posted: Mon Jun 09, 2008 12:50 am

by Fred in Wisc

Well momma and baby went to sleep kinda early, so I got the rest of the frames filleted and taped.

Once it's set up, I'll take the level and transfer points for the sheer over to the right side, connect the dots and cut it. I'm pretty excited about that, really wanted to do it tonight, but it would be less accurate with the frames hanging loose. And the saw is pretty loud.

I think I am all done taping frames and stringers. Yeah! Oh, wait, except for the sones I have to add for deck support.

Next up, installing cleats on all the under sole stuff. Extending the clamping board and laying a couple layers of biax on the transom. Then foam. Then cutting out and installing the sole. Then.....Well I guess there's a lot more before the going fishing part.

Fred in Wisc

Posted: Wed Jun 18, 2008 4:12 am

by Fred in Wisc

Wow, it is WAY too late to be posting here, but I'm kinda wired from working on the boat tonight so this is a good way to wind down. Got a good amount done the last 2 days. My wife and daughter are visiting relatives out of town, so I get some extra boat time. Off work tomorrow, so time to git 'er done. Would have got more done today, but my wife's mother and father called, their freezer died, so I took them to get a new one, delievered it to the house, and horsed it down the basement steps. Not nearly as much fun as building a boat.

Thought about fishing tomorrow, but with all the rain we have had, the lakes are about 2' above normal, so the launches are really hard to get at. Lots of lakefront properties under water. One of my coworkers is planning on bowfishing for carp in a flooded section of town, you can actually see them swimming down the street. My guess is local law enforcement won't be too enthusistic about that.

Yesterday I finished gluing in all the cleats for the sole. That took a lot longer than expected. Leveling the outside cleats that glue to the hull was a bit challenging, especially in the bow. I only had enough clamps to do about half at a time, plus I was careful leveling everything so the sole is flat and square to the boat. The frames and stringers were pretty close, I only had about 1/8" of variation to even out.

I found it expedient to epoxy coat the bottoms and sides of the cleats before installing them, the access is so much easier than after. Sanded the drips and such off the tops. Tomorrow they will get a second coat, plus a coat on the top sanded surfaces.

Made a little piece to extend the clamping board down in the center, planning a little motor well, just to make it easier to tighten the motor down (clearance was pretty tight there) and to have a little more clearance when the motor is tilted up.

I measured and cut out the sole, then spent a bunch of time with the jigsaw and plane getting it to actually fit nicely. Definite disadvantage of not using the complete plans, you spend a lot of time measuring and figuring out stuff. And of course, I made an error transferring measurements, so I got to glue in a little patch where I cut one area too small. Working too late at night. Shoulda caught that. Since the sole used my last sheet of 6mm ply, I had to fix it. All I have left is a couple partial sheets of 6mm and almost 2 sheets of 4mm.

The sole is pretty thin, so it will be glassed both sides with 9oz woven fabric for strength and rigidity. For a 10' boat, the floor area is pretty impressive. About 7'7" long and 41" across at the widest point. Not that much taper either, it's 35" wide at the transom.

Tomorrow I will add the coast guard foam as well. It looks like I will have about 7 cubic feet with under the sole, in the bow (beneath a couple small storage compartments) and a pair of small transom boxes under the rear deck.

I better get to sleep, lots to do tomorrow. I promise I'll try to get some new pics up too.

Fred in Wisc

Posted: Mon Jun 23, 2008 12:54 am

by Fred in Wisc

After I got all the cleats glued to the stringers and frames, I let them set up for a day or 2, then sanded off the epoxy drips and stray wood flour putty on the tops of them so the sole can sit flat. Then I went back through and gave them another coat of epoxy to cover the areas I sanded through or missed previously.

Then I did a little calculating on the foam, had a little left over from my last 2qt kit, and a brand new 2 gallon kit. It looked like it would come out real colse, so I took some pink styrofoam scraps and put them down in the bigger compartments to take up some space. Then I mixed an poured lots of foam.

