Page 1 of 1

The Plytanic 2.0 - FS17 Build

Posted: Tue Nov 21, 2017 11:47 am

by silentneko

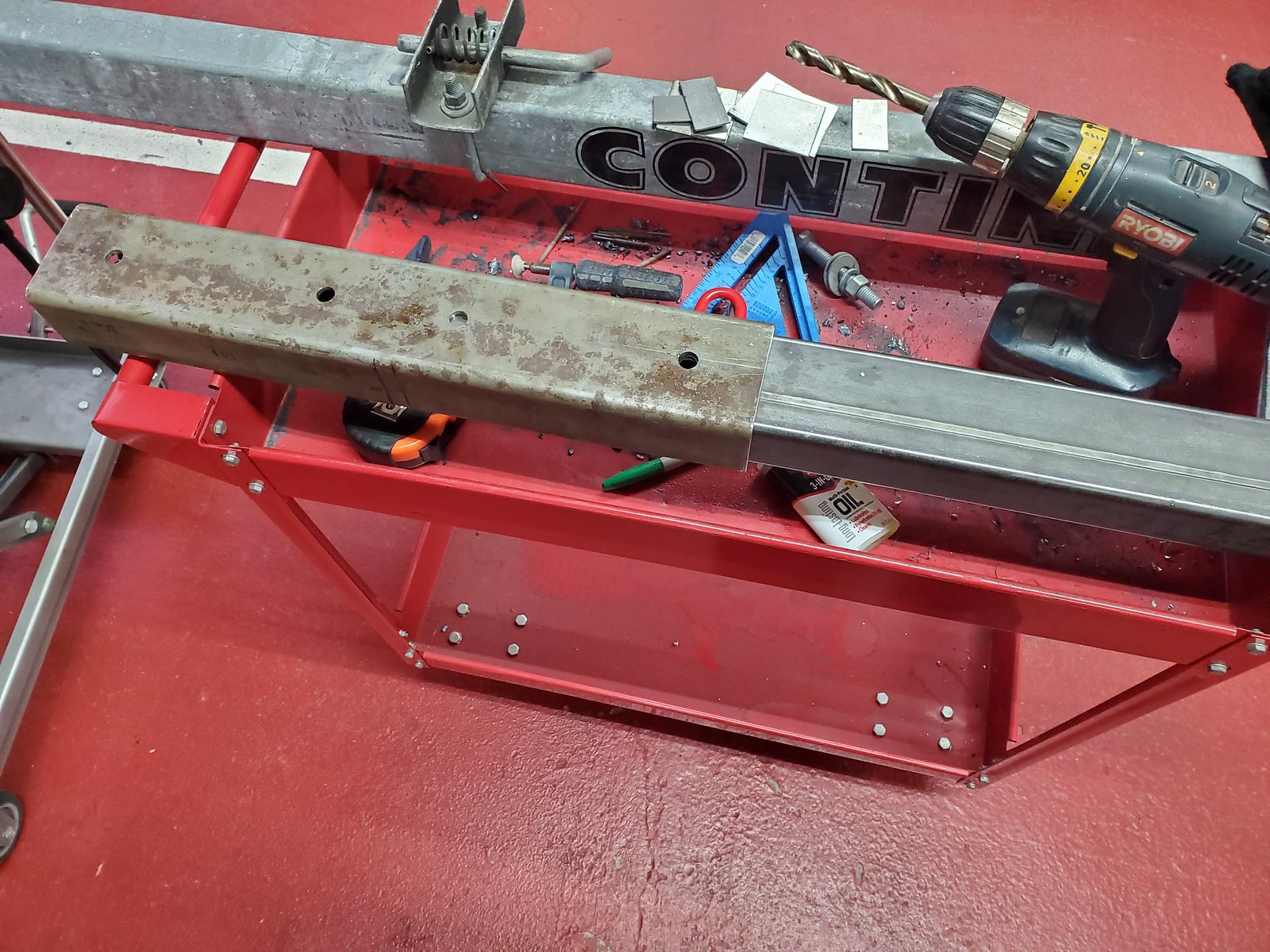

FS17 build, Take 2, lol. As some of you guys know I ran into some trouble building my last strong back and frames. I had something off to where I couldn't line up the stringers correctly. This could be because I tried to modify the stringer height, or transom thickness. Either way it bothered me enough to where I just wanted to start over. I'm going to build the shell to plans then make some modifications after the hull is flipped over.

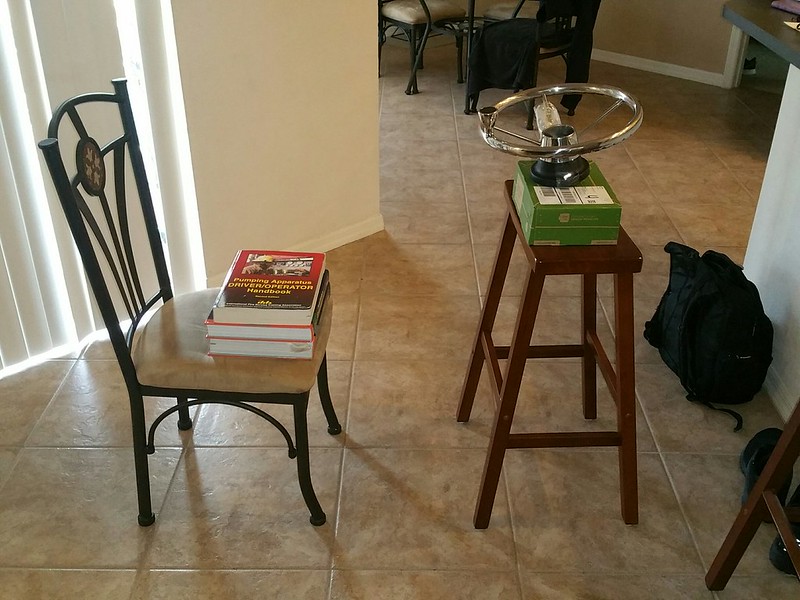

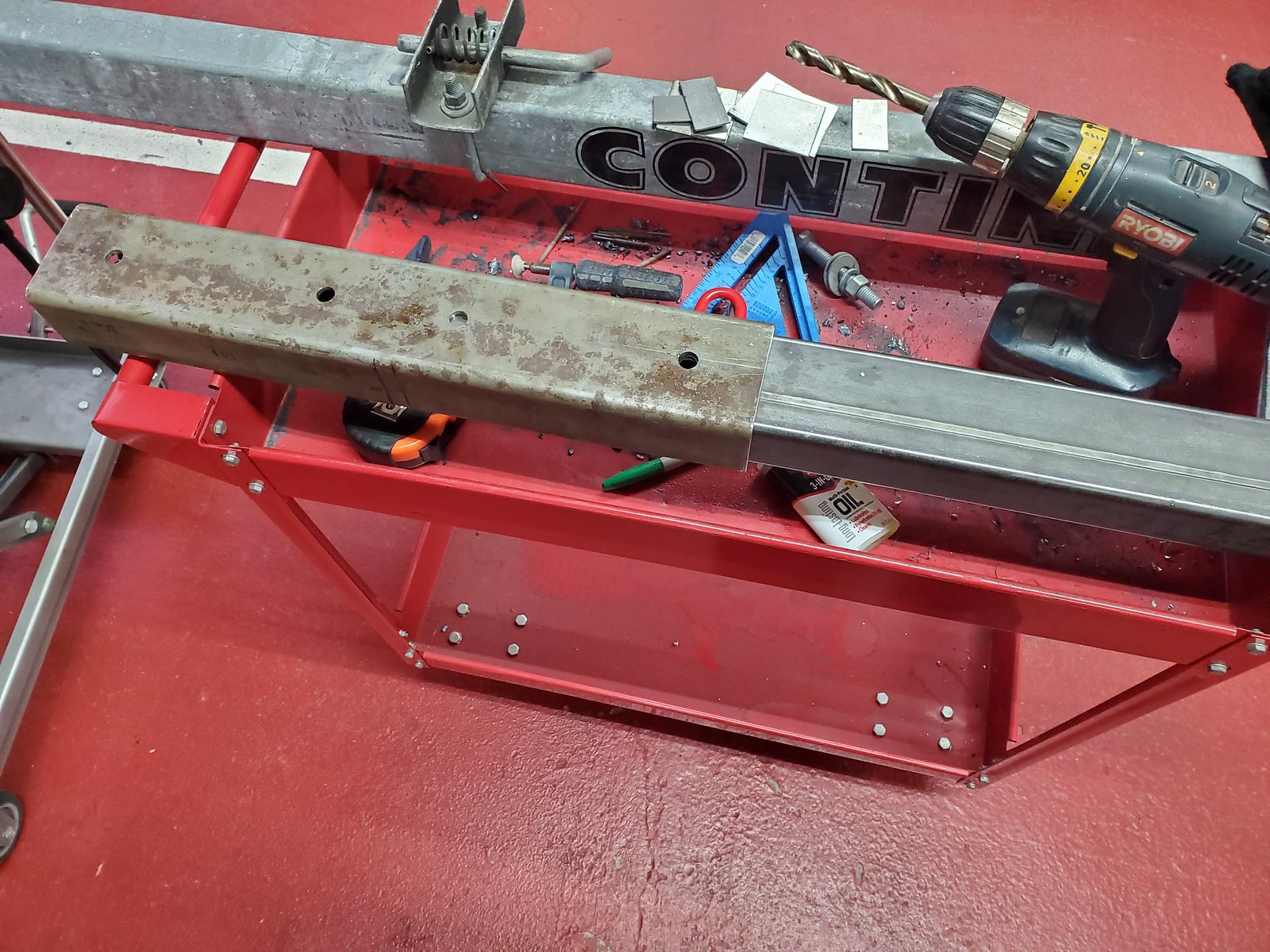

So the last strong back I tried using 2x4x8's as they were the best thing I could find. Even though I leveled and straightened them as best as I could I can't be sure the issue wasn't there. I'm not willing to try that again so I decided to build my own strong back runners.

