Rudder

Making the rudder has caused me more head scratching than any other part of this build. As allowed for in the Moonfish plans, I am using Sunfish rig and foils. The challenge is finding out the exact dimensions of the foils - particularly the rudder.

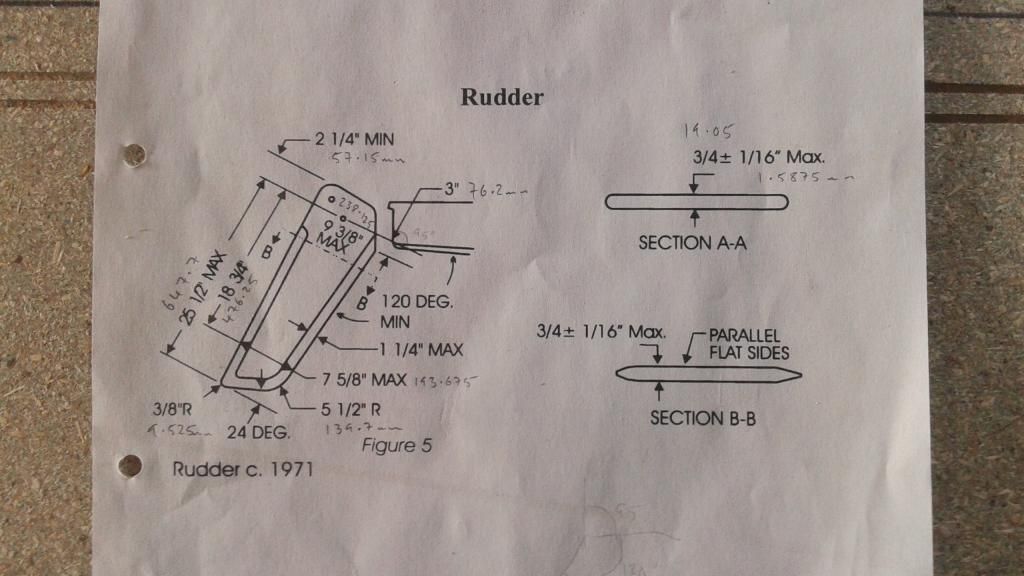

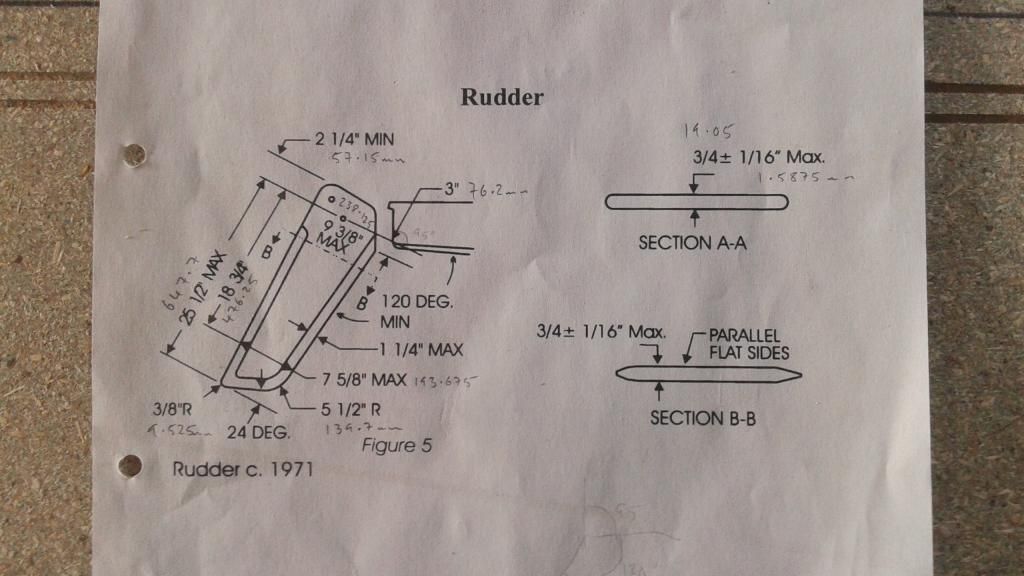

The Sunfish class regulations give this information:

While there are enough dimensions to work out the size and shape of the bottom part of the foil, there is nothing about the size, angles, curve radii or mounting holes (for tiller, rudder head and tension spring). In an ideal world, I would find an existing foil and just take the dimensions from it - but Sunfish aren't all that common here in the UK.