If's dang near impossible to estimate how much you need to put in a compartment to fill it. I ended up with several that needed a second dose of foam, and sometimes a third. Then I got impatient on the next ones and had a whole lot of extra up over the top. Best practice here is to do one or 2 compartments at a time, so you can trim the excess off and toss it in the next compartment.

Foam is so much fun. It's such an interesting reaction to watch. I left mine outside in 80 degree weather for couple days before bringing it into the basement, it certainly reacted faster than the stuff stored downstairs where it's about 65. Seems to yield more foam, feel fluffier, not as dense and hard.

Best tool for trimming was a flush cutting trim saw with a reversible handle so I could set it up to cut either direction. I tried to trim the foam just slightly high, going over it with the 36 grit on the longboard next so it's dead flush with the stringers. That will provide better support for the sole, so it does not flex. Got a few scratches in the stringers and cleats, so those will get a recdoat before sealing it up.

Ran out of foam before running out of empty spaces, so I have to get some more. Also need to build a divider in one bottom compartment to put my transducer and a drain plug. I also forgot to glue cleats to the transom to hold up the sole edge, so that will be among the next tasks.

Speaking of the sole, I laminated one side with the 9oz woven fabric. It's way easier to laminate flat panels. Looks like a pro did that one.

Only a couple days until the sole is installed, then I can move on to the decks.

Sorry, still having some camera issues. I'll get some new pics up here eventually.

Fred in Wisc

Posted: Wed Jun 25, 2008 2:07 am

by Fred in Wisc

Finally took a few pics.

Here is the sole, cut out and glassed on one side with 9oz woven cloth. It still needs minor trimming of the cloth and a little more clearance around a few frames. I want to make sure I have a large enough gap to get putty into it so it's completely filled in between the hull, frames, and sole where the frames come up through the sole.

Here is the hull with foam floatation mostly installed. The foam really stiffened up the hull. I still have to build some boxes for foam against the transom. Kind of a double duty thing, they will tie into the outer stringers, give support for the rear deck, stiffen up the transom a bit, and provide more volume for floatation.

I actually used a whole 2 gallon kit, plus some pink styrofoam, plus some leftover coast guard foam (about a quart) from my last boat to fill this. My wife is a little scared of small boats, so I know it's overkill, but it gives her peace of mind when I have kids in the boat. This thing should have about 550 or 600 pounds of flotation when it's done.

I still need to fill the 2 center compartments by the transom also, but there are a few bits to get glued in first.

One thing I learned: If you are using sheet styrofoam or something to fill in, make sure the expanding foam does not get under it, it will get pushed right out the top of the compartment.

Here is some detail of the bow area, with the foam trimmed nearly flush. I'm taking some time to trim carefully, even using the longboard and some 36 grit, to make sure I don't have any high areas that make the sole bumpy. In the bow, the angle required for cleats is really extreme, so I'm just going to level the foam carefully, cut it back about 3/4" from the edge of the sole, and put a fat bead of putty there to hold the front edge of the sole.

Here is the transom with the clamping board extension. I am planning to have a small area of the rear deck lower here to give some clearance for clamping the motoro on and tilting it up.

The glass work here is less than ideal, I actually wrapped one piece of biax from the inner hull bottom, up the transom, over the clamping board and onto the outside of the transom. I used some plastic sheeting and a lot of blocks and clamps to get it nice and neat around the 90 degree corners. Worked ok, but I have a few areas to fix. Mostly some air spaces in the corners, I'll shoot some epoxy in with a glue syringe and it will be fine. There are 2 areas where the fabric pulled farther away from the corners that I will trim out and reglass. You can see one at the top of the right side of the transom if you look closely. The other is at the left end under the clamping board extension.

I'm going to divide the right middle compartment so I can mount a through hull transducer like Cracker Larry did (that was slick), and a drain plug. Still need to glue in the divider and lay a couple layers of light cloth in it to make sure that area is well sealed. Then install a cleat on top of the divider and on the left side transom, pour and trim a little foam and it's time to install the sole. Exciting stuff.