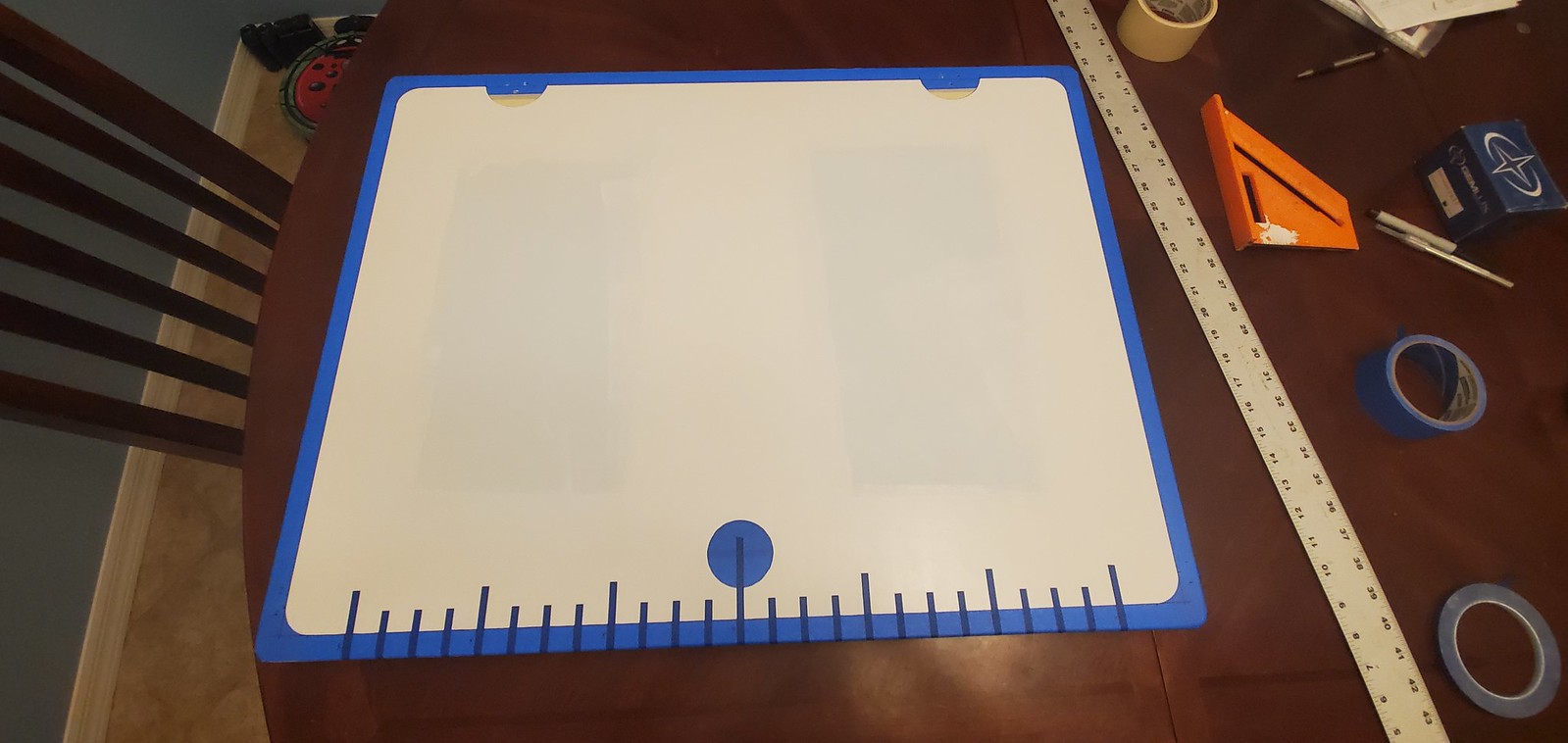

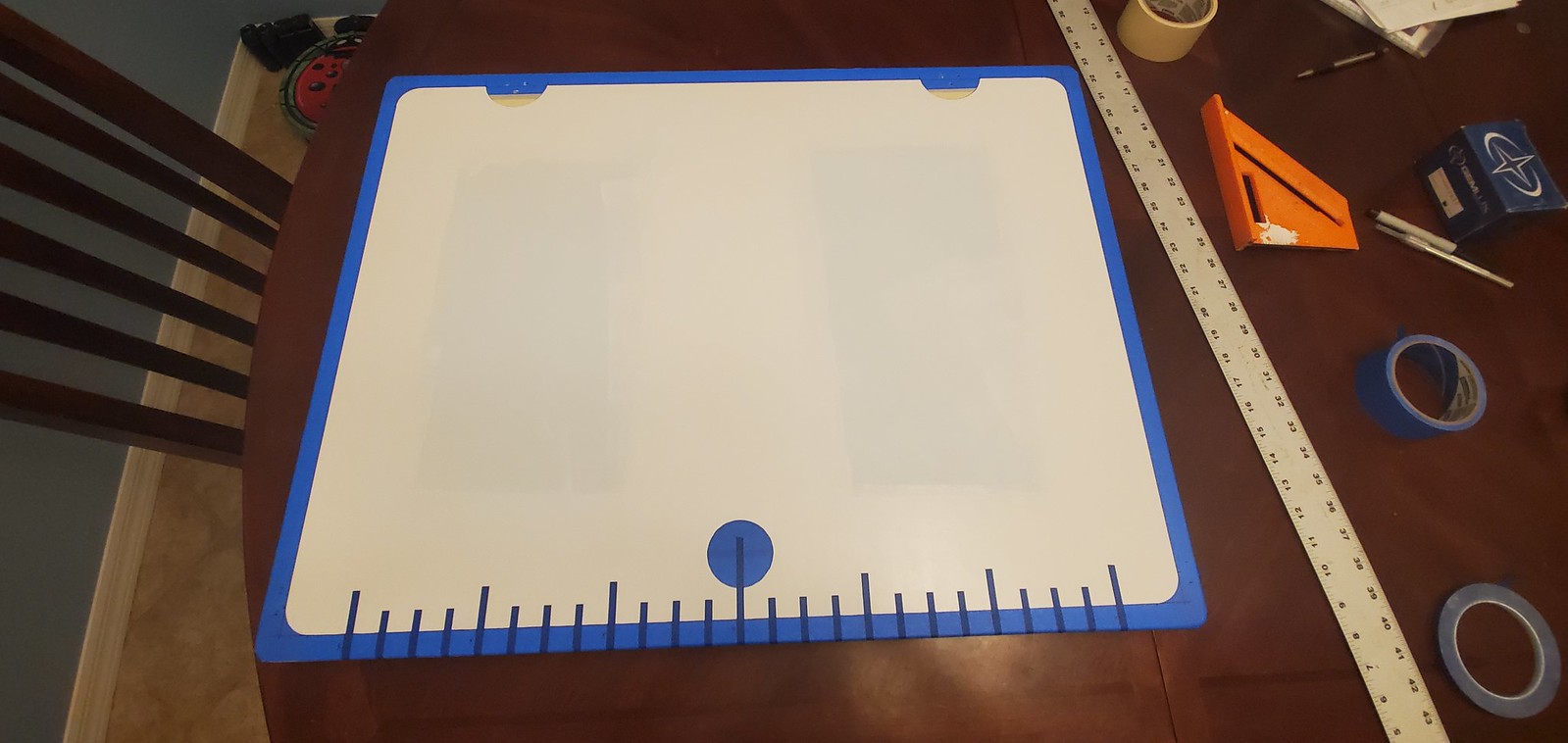

I got a piece of Sanded ply. Cut it into 6" strips and laminated it together.

Even after all that I wasn't 100% happy, so I snapped a chalk line and cut them down to 5.5". This is as straight as I can possibly get it!

A couple of notes here. I was amazed how many screws I used building the previous strong back. If you think you have enough, double it.

Also I went to go buy one of those big nice drywall squares to cut my new frames with. Well they are pinned together parts to make the 90 degrees, which I don't like, I wanted a one piece tool. I decided to check them prior to buying, and by the time you are 48" out they were at least 3/16" off! I guess drywall doesn't need to be that accurate, but I'll stick to a t-square and ruler.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Nov 21, 2017 2:29 pm

by Fuzz

Good move, now you will not have something bugging you in the back of your mind for the whole build. The base for your frames is like the foundation of your house, if it ain't right nothing is right.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Nov 21, 2017 3:10 pm

by TomW1

Like all things dry wall squares depend on the pride of the manufacturer. My builder would never allow 3/8" difference over 4' nor would I. There are squares out there that are dead on but you pay for them. When I was laying out my C17 which I never finished I double checked it for square and it was right on, but it cost me $$.

Tom

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Nov 21, 2017 3:18 pm

by Jaysen

All edges on drywall are covered. And mud covers just able every possible error. So yeah... no need for square.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Nov 21, 2017 4:20 pm

by silentneko

I was hoping to get a lot done today, but the kids are off of school. I did manage to get the strong back finished.

It is square to withing 1/16", and level across 6 fields length wise and 4 across the beam. I don't think I can get it any closer.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Nov 21, 2017 4:22 pm

by Jeff

Good work silentneko!!! Jeff

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Nov 22, 2017 2:56 am

by OneWayTraffic

There’s a trick for right angles on this website. Use a full sheet of ply. Line it up and slide it across the other sheet.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Nov 22, 2017 6:56 am

by silentneko

I was trying to do something similar ealier, but I'm out of room. My garage inventory has grown over the years, tools, rolling tool chest, standing saw, work bench..... I under estimated the amount of room the FS17 needed to be built. Not a big deal, I can make it work, but I'm suckling in my gut to get around some places, lol.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Nov 22, 2017 8:52 am

by Marshall Moser

You can also use trigonometry as a "square".

A 3"x4"x5" triangle is a right triangle.

Any multiple of this holds true, 6x8x10, 9x12x15, 12x16x20.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Nov 22, 2017 9:40 am

by silentneko

I did that to double check my last frames. Mostly I'm using a large framing square (big metal triangle) and a thick ruler, which work out very accurate. I saw a drywall T recommend on one of the old tutorials here so figured I'd try.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Nov 22, 2017 2:54 pm

by joe2700

For getting the frames level and aligned on your strongback I find a laser level the best tool. Not sure if you used that the first time or not. There are some perfectly good ones for less than $40. I like the hammerhead on amazon myself. If's a good sanity check that all your measurements are right, because it makes it very obvious when something isn't in line.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Nov 22, 2017 6:53 pm

by silentneko

I wish you posted up a bit earlier on. I went looking for a laser level like that, but only found expensive ones so I didn't buy. I used a regular level, plumb bob, and 72" ruller to level everything. I'm fairly certain the frames being out of level wasn't the issue.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Nov 26, 2017 1:25 pm

by silentneko

Well a few days ago I decided to stop for the holidays. Originally i was going to work every little chance i could find, but being so I had tume to order that laser level. We will see how it works out. Thanks.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Nov 26, 2017 9:42 pm

by silentneko

I was able to sneak out to the garage for a bit. I was able to finish cutting out the frames. I forgot how much heavier MDF is then plywood or OSB, and it cuts slower, but it's done.

Everything lines up well, like last time

I also cut out the new test stringer. I put the laser level to good use. I know this one is straight and to plans.

I'll be gone the next few days, but hopefully I'll get the frames up by weeks end.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Nov 27, 2017 9:24 am

by pee wee

Here's hoping it goes together right this time. Those lasers may not be magic, but they sure make life easier when it comes to alignment and leveling.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Nov 27, 2017 9:47 am

by silentneko

I have to cut out the the motor well sides, then I'll use the laser to realign the strong back, and attach the frames. I already attached the bow mold to frame A so it should go quickly.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Nov 27, 2017 10:45 am

by jacquesmm

silentneko wrote: ↑Wed Nov 22, 2017 6:53 pm

I wish you posted up a bit earlier on. I went looking for a laser level like that, but only found expensive ones so I didn't buy. I used a regular level, plumb bob, and 72" ruller to level everything. I'm fairly certain the frames being out of level wasn't the issue.

See this for a very cheap but very accurate waterlevel:

http://bateau2.com/howto/foam3.php

I also use a cheap laser level but the one with the water hose is more accurate and easier to use.

You fasten one of the tubes somewhere (on the wall?) and move around with the other end.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Nov 27, 2017 2:47 pm

by cape man

I learned about using a hose level like that during pond construction training as a Peace Corps volunteer . You can level anything as big as the hose will reach. Should have seen the eyes on some of my employees here a few years back when I pulled the trick out of the hat while building a large tank system. Today...I use a laser!

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Nov 29, 2017 8:45 pm

by silentneko

Well I'm basically back to where I was before I started over. I used the laser level to line everything up. I'm not sure if it really made anything easier as it took a while to setup.

Everything is all lined up and ready for the next step.

Stringers are a little off still, but close enough.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Nov 29, 2017 11:34 pm

by TomW1

It looks good from here. Carry on!