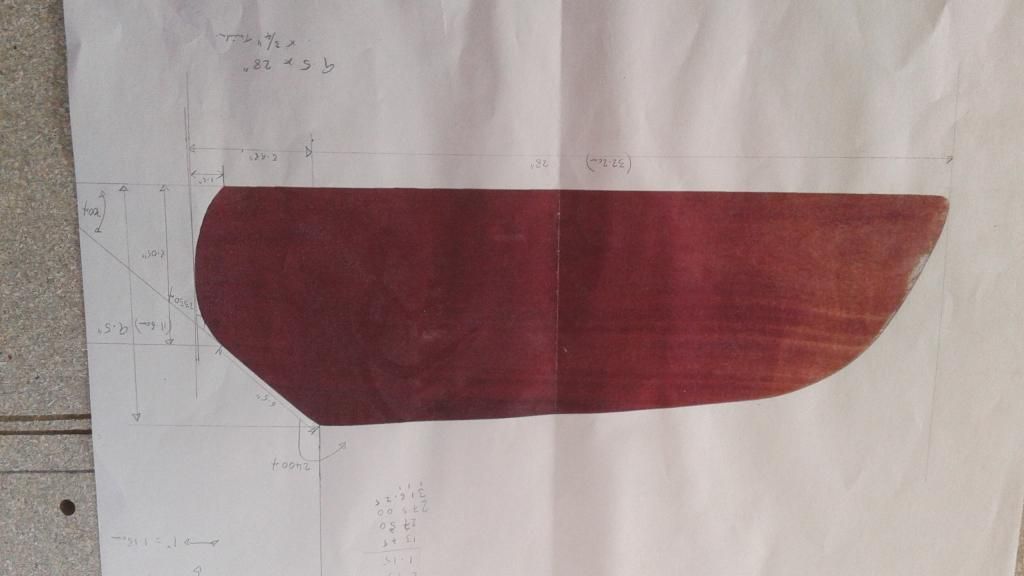

So what I did was find the clearest photos that I could of the foil and the rudder head/tiller on the web and print them out blown up to the largest size I could without loosing resolution:

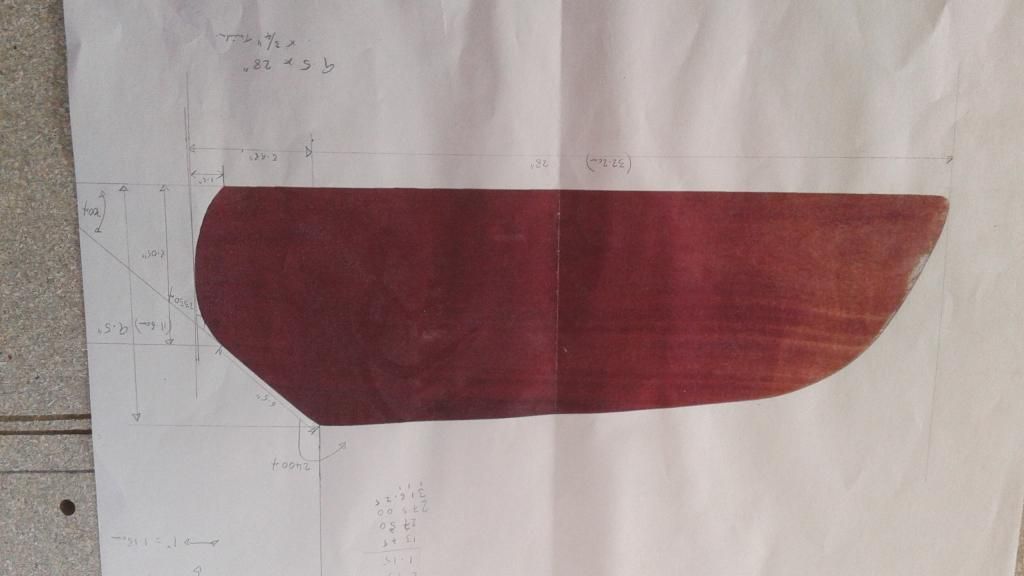

By careful measurement of the photos (in both x and y axes, to take into account probable distortion of the photo views and printing/enlarging processes and all the necessary angles and radii) and comparison with the plan and the Sunfish rudder head and tiller plates that I had bought, I was able to rough out a hardboard template:

I then fitted the rudder head and tiller plates to the template which allowed me to refine the rough shape and position the three holes:

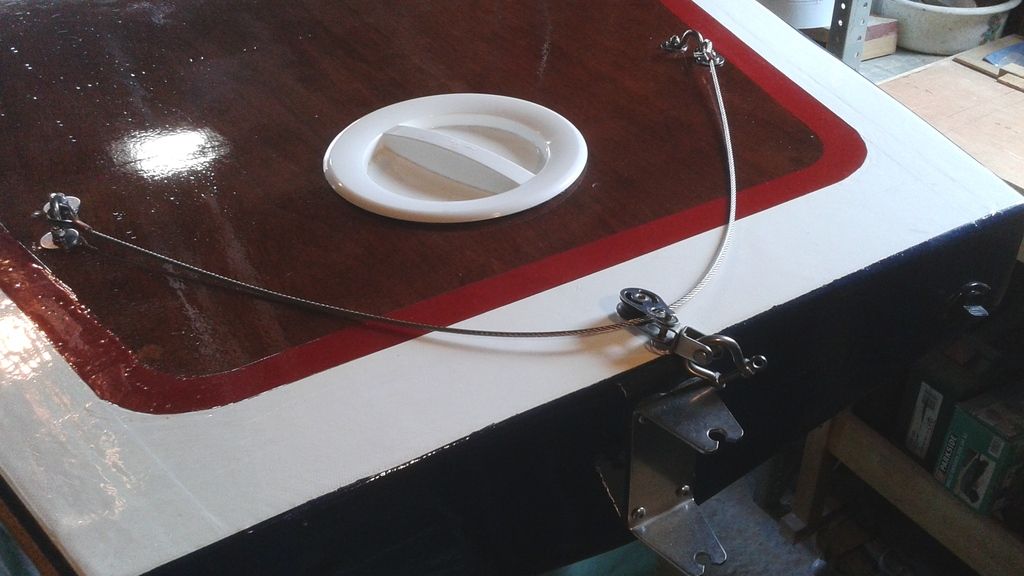

This whole arrangement allows the foil to kick up, yet be held securely in either the 'down' or 'up' positions without the need for lines.

The Sunfish class regulations give the thickness of the foils as 3/4" (+/-), which matches the gap in the rudder head. To achieve a blank of this size, I had to laminate three sheets of ply: one of 12mm, one of 6mm with one of 4mm sandwiched between them:

which worked well after a night curing under quite high, but uniform pressure.

I then marked out the edges and shaped them down, mostly using a low angle block plane (with a small sureform in places), finishing off with sandpaper. There were some rough spots left where some of the rougher filler laminations of the ply were exposed; I filled these with wood filler and then sanded back again to achieve smooth curves and corner radii. The whole thing was then stained with mahogany wood dyes - as I had done on the deck of the hull.

You will see that the three mounting holes have been enlarged (to 20mm with a forstner bit). These will be filled with epoxy before being drilled out again to the exact sizes. This will give me mounting holes that are (a) more robust than bare wood and (b) impervious to water penetration.