Time to go to sleep now. Tomorrow is Daddy day (I have baby, my wife goes to work to actually talk with adults) so I had better get some rest.

Fred in Wisc

Posted: Wed Jun 25, 2008 9:03 am

by Dougster

Great pics, thanks for sharing. I'll be foaming in due time and appreciate the "tutorial". What a neat and creative build you've got going. Have fun on Daddy day

Currently learning about fairing Dougster

Posted: Wed Jun 25, 2008 9:49 am

by Mawrob

Nice job with the foam, Fred! I had a similar experience with expanding foam. Unfortunately in my case it was my fish box that got pushed up despite me standing on it to keep it down.

Posted: Wed Jun 25, 2008 6:07 pm

by Fred in Wisc

Thanks guys. The goal with the foam was to make Boston Whaler look like a bunch of little girly amateurs.

Fred in Wisc

Posted: Thu Jun 26, 2008 11:05 pm

by Daniel Huckleberry

Fred in Wisc wrote:Thanks guys. The goal with the foam was to make Boston Whaler look like a bunch of little girly amateurs.

Fred in Wisc

Don't worry! Being here already accomplished that!

Your boat looks great. I am anxious to see how she performs.

Huck

Posted: Wed Jul 02, 2008 12:04 am

by Fred in Wisc

Got a couple hours in on the boat today. Finished off the drain plug / transducer compartment shown above. Sloped the left and right sides in at about a 60 degree angle with 4mm ply. Put a few layers of thin woven glass in it to seal it up nice.

Got the transom boxes cut and tack welded in, hope to be able to finish those up tomorrow. Need precoat, fillets, and probably some 9oz (getting concerned about running short of biax for the outer hull.) They will provide support for the transom and rear deck, an anchor point for the rear deck framing, and about a cubic foot of flotation.

Filled the last 2 floor compartments with foam. Need to finish trimming the foam flush before installing the sole. I was trimming today with the Fein with the flush trim blade and it works amazing for that. I'm pondering building a jig to allow me to trim precisely in one shot. I'll take pics if that works out.

Once that's done I'm going to try recruiting my wife to help lay the sole, since that will require a lot of glue to be laid down fast. I don't want that going off before I'm done spreading it all.

I'll get pics tomorrow if I can.

Fred in Wisc

Posted: Fri Jul 04, 2008 8:34 pm

by peter-curacao

Fred in Wisc wrote:Thanks guys. The goal with the foam was to make Boston Whaler look like a bunch of little girly amateurs.

Fred in Wisc

It look's like a Whaler the hull that is or am I wrong? anyway very nice boat Fred

Posted: Fri Jul 04, 2008 11:11 pm

by Fred in Wisc

Peter,

There are similarities, the Hickman Sled design was modified by Boston Whaler years ago. It's an interesting story, google Hickman Sled and you'll get all kinds lf links.

This is Jacques HS18 scaled down. A variant of the TX18.

Fred in Wisc

Posted: Wed Jul 23, 2008 1:33 am

by Fred in Wisc

After a couple weeks with lots of time at work and lots of summer vistiors (plus 2 short fishing trips finally), I got some more done on the boat.

Took my little girl Abby for her first ride in a small boat. She loves it. Great. Also is very interested in the fishing equipment, wants to crank it in almost every cast. Is terrified of fish however. We'll work on that. Here's daddy's little helper, she'll be 2 next month.

Got the motor height sorted out. It may be a little too low, but I will sacrifice a little top speed for better handling and resistance to ventilating the prop. I can always epoxy a strip of 1/2" ply to the transom top if it's way too low. The holes you see in the transom are from where I screwed it together when I laminated it up. I drilled them out to 3/8 for the first 1/4" of depth, that way I know for sure I can get them filled solid with putty when I glass the outer transom.

Got all the foam trimmed down and sanded level to the top of the frames and stringers. Before installing the sole I vacuumed it carefully and rolled a coat of epoxy over the foam, frames, and everything. Might as well seal it all up so I never have to get under that sole again.