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Dec 03, 2017 2:42 pm

by silentneko

Not to much to report just yet. I cut out the first layer of the transom, but came into some question regarding the size of the clamping board. After some chatting back and forth I determined the best course of action is to go back to my original plan of extending one of the layers to full length, and then making sure the clamping board extends down a few more inches. This should give me more then a big enough clamping board to do what I need and increase the strength of the transom quite a bit.

As far as the stringers are concerned, I'm going to keep them the same for now. I figure moving them up 3/8" will not effect the height much. If it changes the height by 1/64" I would be surprised. I have some days off coming up, it's time to get moving on this.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Dec 03, 2017 6:09 pm

by Fuzz

Good move with the stringers. If you really want to raise the deck you can do the dado a 2x thing when you get ready to install cleats. See AA's build where he installs his cleats.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Dec 03, 2017 7:31 pm

by silentneko

I'm still planning on stretching them an inch, but I'll build the final stringers after I get the hull flipped and make sure they fit right. For now they are close enough.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Dec 05, 2017 3:46 pm

by silentneko

Not to much progress as I slowed down a bit to finish the transom. Unfortunately I'm working in tighter quarters because my garage is loaded down so I have to hurry up and wait for the resin.

Yesterday I cut out the second layer of the transom and the 2 layers for the clamping board using a router so they match closely. Today I am working on laminating everything. I always start with a thin coat of neat epoxy that I let set for at least 20 minutes. I see a lot of guys skip this step and have issues later because the wood soaks up so much and can rob epoxy from glass and other things.

I loaded on the thickened epoxy, spread with a notched trowel and weighed down the clamping boards. I used a mix of wood flour, milled fibers, and silica for the mix. I'll need to do 3 separate bondings to make sure it comes out well. Transom panel to transom panel, clamping board to clamping board, then clamping board to transom. The first two are setting up now.

I've never used MarineEpoxy before but seems to work well. My only complaint, and it's minor, is the color of the resin, or lack there of. Both the hardener and base are nearly clear, so when rushing you still really need to pay attention. I'm used to the hardener being honey colored, so I might need to switch back for any bright work I do to get the look I want.

Here's a tip I learned. Always keep your roller or brush until everything is cured. It's a great indicator that everything is going right and lets you quickly see what stage everything is in without putting finger marks in your glass. I just keep mine in the glove I take off, when it's rock solid it goes in the trash.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Dec 05, 2017 3:56 pm

by Jeff

Off to a strong start!!!! Happy holidays, Jeff

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Dec 05, 2017 4:35 pm

by jacquesmm

Corrected: I was wrong when I wrote the comments below. I must have been thinking of another one of my designs.

Silentko is on the right track.

If the pictures show the whole transom, all is fine.

If it is the clamping board, at the top, the clamping board is supposed to be straight across, not follow the shape of the upper part of the transom.

What you did does not hurt but now I understand more about our previous discussion.

I will draw a picture of the clamping board and transom in perspective, that should make it clear.

I need about one hour that.

In the mean time, no worries, you can build the transom the way you did it.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Dec 05, 2017 4:52 pm

by jacquesmm

Corrected, see my other posts. The FS17 is designed with a clamp that goes all the way up to the top of the transom.

Here is a drawing of the transom and clamping board (no perspective):

Number 1 is the transom outline, the outside layer, only one layer.

#2 is the designed clamping board, the one shown on the nesting. It has two horizontal straight edges spaced (in this case) 12". You had enough ply for 3 layers like that.

#3 is the the clamping board we discussed, the one that goes all the way to the bottom.

The upper edge of 2 and 3 is the edge of the motorwell, it does not go all the way to the top of the transom.

Now, some builders cut it as #2 and # 3 and go all the way to the top. I don't find it necessary, it's heavy and may cost more in plywood but tecnically, there is nothing wrong with it.

You can proceed with what you have.

From the pictures, it looks like you have at least 12" below the upper edge of the motorwell.

Maybe I misunderstood your description: is it possible that you decided to have 2 transom layers and 2 clamping board layers for a total of 4? The design calls for 1 plus 3, total 4 but it perfectly valid to do 2+2.

In that case, you will have to cut a 3/8" slice off the motorwell sides but that is easy.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Dec 05, 2017 4:59 pm

by jacquesmm

About MarinEpoxy, many builders prefer a resin as clear as possible. When you mix, at first the mix will become opaque, after 60 seconds of mixing, it will become clear. Scrape the sides and bottom and be certain to mix enough. No opaque patches should be left in the mix.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Dec 05, 2017 5:10 pm

by peter-curacao

jacquesmm wrote: ↑Tue Dec 05, 2017 4:59 pm

About MarinEpoxy, many builders prefer a resin as clear as possible. When you mix, at first the mix will become opaque, after 60 seconds of mixing, it will become clear. Scrape the sides and bottom and be certain to mix enough. No opaque patches should be left in the mix.

I like it as clear as possible also, but maybe for silentneko a drop of brown pigment in the container of hardener is an idea? Or can you only mix pigment after you mix hardener and resin?

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Dec 05, 2017 5:47 pm

by jacquesmm

You can do that, good suggestion, thank you Peter.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 06, 2017 7:49 am

by silentneko

[/quote]I like it as clear as possible also, but maybe for silentneko a drop of brown pigment in the container of hardener is an idea? Or can you only mix pigment after you mix hardener and resin?

[/quote]

It would have to be a translucent tint which is harder to find, but really it's not a big deal. I just like the honey tone it gives to cedar. I'll try the resin on some scrap cedar I have, if it doesn't darken it enough I'll use some left over FGCI resin I have. Thanks.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 06, 2017 7:59 am

by silentneko

jacquesmm wrote: ↑Tue Dec 05, 2017 4:52 pm

Here is a drawing of the transom and clamping board (no perspective):

Number 1 is the transom outline, the outside layer, only one layer.

#2 is the designed clamping board, the one shown on the nesting. It has two horizontal straight edges spaced (in this case) 12". You had enough ply for 3 layers like that.

#3 is the the clamping board we discussed, the one that goes all the way to the bottom.

The upper edge of 2 and 3 is the edge of the motorwell, it does not go all the way to the top of the transom.

Now, some builders cut it as #2 and # 3 and go all the way to the top. I don't find it necessary, it's heavy and may cost more in plywood but tecnically, there is nothing wrong with it.

You can proceed with what you have.

From the pictures, it looks like you have at least 12" below the upper edge of the motorwell.

Maybe I misunderstood your description: is it possible that you decided to have 2 transom layers and 2 clamping board layers for a total of 4? The design calls for 1 plus 3, total 4 but it perfectly valid to do 2+2.

In that case, you will have to cut a 3/8" slice off the motorwell sides but that is easy.

Jaques, I don't want to get into a debate on the build thread, but the plans are in conflict with your description of the clamping board. The plans state to use the transom as a guide to trace out the CB layers, and the nesting diagram shows the layers going all the way up to the top of the full transom layer.

You are right, I am doing 2 layers of the full transom, and 2 layers of the clamping board. I feel this made for a much stronger transom, while only adding about 5lbs or so.

I did cut the top edge straight instead of adding a 2" radius. That's because I want my deck flush back there to accommodate a boarding ladder, or power pole micro, I might add. Thanks for the help, the transom is together now and I think it will work out well.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 06, 2017 9:38 am

by jacquesmm

You are correct, the plans show the clamping board going all the way up to the top of the transom.

Probably 100 boats were built that way.

Many use a small bracket and in that case, builders have simply built the transom from 4 layers, no clamping board layers.

We built a prototype here in the shop and I have to go back to check on how that clamping board was cut.

Either way is good. For larger boats, 50HP and up, I usually show a thick transom made from all the layers. For smaller boats, if the nesting is tight, only the clamping board has multiple layers and the shape of those clamping boards varies.

In this case, I was wrong about the shape.

To build it as you do, like the plans, allows for for boarding ladders, big U bolts and other fittings,

I will correct my previous posts and sorry for all the confusion.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 06, 2017 5:10 pm

by silentneko

It's all good. I think it's all worked out in the end now.

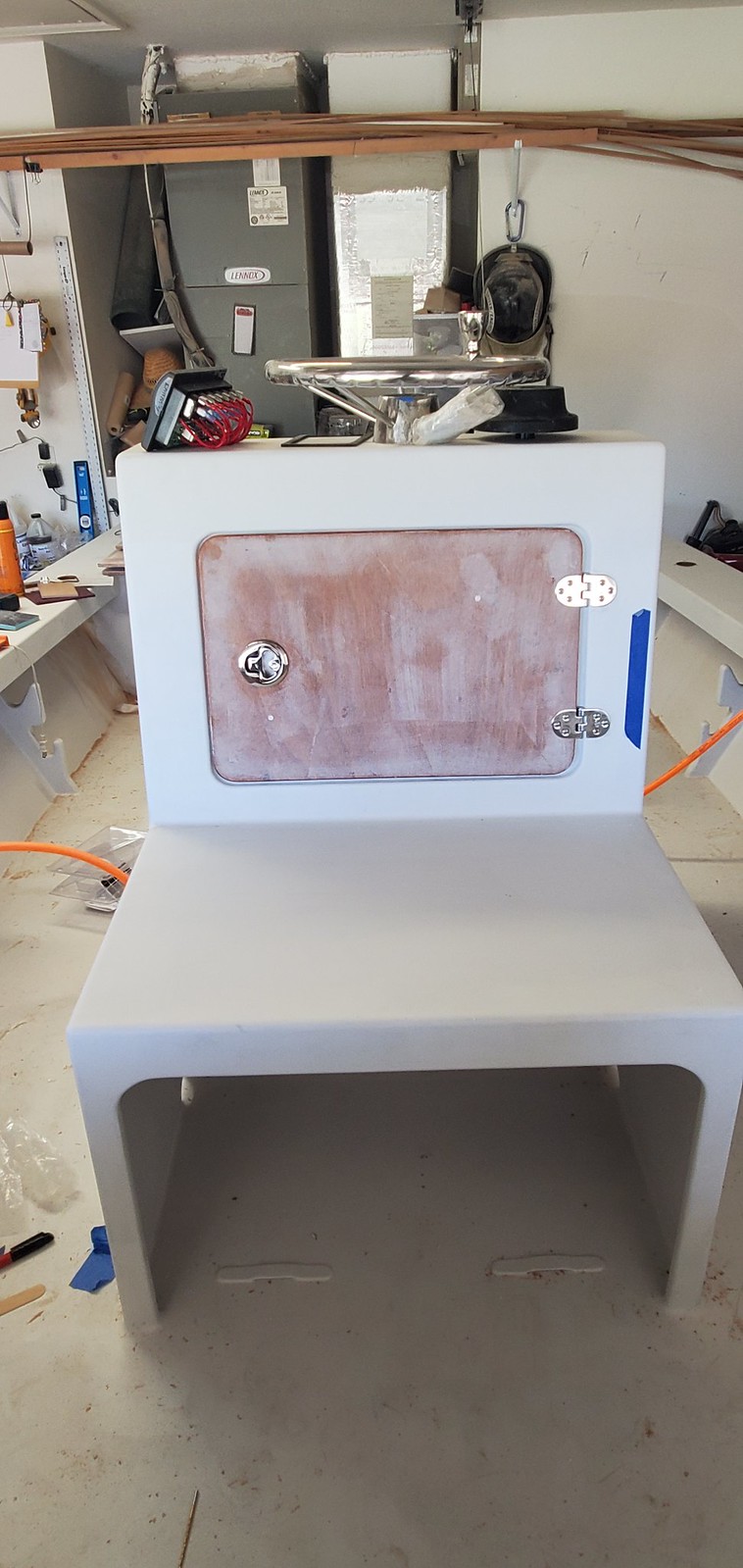

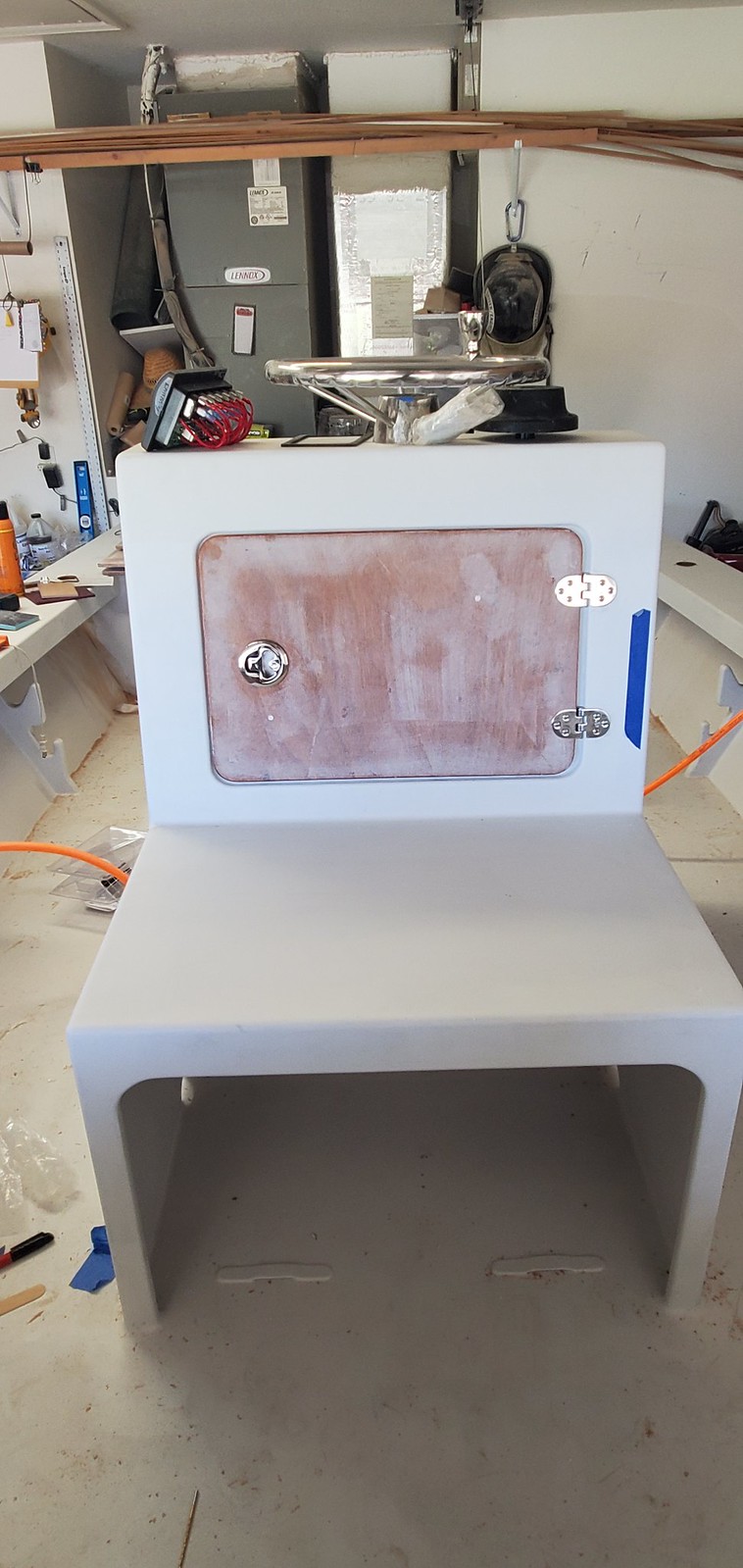

Here is the transom all laminated together. It's pretty stout and once the glass is added I'm sure this thing could handle any power I toss at it.

Here it is clamped in place. I can't imagine getting it more lined up, so I'm happy with it.

I then got the bottom panels cut out. Unfortunately I ran into a snag here, the plywood warped a bit. I couldn't line up the panel ends well, the best I could do is wet out the Biaxial cloth and weigh it down with a piece of MDF. It worked ok, but I'm not super happy with the results. It will allow me to do the other side well, then I may revisit it.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 06, 2017 5:28 pm

by cape man

Bet it will be fine when you flip it over.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 06, 2017 6:07 pm

by silentneko

We will see when I get a hard cure. It's flipped, I'm glassing the other side now.

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Dec 07, 2017 11:00 am

by silentneko

Well you can account for many things, but you can't stop mother nature. It's a wet cool day, but I'm gonna try and push on, just can't work outside of the garage.

I tossed the bottom panels up. Finally get to start seeing what will be. I've got a pinch point in the keel, I'll just need to smooth is out a little before final stitching.

The first side of glass didn't come out awesome, but it's not the worse either. I'll do an overcoat of neat epoxy to see it it can fill in a few small voids in the weave, if not I'll grind them out later.

I'm starting to bond the side panels together. I'll have to do it in multiple laminations because of the weather and space available.

I'm going to work on a few small projects just to get ready soon, like the drain tube and rounded live well ends in the next few days.

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Dec 07, 2017 3:22 pm

by silentneko

I ran out soon after my last post because I got a email about a sale at Lowes. A little while later I ended up with a new toy for $49

This resin is much slower then I figured so I have to wait a bit longer. I got the medium hardener, it gives me about 12-15 minutes work time, but takes about 6-7 hours to harden. It's been between 72-81 degrees this week so far. I'm glad I didn't option for the slow hardener, but I think the fast might have to little work time so the medium will work out fine.

Since I have some extra time between the resin drying I tackled a small project. Let me start by saying I hate brass drain tubes. I had one on my old gheenoe and it always leaked. I get why they exist, but since we put so much time into our boats why not make a better drain tube? I've done this on my last few boats and it works out great with no chance of leaking around the tube.

I start with a 1" dowel, then sand about 1\16" off so the plug fits well, and because wrapping it in plastic adds thickness back.

Wrapped in plastic, I only need about a 1.5" section so I make one 4" long with room to trim.

I wrapped the glass around and secured with some tape. I used scraps I had around. I think I ended up with 2 layers of veil cloth, and 3 layers of 9oz cloth.

I wet it out with tinted resin. Since my boat will be ice blue I tried to match it using white and blue tint. Make sure to apply the resin and roll it out the same direction you wrapped it.

Once it's cured and I'm ready for it I will drill an oversize hole and bed it with thickened epoxy. I'll leave at least 1/8" hanging out and sand it flush once cured.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Dec 08, 2017 1:20 pm

by silentneko

While working on the panels I took some left over resin and applied it to me test pieces. Eventually these may become rod holders and the structure for the leaning post and platform. My concerns about the resin not adding enough depth of color are not as bad as I thought. The curved beam I wish was a bit darker though, but I might just go with it and use some golden varnish on top. I'm not sure if you can tell, but the beam is made of 4 layers, the final product will be at least twice as thick.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Dec 08, 2017 2:58 pm

by silentneko

So a moment of triumph has been replaced with.... sometjing else? lol.

I was finishing up bonding the side panels together and noticed things looked a little askew. I pushed on cause it looked close enough. Then I decoded to stitch the hull bottom together as a test fit. Heres where I'm at.

As you can see it's not even close,and this is after I took down the sharp edge that was binding. I rechecked the measurements and everything seems right, But the panels hand off the transom at an angle. I checked the transom and it's square to the frames. I restitched 3 times leaving them loose as can be, even using dowels under the ties to align them. Then I checked out the boards and here is where I found the issue, the sheets of plywood are not square. I checked out some of my remaining sheets and they are slightly off square, and the 8ft side has a dip in it about 1/8". This could be from sitting around my garage while I compiled my errors on the strong back, but they should still be square I would think. Not sure where to go now, knowing the side panels will be off too.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Dec 08, 2017 3:47 pm

by narfi

Your panels look symmetrical....

Can you hang your side panels on and see how it looks?

I would think if they look good, then you could grind a little down on the points touching and fill a little extra in the gaps without any real issues?

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Dec 08, 2017 3:57 pm

by silentneko

They are symmetrical, but the butted joints are just a bit off square. So I squeeze one end and it's way off on the other. Upwards of 3/4". I can reshape them by hand, but then they won't match the framing cause I'll have to grind away a lot. I guess I can just fill it all in with thickened epoxy? Not thrilled about that option though.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Dec 08, 2017 4:23 pm

by jacquesmm

Looking at your previous picture with the panels flat on the ground, the picture with the jugs on the tape splice, I see a flat line along the keel side curve.

That is probably a large part of the gap.

IMHO this is an acceptable gap. I would keep going.

Do not worry about the panels fitting perfectly on the frames. That will happen especially close to the bow. The frames will support the panel but at this point we car mostly about fairness.

Another point to pay attention to is the droopy bow. Pull the tip of the bow back with a line or use a bow mold.

I think I see a bow mold, not certain.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Dec 08, 2017 4:35 pm

by Jeff

Build on Silentneko!!!! Jeff

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Dec 08, 2017 4:36 pm

by silentneko

It looks flat, but it's a subtle curve there. The issue starts further back at the joint of the 2 panels. I can knock down the point a bit more and fit it better. Is it OK to fill in a large gap with epoxy thickened with wood flour and milled fibers? Or will it create an issue later on?

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Dec 08, 2017 4:58 pm

by Jaysen

I may be slower than a box of rocks covered in molasses sitting on Fuzz’s door step, but I don’t see the problem there. Is it the gap?

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Dec 08, 2017 5:13 pm

by silentneko

Yes, it's quite a bit more then the 1/4" typically deemed acceptable. It also goes down most of the keel. I can make it work, but it's going to take a significant more amount of resin and filler. I'll have to get some backing under it so it doesn't just fall through. I'm formulating a plan here, lol.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Dec 08, 2017 7:28 pm

by Jaysen

Packing tape. Stitch it all together and use some tape on one side to prevent fall out. Use wood scraps to fill really wide spots and then thickened epoxy like normal.

If that didn’t work, quite a number of these boats wouldn’t be floating.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Dec 09, 2017 11:12 am

by jacquesmm

Yes it is more than most gaps but it is not a big deal.

If you think that you can solve the problem by trimming the spots where the panels push against each other, do it.

If not, later when you fiberglass the inside, add a layer or two of biaxial tape along that seam, over the gap.

Also, things may even out when you add the side panel.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Dec 09, 2017 2:23 pm

by silentneko

I think I'll end up doing both. Reshape a bit, and add some extra cloth on the inside. This is the major hump, once I get past this basic shaping the rest of the build I know will be more fun. I'm even looking forward to fairing to a good work boat finish.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Dec 10, 2017 4:32 pm

by silentneko

I was working on the bottom panels, trying to figure out how to correct the issues and realized I have a decent amount of rocker in the transom. Well over 1/8", I can't use the stringers for help because they sit near 3/16" proud on top of that. I tried using a straight edge, but somehow ended up back the same.

I've got a plan to realign the center, but can't proceed until I get this solved. If not my hull bottom will end up being more filler and fairing compound then wood. I haven't even tried the side panels yet as I know they are out of square too. I don't have the stringers in the jig because they are so far off they won't let the bottom panels lay fair. Lol I just need one thing to go right before I snap.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Dec 10, 2017 4:59 pm

by jacquesmm

Rocker on the transom? Rocker is longitudinal, I suppose you mean rocker as I show in some of my HowTo files.