Built some boxes in the transom corners. They will support the rear deck and also strengthen the transom. They are taped inside with biax and laminated with 9oz woven. I need to do some sanding and filiing before they get glassed on the outside as well.

Put in a little well to mount my sonar transducer and put in a drain plug. There are several layers of cloth on the bottom of this so I can cut the wood out when it's flipped and laminate in a solid glass piece to shoot the sonar through. Thanks to Cracker Larry for the through hull sonar idea.

Actually installing the sole took far less time than the prep work. I sanded the stringers, recoated them with epoxy. Planed the edges of the sole to make sure it would not create any hard spots. Wiped the bottom of the sole down with solvent, I glassed it weeks ago. Sanded the frames and hull sides where the sole will be taped in.

Actually gluing it in was pretty easy. Mixed up a 24oz batch of epoxy with slow hardener. Measured very carefully, don't want to have to scrape that all off if it doesn't cure. It was a little scary mixing that big a batch, I usually only use a few ounces at a time. Thickened it with about a third of a pound of wood flour. It took a while to stir that all in. Then dumped it in the big paint tray so I wouldn't get a big expensive smoky paperweight.

Used a bondo spreader to lay a little thicker than normal layer of glue on all the stringers, frames, and hull side battens. Then just laid the sole on. Found one little hard spot, trimmed it out with the Fein and a razor knife. Then got out a collection of assorted SHS (Some Heavy Stuff) clamps to hold it down while it cures. Ran short of SHS clamps and did a quick search of the basement to find extras. Luckily they are all over, you just need to find small heavy things that your wife won't kill you if they get a little epoxy on 'em......

We'll see how it turns out in a day or 2.

Also found some warp in the front frame, causing it to bow toward the bow. I cut the glue joint with the Fein (you just have to play with one of these at the Woodworkers Store, they are so cool) and a hacksaw blade. Put a little plywood chunk at the top to straighten it out, and put a new fillet in the gap. Should be good as new tomorrow.

That's it for now.

Fred in Wisc[/img]

Posted: Wed Jul 23, 2008 8:58 am

by Cracker Larry

Looking great Fred

You won't have to ever worry about sinking

You are really making fast progress. Nice work.

Posted: Wed Jul 23, 2008 11:12 am

by jgroves

Fred,

Been following your build and the boat is looking great! Also, beautiful little helper you have there! Keep up the good work.

Jeremy

Posted: Wed Jul 23, 2008 8:23 pm

by Rob Eades

Fred, you old dog.I thought I was the only guy that used my secret shotgun shell stash (hid in the garage) to hold down a big epoxy job.

Only a clays shooter has that kind of stash.Whats your game? sporting and skeet here.It becomes an addiction quick,kinda like boat buildin'.

I won't tell your wife if you promise to do the same.

sorry for the hijack guys,

Rob

Posted: Wed Jul 23, 2008 11:56 pm

by Fred in Wisc

Pulled the SHS clamps today. The floor is smooth, level and solid. Shortly I'll fillet in the edges, tape and lay a layer of 9oz over the whole sole.

The addition of the sole stiffened the hull up dramatically. Before it felt pretty solid, but you could get it to twist by pulling up on one corner. Now it's rock solid. No twist. Wow. I don't even have the exterior biax layer on the hull yet. Once it's fully glassed this thing will feel really bulletproof.

I got inside and walked around, played a bit with furniture layouts. Since the hull is a bit heavier than I originally thought, I'm pondering minimizing the interior buildout to reduce weght and allow a bit of extra versatility. Probably just a little front deck, maybe 2 bench seats, and some little trays over the transom boxes (store sundry tackle and a place for the fish locator).

I was planning some narrow side decks, but they will reduce room in the cockpit and add weight, so I think I'm gonna skip those. I am going to work on a pattern to finish off the top of the frames in a pleasing way.