1/8 may not be enough.

In the PH16 and PH18, designed 25 tears ago, I put 1/2" of rocker in the plywood.

I don't discuss it often but have said it a couple of times over the years. I put a tiny little bit of rocker in the plywood close to the transom because you will be piling up layer of glass there with the transom fiberglass overlaps, at least 1/8". If it was flat, you would create a hog, the opposite of rocker,

To have a little of rocker there is perfect, it is intentional.

What I did not expect is for people to worry about that 1/8" at the plywood stage.

It is fine, keep going.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Dec 11, 2017 6:35 am

by silentneko

Lol, bet you didn't expect to sell a lot of plans to guys with a touch of OCD. Ok, I'll keep going.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Dec 11, 2017 11:23 am

by jacquesmm

I am the opposite: very optimistic about gaps. I always think in terms of fiberglass boatbuilding.

The plywood is nice core that provides stiffness and add strength but in a large boat, most of the strength comes from the glass,

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Dec 11, 2017 12:32 pm

by silentneko

I don't mind if it was a slightly bigger gap in just one area, but the more I dig in the worse it's getting. I've never had so much trouble with any of my previous builds. I bundled up and spent 3 hours freezing this morning trying to figure this out. I installed blocks to secure it in place so I can re scribe the panel, well actually seeing the panel curved showed it was worse then thought.

The major issue isn't what I did, it's that the factory edge on the 1/4" sheet is off nearly a degree. It might be hard to see but here is the gap at the transom. I might have no choice, but to live with. This is with the centerline factory edge lined up, and yes it is symmetrical on both panels.

It's so far off that the bow mold isn't even touching anymore. If I cut it back further so it fits up front the gaps along all the other edges and centerline become more severe. again the problem is the factory edge is off, so If I line up one side of the splice the other is way off. The only solution I can even think of at this point would be to cut the splice apart and reangle it, but I can see that ending up in disaster.

I feel like I've done a lot of complaining thus far and it bothers me because this isn't typical for me. My 3 other builds have been very positive and I apologize to the members here for that, but I'm not sure how to proceed mentally from here after so many hours with no progress.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Dec 11, 2017 12:50 pm

by narfi

I think I might see the problem....

- fs17_panels.jpg (304.19 KiB) Viewed 1425 times

The plans show the center-line straight from the transom to where the curve starts.

Perhaps it is a trick of the camera, but both of those pictures show a 'lump' sticking out which I could see causing the issues you are having.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Dec 11, 2017 2:50 pm

by silentneko

The panels were supposed to be straight like you discribed, the point is where my curve originated and needed to be smoothed out. Since the panels weren't quite square they curved back towards the center.

I'm working it out. Ready to bang my head against the wall some more, but getting somewhere, maybe. The scary part is I haven't been able to even see how far off the side panels are yet.

So I come in cussing a bit and try telling my wife what's up. She says "you have a good budget, why don't you just go buy a boat and fix it up instead?".......... My response "Damned it Lisa! That's not the point!"

Come Hell or Low water I gotta find a way to make this thing float.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Dec 11, 2017 5:06 pm

by Jaysen

silentneko wrote: ↑Mon Dec 11, 2017 2:50 pm

I gotta find a way to make this thing float.

Water will float it.

Don't stress about creating gaps. Just about everything you describe (unless I'm missing something, and I usually am) can be "cut and stretched" with the S&G method used to build these boats. Seriously. If gaps were an issue, Lil Bit would have sunk the first time she got wet. The entire bow is epoxy and filler.

I'd recommend doing what JM said. Loose stitches and get to the point of putting the sides on. Don't worry about transom yet. See how it lines up and determine the action that will get you back on track.

Zip ties are cheap

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Dec 11, 2017 5:45 pm

by silentneko

Well it's a Holiday season miracle! I think I actually figured something out here.

After 8+ hours of measuring, screwing, unscrewing, zip tying, cutting zip ties, measuring again, leveling, setting up laser, stitching panels again, scribing, cutting, trimming, sanding, sweating, and bleeding, I think I have it mostly resolved.

I re mounted the transom where I'm happy with it. Then I took one of the panels and blocked/clamped it in place. Well as close to its place as I could get. I took the laser and set it up on the center line of the jig. The sharpie lines you see are where the laser hit, and go all the way almost to the transom. Reason being I decided I would rather have the gaps on the chine then the keel.

I trimmed and sanded the panels and stitched them back together. They fit well enough, but need some more sanding due to rubbing on the edges. I'll have gaps to fill on the chines and transom edge. It's a good thing I doubled the transom thickness, or part of the bottom panel would be floating in the air.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Dec 11, 2017 6:00 pm

by narfi

That looks great!

I am glad you figured it out.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Dec 11, 2017 7:46 pm

by Jeff

Mice work Sikentneko!!! Looks really good!! Jeff

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Dec 11, 2017 8:18 pm

by silentneko

Thanks guys. I tossed on the side panels. I lucked out a bit here because I turned the panels around, the edge that was off kinda canceled out. The sides don't fit to bad, I'll need to make some adjustments though. The boat is a lot bigger now, lol.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Dec 11, 2017 10:40 pm

by TomW1

Loosen up your ties at the bow between the bottom and the side, you don't have much gap there. This will let the sides drop down a little and you can reduce the gap between the sides where there is a larger gap near the bottom.

Tom

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Dec 11, 2017 11:25 pm

by Fuzz

I am sure there is a little fine tuning you can do but it looks good from here. After all the fight you have had I think you are just about ready to glass that puppy

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Dec 12, 2017 6:13 am

by silentneko

The way it's stitched together is just to see how it lined up and if the sides needed to be cut back. I'm going to take it all apart again and do just a little fine tuning before I finalize it and start bonding everything. It's been a unusually long road to this point, but once over this humpage things will smooth out I think.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Dec 12, 2017 7:44 am

by Jeff

Good stuff Silentneko!! You are now on your way!! Jeff

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Dec 12, 2017 11:59 am

by jacquesmm

It looks really good, keep going.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Dec 17, 2017 12:17 pm

by silentneko

Spent a few days here and there trying to line up the panels a bit better. I've got gaps and some spots that bind a bit, but I decided it's good enough.

I bonded the transom in then I spot welded/epoxied the joints. I started removing zip ties and it began shifting a bit, so I went back and added some more spot welds.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Dec 17, 2017 12:29 pm

by cape man

Looking good!

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Dec 17, 2017 2:46 pm

by jacquesmm

Yes, it looks very fair and smooth.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Dec 17, 2017 3:56 pm

by TomW1

You can't get much better than what you have so build on.

Tom

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 20, 2017 4:39 pm

by silentneko

Everything is stable and bonded, so I removed the zip ties and prepared to lay down a bunch of thickened epoxy. You can see how there is a gap in the edge of the transom, I'll have to fill this in along with all the gaps on the sides.

I sanded the hardened spots lightly cause I was over the 72 hour window. Then did 2 passes with thickened epoxy, first just to get a base to build on, and will likely do a third after I sand it to see how even it came out. I also filled the zip tie holes.

Now I know some will say not to bother filling the edges in as much as I am, but I really had to. Because of the alignment issues I had earlier my gaps were uneven to the point that without this step it would be hard to find a registration point to make it all have an even radius.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 20, 2017 7:04 pm

by Jeff

Silentneko, looking really good!! Nice progressand happy holidays!! Jeff

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Dec 21, 2017 5:20 am

by cape man

Good call on getting it so your radius is true. Looks great.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Dec 26, 2017 4:41 pm

by silentneko

Nothing dramatic to share due to the holidays. I did get out and continue squaring up the corners. It should be ready for shaping when it's cured.

A quick sanding to knock down the high points and then more thickened epoxy applied.

Here you can see I really had to bridge some wide and uneven gaps, but I think the end result is pretty well fared.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Dec 26, 2017 6:58 pm

by Jeff

Good progress Silentneko!!! Happy holidays, Jeff

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 27, 2017 1:51 am

by Fuzz

That is some good looking work. And those gaps are nothing, remember gaps are good.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 27, 2017 2:26 am

by narfi

I understand filling the gaps beyond what is needed to sand down to the radius for taping, but what is the benefit of squaring it off first?

How do you plan on doing the radius? Freehand sanding or something fancier?

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 27, 2017 10:17 am

by jacquesmm

narfi wrote: ↑Wed Dec 27, 2017 2:26 am

I understand filling the gaps beyond what is needed to sand down to the radius for taping, but what is the benefit of squaring it off first?

How do you plan on doing the radius? Freehand sanding or something fancier?

At this point of the building, the edges should be round with a radius of about 3/8".

The reason is that you can't fiberglass over a sharp corener without creating air bubbles, that edge must be round.

Some builders like to make it straight first then grind the edge down. They do that to ensure a nice fair chine.

Later, after the fiberglass, the builder can rebuild a sharp edge but I would not bother. It is only important at high speed. Look at the edges of production boats, they are not sharper than about 1/4" radius.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 27, 2017 11:14 am

by silentneko

narfi wrote: ↑Wed Dec 27, 2017 2:26 am

I understand filling the gaps beyond what is needed to sand down to the radius for taping, but what is the benefit of squaring it off first?

How do you plan on doing the radius? Freehand sanding or something fancier?

Thanks guys.

Jacques pretty much summed it up. Because my gaps were uneven I took the time to square up all the edges. If I didn't do this step I would have a wavy chine edge that would require a lot of fairing work on the back end. This way it's straight and strong.

I'll be knocking it all down to a 3/8-1/2" radius. I think the only way to do it is really free hand, because the angle of the edge changes with each inch, especially towards the bow. I might make a little guide piece to check the radiscussion every so often, but you should be able to feel and eyeball it most of the way.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 27, 2017 12:50 pm

by poleposition

[/quote]

ll be knocking it all down to a 3/8-1/2" radius. I think the only way to do it is really free hand, because the angle of the edge changes with each inch, especially towards the bow. I might make a little guide piece to check the radiscussion every so often, but you should be able to feel and eyeball it most of the way.

[/quote]

I know several builders have used a brick jointer to form their radii, like this one @ Amazon:

https://www.amazon.com/MARSHALLTOWN-Pre ... GKSJYX2ZMA

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Dec 27, 2017 1:04 pm

by silentneko

I can see that useful for inside corner fillets, but how would you use it as a Guage on an outside edge?

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Dec 28, 2017 2:54 pm

by TomW1

After you rebuild your edges up take time to round them over just a little 1/32 to 1/16 so that paint will adhere. Paint doesn't like to adhere to a sharp edge.

Tom

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Dec 28, 2017 4:16 pm

by silentneko

Tom the sharpened edge isn't for painting, it will be radiused. I gave a better explanation a few posts ago.

I got a few hours in today rounding the edges and fixing a few small things.

Someone asked how I planned to make the radius. I made a small guide by boring a hole in a scrap of MDF, then made some slices so the are different sizes to use on different angles along the chine.

Sand a bit and slide it along the edge to see if you need to sand more in a spot. Don't be super aggressive, I used 80 grit and took my time.

She's about ready for some glass. This is the same radius I on my last boat, but used it with heavier 17oz biaxial. I filled in some pin holes and gouges in the wood, so it's as good as it gets.

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Dec 28, 2017 4:33 pm

by Jeff

silentneko, Looking really good!! Jeff

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Dec 28, 2017 5:23 pm

by OrangeQuest

Very well though out and inventive too. Looking good.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Dec 29, 2017 6:38 am

by topwater

Looks good glass it

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Dec 30, 2017 9:31 am

by silentneko

Well we have a house full of sickness, but I managed to get out and do some work. The temps only got up to the low 60's.

Biaxial tape cut and staged.

Then glassed.

if you noticed I have a heat gun hanging from the garage door opener. This is essentially my ghetto heater. I suspended it away from everything and plugged it into a gfi outlet. I just use the low setting, but that's enough to keep the garage at 70-71 degrees with the door closed. Not a perfect solution, but it's safe and keeps me from buying another one time use item.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Dec 30, 2017 10:16 am

by OrangeQuest

Your build is looking great!!

Heat gun....love tools that multi-task!

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Dec 30, 2017 11:44 am

by Jeff

Nice clean tape work!! Like the idea of using your heat gun to keep warm stable temp!! Hope the family gets better!! Happy New Year!! Jeff

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Dec 30, 2017 6:48 pm

by Aripeka Angler

That's a nice looking job on your taping.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 03, 2018 10:33 am

by silentneko

Thanks guys.

Not much to report, still a bit sick, but it's wet and cold as you all know so I'm not going to open the garage door just yet.

I did however get around to ordering some HBN (white graphite) to do the epoxy graphite coating later on. It's pricy stuff, and even though I still had some black graphite left I didn't feel it would look right on this build.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 10, 2018 4:17 pm

by silentneko

Not much to report. The weather has been pretty bad, just wet and cold, so not much has been done. The problem with building in a small garage is I have to open the door to access the front of the hull. I did get around to sanding the tape down, it's ready for the rest of the fiberglass.

After sanding I applied some neat epoxy over everything. I know it's not needed but I like to fill as many of the small voids as possible. The biaxial has a very wide pattern compared to woven cloth, this will held bonding to the next layer of glass. I'll give it a quick sanding before applying the final biaxial in a few days.

It was cool out today, so after applying the resin I used my happy little heat gun to warm up the garage. Went from 70 degrees up to 81 in about 20 minutes.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 10, 2018 4:19 pm

by Jeff

Looks really good!! Jeff

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 10, 2018 4:42 pm

by TomW1

Looking good guy. Tom

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Jan 12, 2018 4:21 pm

by silentneko

The weather has been crappy lately, but I'm pushing on. I gotta say, biaxial adds some challenges, it's just not as fun to glass as woven and a pain to fair, but I understand it's purpose. That being said it seems to take longer to wet out then cloth does, so I was only able to do half the hull today. I hope to find some time tomorrow to finish, but I'll have to sand the edges again.

Half primed

Half glassed

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Jan 12, 2018 4:32 pm

by Fuzz

Fine looking half glass job

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Jan 12, 2018 4:47 pm

by silentneko

To be honest, it's not my best work.

So I have a tip for those of you ordering a large quantity of glass. Either have a helper available when rolling and folding the glass for measuring, or maybe have them split the roll into 2 to make it manageable. The roll of glass is 50 inches wide and weighed like 30+lbs, so it's very awkward for a guy running solo in a cramped garage to move around. I ended up with a bunch of pulls and snags. Not a big deal, but it means some more sanding and touching up later on.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Jan 12, 2018 7:41 pm

by Jeff

Maybe so Silentneko, but still nice job!!! Jeff

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Jan 13, 2018 8:50 am

by topwater

Glass job looks good. How are you putting the epoxy on the glass

Just pour it out and move it around with a spreader and a

roller.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Jan 13, 2018 10:18 am

by silentneko

Thanks. I prefer to roll it on a little at a time. I find its wastes less epoxy and I end up with less bubbles. It does take longer this way. Then I roll over it with a glass roller to get rid of as many bubbles as possible. Your still going to have some as biaxial is course and wide compared to woven. Never been a fan of brushes or squeegees.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Jan 13, 2018 10:40 am

by Bogieman

She is coming along nice. Your glass work looks really clean.

Bogie

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Jan 13, 2018 11:17 am

by silentneko

Thanks, I'm trying to only show the good stuff right now, lol.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Jan 15, 2018 1:45 pm

by silentneko

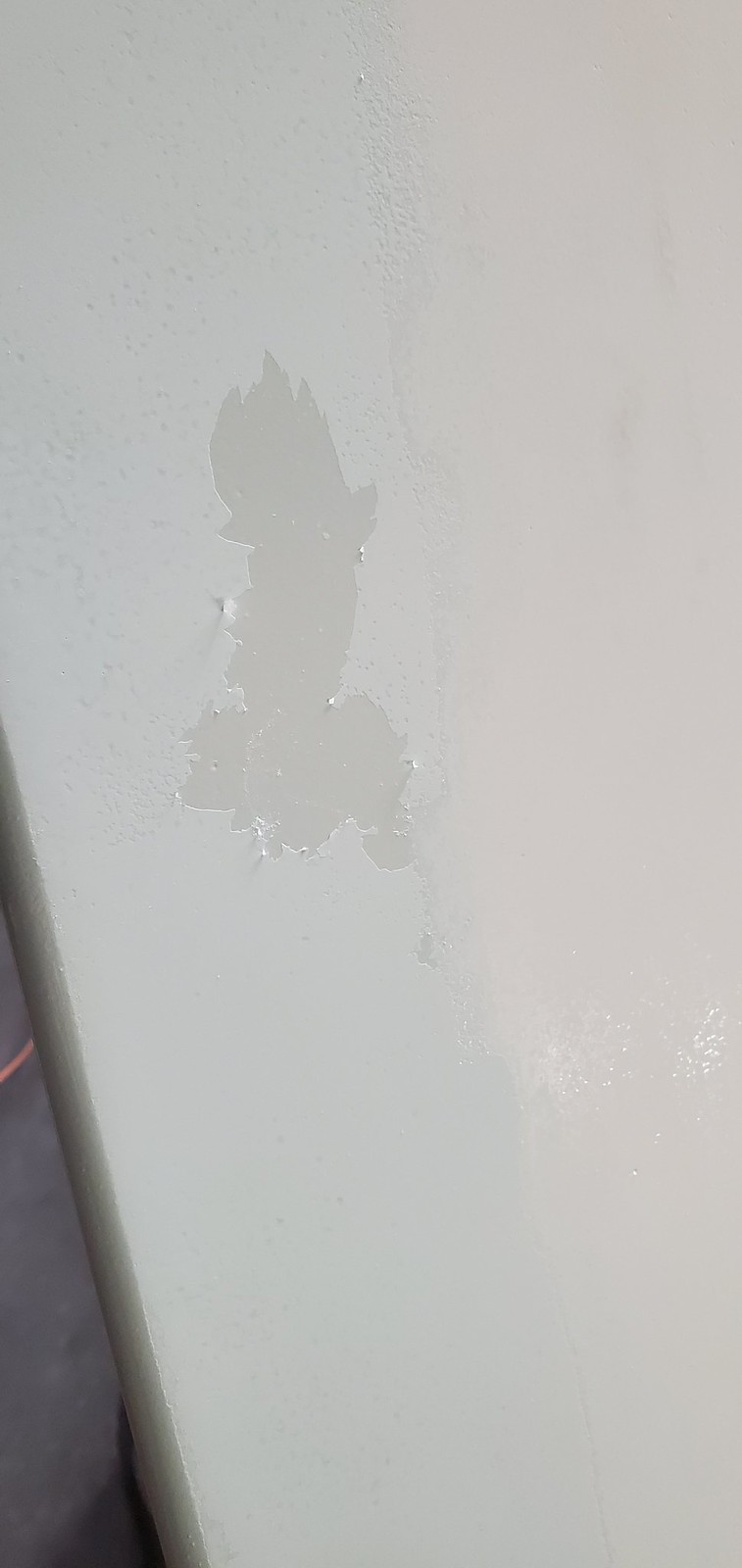

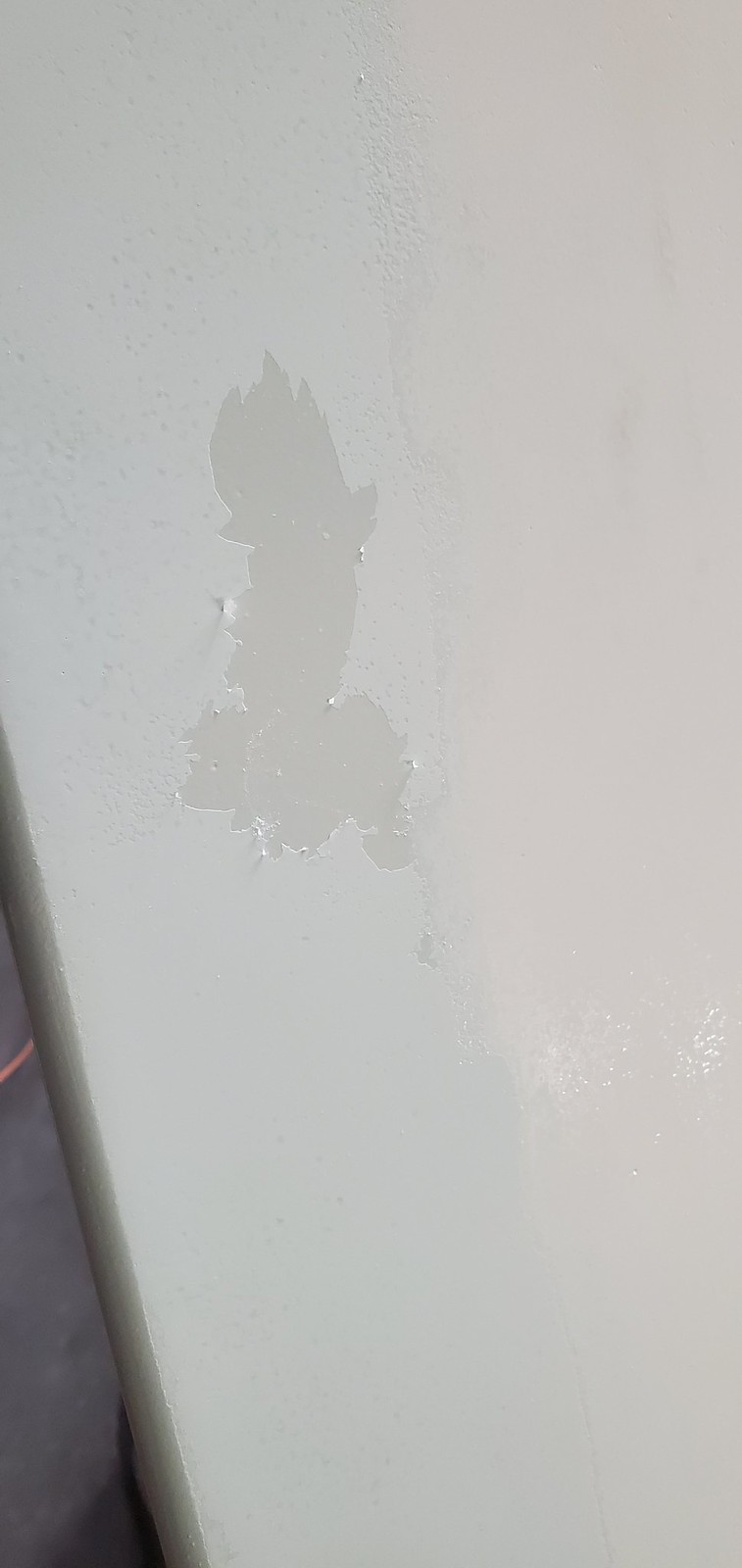

Ok so I'll show a little of the not so pretty stuff. Enough pictures of perfectly laid glass, here's some patch jobs I'm doing. According to the plans I only need glass 6" up the sides, well I don't agree with that cause just resin coating can lead to having the wood check later on so I prefer a light cloth to stabilize it. Nearly every inch of my boat will be glassed. That being said, you can see where the biaxial laid after glassing leaving a few areas that have no glass.