Thanks for the kind words Cracker and Jeremy. In person you can see all the flaws, but if I start to obsess over every little thing and try to build to the CL/ GK108 level of finish, this thing will never launch. So I'm making sure everything is real strong and looks, well, pretty good.

Rob, not so much shotgun sports- there's 11 bricks of 22's in those clamps. Only 8 boxes of shotgun shells. My niece and nephews started hunting with me the last 2 years, so I have been trying to get them out to the gun club to practice more. 4 teenagers can go through a lot of ammo in a couple hours. We'll go through lots of 22s, a few boxes of centerfire rifle shells and a couple rounds of trap. I just want them to be proficient so they have some success when we hunt. I've been bulking up on ammo when I find it on sale, the cost increases in that have been ridiculous the last year or so. Actually started using handloads for most of my rifle and pistol shells. I have a hard time knowing each trigger pull costs over $1 with factory ammo.

I was gonna use my ammo storage box as an SHS clamp, but when I lifted it (grunting likd a caveman), I decided my little stands under the boat would not like that muc weight.

Actually my wife suggested I build a locking cabinet for ammunition. She has some idea there is a stockpile, but not to what extent.

No sweat on the threadjack, the builder galleries are more entertaining and threadjack friendly than the technical how-to sections.

Fred in Wisc

Posted: Fri Jul 25, 2008 6:19 pm

by Fred in Wisc

Had some time to work on this last night and today.

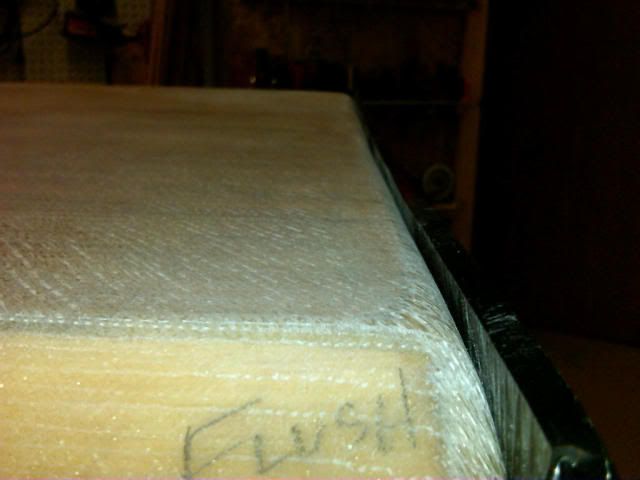

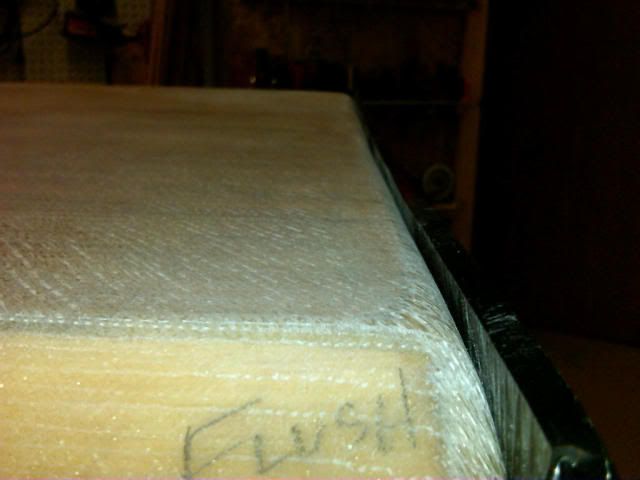

Here's a pic of the sole, it turned out well. This is after I did a bit of sanding, so it's dusty. Just sanded the existing epoxy to get ready for taping and glassing.

Here is the rear well for the transducer and drain plug.

Here is the tape all precut and laid out. Not a ton of time to work today so I had to be efficient. I used 6" woven tape cut in half so it's 3" side. Would have preferred 6oz biax tape, but I discovered I'm out of it. Forgot to order that a couple weeks ago. Used full 6" tape on the corners of the transom boxes and on the transom to sole fillet.