I sanded the edges to everything, then used some scrap 6oz glass cloth I have to cover the remaining areas.

After finished I epoxy primed the other side of the hull. I'll let it set up for a few hours then go put the rest of the biaxial on.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Jan 15, 2018 2:13 pm

by jacquesmm

Checking happens with cheap plywood, not with Okume or Meranti, Epoxy coating is sufficient but maybe half the builders prefer to cover the whole outside with glass and I don't see any problem with it.

For larger boats I specify outside glass all the way up the sheer.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Jan 15, 2018 2:26 pm

by silentneko

Jacques, the Okoume I got from here is already showing minor signs of checking, and the meranti I got last time checked in a few spots too. Maybe I just have bad luck.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Jan 15, 2018 2:37 pm

by jacquesmm

It's difficult to tell from a picture but it's OK to fiberglass all the way up to the sheer. It will also offer some protection against scratches.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Jan 15, 2018 4:34 pm

by narfi

silentneko wrote: ↑Mon Jan 15, 2018 2:26 pm

Jacques, the Okoume I got from here is already showing minor signs of checking

I see that on some of mine as well, but I think Jacques is right that epoxy would be enough to stop that, however I also plan to finish up the sides with 6oz.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Jan 15, 2018 4:39 pm

by silentneko

That's a gamble I'm not willing to make. If you just seal it in epoxy and it still checks that means you now have to grind off all the paint, primer, fairing material, and then reglass it all so it doesn't happen again. All to save $30-50 in material. Plus with my luck and as much trouble as I'm having with this build, that's exactly what would happen.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Jan 15, 2018 6:59 pm

by Aripeka Angler

Nice looking glass and epoxy work Neko! I like your plan to fully glass the hull.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Jan 15, 2018 9:10 pm

by Fuzz

I too would glass it all the way to the top. I do not like scabbing a piece in so the next boat I build will have one piece of glass over the whole side. This will leave extra glass but I would carry it over the chine about 6 inches or so. I would end up with an extra layer over the chine but that being a high wear spot makes it a good thing to me.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Jan 16, 2018 9:39 am

by silentneko

Hindsight being 20/20 I think I'd sheet the whole bottom and sides in a layer of 6oz. It would cut fairing time in half and not add to much weight.

I thought I ruined a run of biaxial by having to roll and unroll it several times, but I think it will work still. I spent over an hour unrolling and straightening the cloth out. Next build I'll have several extra cardboard tube around to roll up glass after measuring it out.

I'm waiting for it to warm up a bit until I go and wet it out.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Jan 16, 2018 11:29 am

by jacquesmm

Do you mean adding a layer of 6 oz. over the biaxial? That is OK but you can't substitute the biaxial with 6 oz.

Professionals use what we call a veil over biaxial: a thin layer of woven cloth like our 3.25 oz, fine weave, to cover the pattern of the biaxial.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Jan 16, 2018 2:39 pm

by silentneko

Yes, I mean over coating the biaxial with 6oz woven. I'm not going to do the math, but I bet adding a layer of 4 or 6oz glass then fairing would weigh close to adding all the fairing compound needed to smooth out biaxial.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Jan 16, 2018 4:49 pm

by remedy32

When I built my FS17 I had the same issue with just how rough biax comes out, especially the stitches. After doing the chines, keel line and all bulkhead bonding with 12oz biax, I decided to do the bottom itself with 2 layers of 7.5oz woven; one layer fore-aft and the other at a 45deg bias. It's held up just fine and did not require too much fairing material to get it smooth. I ran a single layer to the plan sheerline. I did not glass the 8" sheer bulwark extension and I wish I had. It's Hydrotek Meranti BS1088, epoxy coated, primed and finished in 2 part urethane. It's the only area of the boat with any checking; just fine lines and purely cosmetic but irritating. Boat is going to get a well earned 9 year cosmetic rehab this spring so that will probably be on my list.

I'll glass all the plywood in future like others have said.

Bill

CT

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 17, 2018 4:55 pm

by silentneko

I'm glad I did it, 6oz glass barely weighs more then a few neat coats so its worth it to me.

Ok so I finished glassing the outside, but if anyone is following the gel issues thread you know I'm having a bubble issue. I'll work that out with the help of a Drexel soon.

Now I have some choices to make on the reverse chines. I need to decide when to bond them and the strakes. I don't like the idea of them bonded to fairing compound, but fairing first is easier since they aren't in the way. If I bond them now it will be stronger, but later will be easier...... decisions....

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 17, 2018 5:39 pm

by narfi

My thought was do an initial sanding to get knock the lumps and thread off the glass then install the chines and strakes. Fairing will be a little more difficult, but it will be a strong bond this way, and the fairing is more important on the sides than the bottom where no one sees and is covered by thick coats of graphite/epoxy.

I am open to having my mind changed though

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 17, 2018 9:31 pm

by silentneko

No need from my end, as that's the direction I'll most likely be going.

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Jan 18, 2018 5:51 pm

by silentneko

So I'm done glassing the bottom, I have a few spots to fix but nothing major. I do have a little bit of a droopy transom, I'll check it over in the next few days and I may need to add a small layer towards the back foot or so to bring it up a bit. Not a big deal.

So I'm working on figuring out my reverse chine shapes and angles. The biggest issue is the changing angle at the chines. I think I have it figured out though. I'll mount them, then use a small amount of fillet material to fill the gap so the hull side angle is consistent. Here were the first few I tried. 1" tall and 3/4" tall x 1.5" wide. Not bad but, I don't think they fit right.

I then tried 3/4" tall by 2" wide, and I think this looks much better. I believe this would be plenty to deflect any spray under normal runs, anything nasty enough to get past these I'm probably getting wet anyways right, lol.

I plan to start then a few feet back from the bow and run them to the rear. I need to decide what wood to build them out of. It needs to be flexible enough to make the curve, and also solid enough to not crack when I drill holes to keep it in place. I'd rather stay away from pine, and hard woods won't make the curve easy, so I'm thinking I'll just use some cedar.

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Jan 18, 2018 5:57 pm

by Fuzz

I agree the last shape looks much better. Might even want to try one a little flatter and see how you like that.

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Jan 18, 2018 6:07 pm

by silentneko

Once I round over the top it will look more pleasing to the eye I think.

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Jan 18, 2018 7:01 pm

by narfi

How does it look with the square corner against the chine?

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Jan 18, 2018 8:43 pm

by silentneko

Not as good, and I'd end up shaving off a lot of the height to get it smooth with the sides.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Jan 19, 2018 4:56 pm

by silentneko

It's getting time to start a ton of sanding, and I'm already itchy. I have an old shop vac, and an old orbital sander......why not duct tape them together? Well Gorilla tape at least and a few zip ties.

Seems to work pretty good and should greatly cut down on the dust.

I also fixed up most of the air bubbles I had. I ground them out with a dremel bit, then went over them with a mix of epoxy and milled fibers.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Jan 20, 2018 1:12 am

by Fuzz

Not sure how flexible your hose is but there is an orange hose for that vac that is pretty flexible. It might make things work a little easier for you. Anything you do to catch the dust from the start will be a big help.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Jan 20, 2018 7:33 am

by Browndog

My sanders just blow dust everywhere. I do a lot of vacuuming after the fact. Every so often, I open the garage door and use the leaf blower to blow it away on to the gravel driveway. Sanding is my least favorite part of boat building. Have at it. Use whatever you can that makes dust reduction/collection easier. Always use a mask or respirator if you got one.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Jan 20, 2018 8:18 am

by Noles309

silentneko wrote: ↑Fri Jan 19, 2018 4:56 pm

It's getting time to start a ton of sanding, and I'm already itchy. I have an old shop vac, and an old orbital sander......why not duct tape them together? Well Gorilla tape at least and a few zip ties.

Seems to work pretty good and should greatly cut down on the dust.

I did the same exact thing. It really makes a huge difference.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Jan 22, 2018 8:55 pm

by silentneko

So the good news is duct taping the shop vac to the sander seems to work really well. I sanded for section tonight and there was barely any dust. I would say it reduced the dust by at least 2/3's. Bad news is my sander is on it's last leg, I'll need to replace it before the marathon of sanding ahead.

I was able to get out today and get some more resin so I should be good to go this week. After sanding I'll need to build up the last foot or so near the transom to get rid of the slight rocker it has.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Jan 23, 2018 3:30 pm

by silentneko

The 5" orbital sander of my dreams....

Was going to get another dewalt, but looked into it and went with the ridgid. 3 amps, variable speed, connection ready for the shop vac, and a Lifetime warranty! (As long as it's registered, and it is). It was the same price as the basic dewalt, $59.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Jan 23, 2018 5:03 pm

by Pat4

Sanding time

The most essential and the same time worst thing of boatbuilding

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Jan 23, 2018 6:06 pm

by silentneko

No doubt. That's why I like the term "work boat finish". I might just fair the bottom with the orbital, and hand block the sides a bit. I'll be covering the bottom with Epoxy/HBN anyway so it doesn't need to be perfect.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Jan 23, 2018 8:06 pm

by Jaysen

I like Fuzz's view on finishes...

Fuzz wrote:30 feet at 30mph

That's my new motto.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Jan 23, 2018 8:34 pm

by Fuzz

I have to like a 30-30 finish, that is the best my talent level will produce

I am just amazed at the finish some of these guys can do.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 24, 2018 2:34 pm

by silentneko

Some of them are really nice, some are internet magic. What looks good in pictures might not be that perfect up close, so don't doubt yourself, side by side I'm sure your work will stand up to most.

So, sanding.......yep! I spent about 3 hours today doing the first pass of sanding. I also trimmed the excess glass that was hanging off the sides with a multi tool. I decided not to be to aggressive, I've seen some guys sand until the whole boat is milky white. Problem is they are cutting into the structural glass, I just wanted to take down the high spots and some stitches.

Once I was done with sanding the hull, I blew off all the dust carefully to see what I had. Because of the bubble issue from before I had a lot of little spots that I needed to check. I took an awl and a stainless wire brush, and I pushed on every single spot I could find that didn't look perfect. If it moved I chipped it out and cleaned it up with the brush. This worked great and took about 30 minutes. None of it was structural, but could have given me issues later on when fairing and painting.

I think I'm going to do a thin overcoat of neat epoxy to seal any edges I exposed and get ready for chines, rubrails, and fairing.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 24, 2018 4:40 pm

by Jeff

Really nice silentneko!!! Jeff

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 24, 2018 5:08 pm

by Browndog

Looking good!

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 24, 2018 5:40 pm

by silentneko

Thanks guys.

I bought a new table saw so I can do the reverse chines. It's funny cause in the thread I started on them the guys are trying to get me to go bigger, but on another forum I'm on the guys with experience are telling me to go smaller. One recently finished building a strip boat that's not to far off from this one. He sent me a video of his reverse chines working decent, so I'll play a bit more and try a few more profiles. I do hope to at least start them or the rub rails within a week, cause I'll have to take a few days off coming up.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 24, 2018 5:53 pm

by Fuzz

Glass job looks really good.

As for the chines my thought is there are lots of opinions out there. If it were me I would give the most weight to any who have built and/or running a FS-17. There have been a number of them built so hopefully some of those guys will weigh in here.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 24, 2018 8:29 pm

by jacquesmm

Fuzz wrote: ↑Wed Jan 24, 2018 5:53 pm

Glass job looks really good.