Filleted, taped and then applied a layer of 9oz woven extending up about 8" up from the sole. One little problem: I mixed up a 12oz batch of epoxy with slow hardener, noticed I missed a fillet. Poured out most of it into the paint roller tray, saved about 4 oz to mix up wood flour putty. Took a little while doing the putty, then spread out the wide cloth. Started to pour the epoxy onto the cloth when I felt it was pretty hot. Dang. Started to gel a little already. But it was too late, it was on the cloth. Squeegeed furiously to wet out the cloth before it set up. Poured more newly mixed resin on top and squeegeed it again. It kind of worked.

There are a few patches in the middle of the sole where it's not completely wet out. You can see them in the middle third of the sole from about the front of the transom boxes to a bit past the next frame. I'll try peeling it up there once it cures. If I can, I'll cut it out and redo it. It looks pretty much wet out so I think it's probably ok, and it's in a low stress area.

That's it for today. Taking some of my scouts to camp tomorrow, so I probably am done with boat work for the weekend.

Fred in Wisc

Posted: Sat Jul 26, 2008 11:01 pm

by Fred in Wisc

Once the epoxy hardened, I went over the boat again to check my work. Got a few bubbles, nothing too major. You can see the one on the front seam of the sole and transom box on the pic. Wish I'd caught that earlier....

The areas that did not wet our so well from the gelled resin seem to be ok. Looks like the weave is not completely wet out, but well stuck down to the sole.

Got a bunch of runs, drips, and little puddles of resin that I missed before. Odd how that gets overlooked when it feels like your back is gonna snap from working 3 hours at knee height.... Got some sanding and scraping to do and this will be just fine.

After that, finish up the inner transom, a little bit of interior furniture, rubrails, and the biax on the outside of the hull and we'll be ready to fair and paint.

Fred in Wisc

Posted: Sun Jul 27, 2008 5:37 pm

by chicagoross

Fred, I know how your back can announce that the drips and runs are not a critical element of the boat. I built a few boats in the Philippines, singlehanded except for sanding and painting; for those tasks I had an unlimited supply of workers who wanted to finish the boat for $5/per day plus lunch and snacks. The more coats, the better for them.

On my own completely now, finished the primer and starting the real paint, there have definitely been a few drips and runs and blobs that could have been sanded better - I was fortunate to have realized from the beginning that my current boat was going to be "workboat finish". But there's a difference between 18 foot with cabin and a small ope skiff - you'rre will have to be perfect!

Posted: Sun Jul 27, 2008 6:34 pm

by Fred in Wisc

Perfect, no. Pretty good, yes.

Wow, Phillipino sanding help is way less expensive than chiropractor visits!

Fred in Wisc

Posted: Tue Aug 26, 2008 11:41 pm

by Fred in Wisc

After nearly a month with no progress, I finally got some more done on the boat.

Got one rubrail glued on. 3 layers of 6mm Okume. The sheer is pretty sweet, IMHO. Now I have to wait for that to set up, plane the drips off, and match the oter side rubrail real carefully with the level. I kinda trust measuring, but the level never lies. Plus measuring errors always seem to get worse as you go along, the level brings it all back into alignment again.

After much pondering, I got my front deck layout mostlyfigured out. Got the deck rough cut, cut down the bow to fit it in level, and installed cleats to hold the edges.

I'll get some pics up shortly. I might have to clean up the shop first, or you'll make fun of me. My wife "borrowed" my shop trash cans and now there are a lot of stir sticks and gloves glued to the floor.

Fred in Wisc

Posted: Wed Mar 25, 2009 1:40 am

by Fred in Wisc

Well, so much for getting some pics up "shortly". It's been nearly seven months. My thread was on page 3. I'll try not to let that happen again.

Recently life got kind of complicated. In September I sold the majority of the company I started in 2001. Figured the economic outlook was not so good for the small independent guy, turns out that sure was right. Dang, wish I'd had the foresight to get my 401k out of the stock market too.....

Anyway I'm working in one of my partner's other companies now. Quite the change to go back to reporting to somebody else. Of course the part where you know you get money every 2 weeks is pretty nice. My wife likes that a lot.

Did a little work on the boat through fall, spent time fishing and hunting with the neighbor kids and relatives. Got to sit on the stand with my 14 year old niece when she shot her first deer. That was awesome.

Unfortunately, my dad took a bad fall down the basement stairs, ended up spending 50 days in thekhospital. Has a brain injury. That's improving a lot, unfortunately when they were doing MRIs for that, they found a mass in his lung. Turns out to be small cell lung cancer, the nasty kind, and already spread into other organs. Doc says they can't cure it. Dad and the family both decided not to do the chemo, he'd rather have as much good time as he can instead of stretching it out being sick and miserable. Only 63, just doesn't seem fair.

Amazing how your priorities get adjusted when you face the loss of someone important in your life........

Anyway, been driving 400 mile round trips to be up visiting him and mom about every weekend. He's actually doing pretty well, in a rehab home just a couple blocks from his home so they can monitor him. He lost about 2 months of memory, but he's detoxed from all the smoking and drinking he's done recently (was in a bad construction accident years back and hates the pain pills, prefers the Bud light) and now he's the nicest guy he's been in years.

Had great weather last weekend, took him out for lunch and a drive with my little girl.

So I haven't been working on the boat much. But spring is coming and in Wisconsin that means walleyes. Now I'm itching to get it done....

Here's some progress:

Got the tops of the frames contoured nicely, rubrail on (3 layers of 6mm). Unfortunately I trimmed the frames on the other side a little short so I need to glue in some little pieces of ply to get the tops contoured right. Dang.

Got the bow storage compartments near done. Put some 3/8 ply sole in those with cleats, foamed underneath, 9oz woven on both sides. Took some ti9me to get them to fit up nice and sit level. Cutting the access was real easy, made a template, clamped it on and cut with a router and a top bearing pattern bit. Flipped it over to mirror image the other side. Slick. I was kind of dreading that job, afraid I'd screw it up on a piece that's really visible, but it went near perfect and took under an hour. More sanding and some pigmented epoxy and we'll be ready to glue the top on.

Got the rear deck cut and fitted, glassed on the bottom. This is regular pine exterior, wast planning on using some balsa core there, but my experience with it was not so great. Gotta do some more research to lay that up right. Don't have the patience right now. Turns out if you don't edge glue all the balsa blocks together it's not very strong. And it soaks up some serious epoxy, laying it up in one shot is a bad idea- you should probably precoat, set that cure a while and then laminate. Anyway, I have about $50 materials tied up in the unusable piece you see leaning on the wall in front of the boat. At least the dumb tax on that was pretty low, I've messed up way more expensive stuff before.

The exterior pine ply rear deck is pretty light and I will make sure it's completely isolated from the hull with epoxy so if it ever has problems I can cut it out and replace.

For support, I laminated up 4 layers of 6mm about 1 1/2" high and ran it between the flotation boxes under the deck. I'm still a little unsure about putting this in. It started out a lot bigger, I've trimmed it down about 3 times so far. I like the higher deck for casting, but I don't want to take all the floor room up. As it is, the deck is only about 9" off the sole, so it will fit my small gas tank and a little bit of gear underneath.

That blue scraper is from Rockler. Best $20 you'll ever spend. Highly recommended.

That's about it for now.

Keep Dad in your prayers if you'd be so kind. I'm planning on missing him for the next 30 years, but want to make sure I've got him the 3 million after that......

And go see your family if you haven't lately. That boat can wait one weekend.

Fred in Wisc

Re: Little Hickman Sea Sled

Posted: Fri Mar 27, 2009 10:28 pm

by Fred in Wisc

My thread vanished with the forum change, just checking if a new post will bring it back.

Fred in Wisc

Re: Little Hickman Sea Sled

Posted: Fri Mar 27, 2009 10:38 pm

by Fonda@kauai

Boat looks really good Fred. Sorry to hear about your dad. It's sounds like you're spending some quality time with him though, and that's what's important in life. Aloha nui loa.