As for the chines my thought is there are lots of opinions out there. If it were me I would give the most weight to any who have built and/or running a FS-17. There have been a number of them built so hopefully some of those guys will weigh in here.

Good answer, thank you. Many FS17 were built, many without any spray rail. It is an option but is it worth the extra work? You decide.

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Jan 25, 2018 8:33 am

by silentneko

There in lies the issue, I don't think anyone has done this type set up on a FS17. I've seen spray rails on them and the FS14, but I don't think I've seen a reverse chine. Well think about it this way, weather it works or fails, I'll be able to pass the data along to the next guy, lol.

I over coated with neat epoxy last night to fill in some weave and stabilize the pockets I opened up with the awl. I have to say I'm pretty happy now. All my major areas of concern seem to be dealt with. Today I need to lay a little glass to deal with 2 areas I have some rocker in. Not a huge deal, but I'd rather do this then just fill it in completely with fairing compound.

Re: The Plytanic 2.0 - FS17 Build

Posted: Thu Jan 25, 2018 12:43 pm

by silentneko

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Jan 28, 2018 4:01 pm

by silentneko

Still haven't decided what to do on the chines/strakes... So I decided to go ahead with the rub rails.

1/4" leftover okoume cut to 1.5". I also make a few pvc clamps cause I was worried I would not have enough.

So I got the first section of the rub rail on. Now everyone repeat after me! YOU CAN NEVER HAVE ENOUGH CLAMPS! Even though I made some extra clamps them and the spring clamps I had really weren't strong enough to keep the ply in place because of the way the hull twists and curves. Not a huge deal as I have other clamps to use, then I used the spring clamps in between just to add pressure.

I think I'm going back to harbor freight tomorrow to get a few more clamps. So far I have found small 3" c-clamps to be great, and also the quick release clamps like these are probably the most useful and user friendly:

https://www.harborfreight.com/6-in-quic ... 62239.html

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Jan 28, 2018 5:21 pm

by OrangeQuest

silentneko wrote: ↑Sun Jan 28, 2018 4:01 pm

Still haven't decided what to do on the chines/strakes... So I decided to go ahead with the rub rails.

I was kind of liking the 2" ones you did on the new table saw a few days ago. I like you posting all your options and samples on the hull. I was thinking I may do something on my FS14 when I flip it again.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Jan 30, 2018 4:24 pm

by silentneko

Yeah I think I'm going with the 2" x 0.5" for the chines. I'm waiting on a feather board for the table saw to come then I'll cut some more out.

I got around to putting on the first layer of the rub rail on the port side.

After that I decided to start getting ready for fairing. I talked about converting an old sander to a power fairing board on another thread. well here you go. Simple, crude, and effective. I bought a cheap roll of 2.75" x 25' 80 grit, and built the board 18" long. I stapled some small chunks of sand paper under the blocks so the paper wont slip out. This should make fairing go a bit faster.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Jan 30, 2018 4:49 pm

by OrangeQuest

Interesting sander. very good idea!

I have the switch going out in mine and I want to replace it. Once I get another one I may pull the old pad off and see how a board can be mounted to make use of the cam. I can hard wire the switch on and just use the foot switch for my die grinder motor. I am just getting to the fun sanding parts!

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Jan 31, 2018 10:04 am

by Bogieman

Looking great!

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Feb 05, 2018 2:36 pm

by silentneko

I got the last layer of the rub rail on today. I'm not sure why, but this is always the point in my builds that I feel the hull goes from plywood to boat.

Every single one of my builds has had blood sweat and tears put into them, literally. Just a drop soaked into the plywood this time.

I can no longer stall any decisions on what I'm going to do about the reverse chines. I have some leveling of a few low spots to fix, but after that I'll do the chines and get ready to fair.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Feb 05, 2018 3:18 pm

by narfi

A blood sacrifice to the builders/maintenance gods.

This is a good sign.

Your boat will serve you well!

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Feb 05, 2018 10:58 pm

by Browndog

I agree with Narfi. A little blood is a good sacrifice.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Feb 06, 2018 7:12 pm

by silentneko

I didn't have much time today after running around and an anniversary lunch with the wifey. I decided to redo the drain plug tube I made before, the old one would have worked, but it was a little loser then I wanted.

After that, I started to level the hull before fairing. I had those 2 spots I added glass to before, but they still needed more work. I used a mix of milled fibers, wood flour and fumed silica to skim coat it, similar to my bonding adhesive. The next layers will be fairing compound, but after I put the chines on.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Feb 09, 2018 8:06 am

by pee wee

Sounds like you're dealing with it, not really a set back as much as being thorough takes more time than you anticipated. Your photo shows the level placed perpendicular to the keel, I assume you've also checked for flatness fore and aft, as that is more important.

Looking good, build on.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Feb 09, 2018 9:15 am

by silentneko

That's just where I set the level down so it wouldn't slide off. Every correction I'm working on is based on fore to aft leveling. Part of this is the stringer issue, because they didn't match the top of the frames they don't really support anything under it, hence the sagging between the frames along the keel. The sags on the outside are more due to the corrections I needed to make with the ply being out of square.

This is my first time using okoume, I've used meranti in the past. I went with the more expensive ply because of the weight savings. However one characteristic is it's more flexible then the meranti, great for making the bends, but with the frames being set 36" apart it doesn't have the rigidity to stay flat as well.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Feb 09, 2018 10:14 am

by Browndog

You are right about the okoume. It is nice and flexible which I agree makes for nice bends but can cause some”ripples” when unsupported as you describe.

Some of that seamed to disappear when the boat I am building was flipped and the stringers and frames and gravity helped to stretch everything a little bit. Then once the inside seams got taped everything stiffened up. Then the inside fiberglass cloth made it even better. Once the stringers got glassed in it got very strong.

I have come to appreciate that this building technique makes for a very solid boat since every time something is added it gets taped in and the boat gets progressively stronger and stiffer. I remember Fishgtr recently comparing his fs18’s performance to a Hell’s bay boat and him commenting on the differences being readily apparent from less vibration and rattling.

Your build is looking really good. Keep it up!

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Feb 09, 2018 10:22 am

by silentneko

The monocoque structure adds tons of strength no doubt. Thing is the rippling needs to be dealt with prior to flipping, or you can't really fair the hull before painting. If I had the resources and room I would flip.it, install the stringers, then flip it back and then fair, but that's not practical.

I think it might not be a bad idea given the materials to decrease the frame spacing to 24". I would have gladly cut another frame or 2 over having to do filling.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Feb 09, 2018 12:43 pm

by pee wee

I recall reading that some builders have screwed in a temporary 2x4 to flatten out the planing portion of the hull until it gets glassed. You'd have to crawl under there to install it, but is that a possibility?

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Feb 09, 2018 1:15 pm

by silentneko

It would have been prior to glassing. Or even prior to hull panel assembly. I've already done my glassing, and most of the filling, so it's to late for me.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Feb 09, 2018 10:56 pm

by narfi

I took a 6ft straight edge to the back of my boat now that the glass is on and cured.

I had ~1/8" hook give or take all the way across.

I re-read the plans and up to 1/4" is acceptable.

I went back and looked at your pictures and it looks from the marks on your tape that is about what you had as well.

I am just figuring it out as I go, but if I read your marks right and I read the plans correctly I think we are in good shape and no need to sweat the small variations?

Re: The Plytanic 2.0 - FS17 Build

Posted: Sat Feb 10, 2018 12:16 am

by Fuzz

I think Narfi called this one correct. I recall JM stating he knows there will be a little hook with all the tape build up at the transom. I think he even stated he counts on it for running trim. Just my memory here and I could be mistaken.

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Feb 19, 2018 1:28 pm

by narfi

Any progress on your chines?

I was hoping to start cutting some trial triangles this weekend but wasn't able to make the time.(energy)

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Mar 13, 2018 12:03 pm

by silentneko

Fuzz wrote: ↑Sat Feb 10, 2018 12:16 am

I think Narfi called this one correct. I recall JM stating he knows there will be a little hook with all the tape build up at the transom. I think he even stated he counts on it for running trim. Just my memory here and I could be mistaken.

If that were the case I'd leave it, but I don't have hook, I have rocker. Even with the tape built up the transom drops about 1/8", so to make it more level I filled it. It looks fairly level now.

Re: The Plytanic 2.0 - FS17 Build

Posted: Tue Mar 13, 2018 12:04 pm

by silentneko

I made some progress, but it took a while to get sorted. I tried to just butt join parts as I went along, but it made an odd angle along the curves. The same thing happened when I tried to just kerf cut the areas that needed the most bending. So I ended up splicing 3 sections using 45 degree angles, the forward sections were tapered the last few inches. I shortened them a little from my original plans after some thinking to 140". So it all bent evenly I kerf cut them every 4 inches.

Splicing

Attached

They are about 5/8" high and 1.5" wide.

Shaped and filled

Glassed

I'm fairly happy with the outcome. In the pics it looks a little uneven because of the shading of the wood and filler, but once it gets faired and painted on color it will look pretty good.

Re: The Plytanic 2.0 - FS17 Build

Posted: Wed Mar 14, 2018 2:55 pm

by silentneko

I'm pretty much done with glass work now on the outside. I decided to add a second layer of glass to the chines since they are made of wood this will give them plenty of protection. If a strike happens hard enough to damage them they will be easy enough to repair, but they will act as a sacrificial part to keep the damage away from the hull. They will get coated in HBN/Epoxy too.

Next I turned my attention to the drain plug tube I made earlier. I'm glassing it in now so I can fair it smooth along with that whole area.

I think I marked it straight? LOL, it's kind of hard to tell after applying thickened epoxy to level the hull. It might be 1/16" off which is good enough.

I am just gluing it in on the top right now, I'll go back later and fill the area around it. This turned out to be the best way to keep it in place. I left it proud by about 1/4" this was I can fair all around it, then grind it level when done.

Re: The Plytanic 2.0 - FS17 Build

Posted: Fri Mar 16, 2018 8:46 pm

by silentneko

Time to itch. Sanded the bottom to get it ready for the first coat of fairing compound.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Mar 18, 2018 5:04 pm

by silentneko

I got a bit of fairing compound spread out, just a skim coat to start. I think I'm mixing it to thick, I went through about 1/3 my mix just to do this. I have some left over west systems fairing mix and some glass microspheres I can use once I run out. Hopefully it will be enough, if not I'll order some more soon.

I think I'm going to roll on a neat coat or two to the sides to get them closer prior to fairing them. I do have a wave on each side toward the stern where I tried to fix some gaps, nothing major, but I need to decide if I will fix it or not.

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Mar 18, 2018 7:12 pm

by Jeff

Nice initial fairing work Silentneko!!! Jeff

Re: The Plytanic 2.0 - FS17 Build

Posted: Sun Mar 18, 2018 9:13 pm

by Bogieman

Looking good, Silentneko! BTW, always curious about clever"handles". Care to to enlighten on it?? I also wanted to mention that the FS17 is one of my favorite powerboat designs and I actually bought the FS17 plans one year ago. I studied the FS17 plans for several months before making the decision to go with the AD16 sailboat. Anyway, the hull is looking great and I'll be following your build along the way.

Bogie

Re: The Plytanic 2.0 - FS17 Build

Posted: Mon Mar 19, 2018 10:03 am

by silentneko

Nothing to clever about my handle really. Neko is cat in Japanese. I'm a big guy, but in my youth I walked soft and was fairly quiet. I'm more of a bull in a China shop now, lol. Being around friends who were all into martial arts I got the nickname Neko.