Re: Little Hickman Sea Sled

Posted: Sat Mar 28, 2009 1:09 am

by TomW

Best of wishes to your Dad and your family Fred. Life does tend to throw us some unexpected loops into the boat building sometimes doesn't it. Good luck to you and to him and all of your family as they enjoy what time you have with him.

Tom

Re: Little Hickman Sea Sled

Posted: Sat Mar 28, 2009 2:00 am

by Fred in Wisc

Thank you, gentlemen.

Fonda, where are you on Kauai? Been there 3-4 times, it's one of the most beautiful places in the world. My wife bought a time share in Poipu before we got married. We always end up looking for ways to stay, but it's too far from family.....

Fred in Wisc

Re: Little Hickman Sea Sled

Posted: Sun Mar 29, 2009 11:53 am

by Dog Fish

Fred, very sorry to hear of the sad news about your Dad. I will keep him in my prayers. I know your pain I lost my Mom at the age of 60 from complications of breast cancer, just to dam young. Stay strong my friend. Good luck with your build and she will be done in do time.

Brian

Re: Little Hickman Sea Sled

Posted: Sun Mar 29, 2009 11:55 am

by Dougster

Hard news Fred. I've enjoyed your posts and the creativity in your build. I can do no more than wish you courage and your Dad a smooth passage.

Says we live in little boats on very big waters Dougster

Re: Little Hickman Sea Sled

Posted: Sun Mar 29, 2009 8:18 pm

by Cracker Larry

Our prayers are with your Dad and your family, Fred. May the passage be easy. I recently lost mine and I feel you grief. I just picked up his ashes on Friday. We were supposed to spread them in the ocean today, but the wind has been blowing 40 kts for a week, so he's still sitting on the shelf behind me. I guess he isn't quite ready yet. For everything a time.

Re: Little Hickman Sea Sled

Posted: Mon Mar 30, 2009 9:47 pm

by Fonda@kauai

I live at the base of Mt.Wai'ale'ale in Kapaa. I love Poipu and Koloa Town, so pretty on that side. Let me know if you head out this way again and we can fish or whatever...

Re: Little Hickman Sea Sled

Posted: Mon Apr 06, 2009 9:54 pm

by Fred in Wisc

Took a road trip this weekend, up to visit Dad for his birthday. It was a good time , about 3 dozen friends and relatives in Mom's little house...... Anyway a long trip is good for pondering and the rear deck in the boat still wasn't making me happy. Just seems to take away too much floor space. I know I want a little deck to hide the gas tank under and give me a raised area for casting (not real often, but there are times when it's an advantage).

A couple hours of pondering turned into 10 minutes of measuring, 2 minutes of sawing and here we have it:

I still need to round the edge of that, but I'll do it at the same time as the front deck.

I will likely be putting in a lightweight pedestal seat, located pretty far forward. As far as I can comfortably reach the tiller handle, that is. Should improve the balance for the times I am alone in the boat.

Seemsmy stuff always evolves as I'm building it, I have a lot of respect for guys who ca plan it all out ahead and execute that plan. It woule be a lot more efficient. One day I'll build one of these boats right to the plans. I bet it's a lot faster....

That's about it for tonight. Might get the front deck assembled tomorrow, my wife is going visiting. Have to see if baby is cooperating....

Fred in Wisc

Re: Little Hickman Sea Sled

Posted: Tue Apr 28, 2009 10:59 pm

by Fred in Wisc

Made a little progress the last few weeks. Been spending a lot of time up north visiting Dad while I still can so the boat has taken on a lower level of importance. Got the flu this Sunday, not the swine won on the news. Felt like the tasmanian alien death flu or something. Pretty unpleasant. Was advised not to go back to work until all symptoms subsided so I sat home yesterday feeling kinda out of it, then today feeling pretty good indeed (but possibly contagious). So I got to work on the boat some. When life hands ya lemons, make a Hickman Sled......