Page 1 of 1

FS13 - Bootje

Posted: Mon Nov 16, 2015 8:23 am

by Gramps

Well after years and years of planning to build something, buying multiple sets of plans and feverishly following many great builds here on the Bateau forums, I started!

I am naming this little boat, Bootje. Bootje is a Dutch word which I understand to mean "little boat". My wife's family is from the Netherlands and from that I chose the name in her honor.

So without further adieu, here we go. Picked up the wood from a local supplier here in Houston on Saturday morning, along with a bunch of other lumber to build storage shelves to get junk off the floor and give me room to work. Started laying out the panels Saturday night, spent about 2 hours to layout the hull bottom and sides.

I cannot say how easy it was to layout and draw the lines. This was my biggest worry in building the boat, but really, it is easy enough a trained monkey could do it.

That was it for Saturday night. Cleaned up and off to bed to rest up for the Renaissance Fair on Sunday.

Back home Sunday afternoon it took about an hour to cut out the panels. A circular saw with a fine cut / trim blade set at 6mm deep was the ticket. Slow and steady lead to this:

So that is where we sit now. I've got to figure out the nesting to cut transom panels to about 17.5" tall for a small outboard, hope I can fit the pieces without having to buy another sheet of wood. Also waiting on the epoxy and glass to arrive from Bateau, should have that on Wednesday. But, I'm out for most of the week on a business trip so the splicing will have to wait.

I'm stoked about this Bootje!

Re: FS13 - Bootje

Posted: Mon Nov 16, 2015 8:47 am

by Cracker Larry

I'm glad to see a FS13 get started

Re: FS13 - Bootje

Posted: Mon Nov 16, 2015 8:54 am

by Noles309

Alright man! Its about time! I'm looking forward to this.

Re: FS13 - Bootje

Posted: Mon Nov 16, 2015 9:57 am

by gonandkarl

Hi,

We have 2 facts in common, I will build an FS13 besides my AD14 and my wife is also from the Netherlands. I have ordered the plywood for the boat today with an expected delivery date on January 15th 2016. You beat me at the start already by 2 months. The big advantage for me is that I can follow your build and see all your pictures which you hopefully carry on posting.

All the best for your build of Bootje.

Greetings from Karl ( Austria )

Re: FS13 - Bootje

Posted: Mon Nov 16, 2015 10:45 am

by jacquesmm

No problem understanding Bootje, born in Belgium, I still understand Dutch.

Nesting: yes, it is well done. It's my son who did the drafting and he gave baseline locations on the nesting drawing.

Transom 17": that will be tight. There isn't much plywood left on the nesting drawing. You may get there with a patch work of leftover pieces.

Be generous with the fiberglass and it should work.

Re: FS13 - Bootje

Posted: Mon Nov 16, 2015 2:14 pm

by Gramps

Questions:

1. On the sole layout. From the forward portion of the sole to the first station (left to right), what is the distance? I come up with approximately 1'-5-1/2" or 442mm.

2. Transom knee height. If I go with a 17" transom in lieu of the 13" designed, do I need to raise the height of the transom knees? Currently the knee tops are on the same plane as the transom. Is this a rule that needs to carry over for higher transoms?

To clarify the 17" transom is to allow the motor to sit directly on the transom and have the cavitation plate level with the hull bottom. Most "15 inch" shaft motors are actually 16.5-17.5" from the bracket to the cavitation plate.

Re: FS13 - Bootje

Posted: Mon Nov 16, 2015 3:22 pm

by jacquesmm

Gramps wrote:Questions:

1. On the sole layout. From the forward portion of the sole to the first station (left to right), what is the distance? I come up with approximately 1'-5-1/2" or 442mm.

The total length = the length of the stringers to the frame A notch. We show the stringers on another drawing.

Yes, it is 441 mm or 17-3/8".

2. Transom knee height. If I go with a 17" transom in lieu of the 13" designed, do I need to raise the height of the transom knees? Currently the knee tops are on the same plane as the transom. Is this a rule that needs to carry over for higher transoms?

I would raise the knees according to the change in transom height. Check your outboard clamping, the wing nuts on some may interfere with the knees.

To clarify the 17" transom is to allow the motor to sit directly on the transom and have the cavitation plate level with the hull bottom. Most "15 inch" shaft motors are actually 16.5-17.5" from the bracket to the cavitation plate.

That is how it should be for planing. I know that those small outboards do not follow the 15" standard but the boat was designed fro trolling motors etc. It will work with a small outboard but there will be a learning curve for the operator.

That's another way to say not to take off full speed the first day or you will capsize here.

Re: FS13 - Bootje

Posted: Sun Nov 22, 2015 7:25 am

by michael c

Can't wait to see how it turns out!!! I'm seriously considering knocking one of these out before I start another big project. Please keep us updated.

Re: FS13 - Bootje

Posted: Sun Nov 22, 2015 8:11 am

by peter-curacao

LOL

Nice to see some Dutch here, when I saw the title of your thread I thought what the heck??

Good luck and have fun on your build

Re: FS13 - Bootje

Posted: Mon Nov 23, 2015 8:50 am

by Gramps

Thanks for the comments guys!

Jacques, GonandKarl, Peter - That's my extent of Dutch, except for stroopwafel! Those things are awesome!

Anyhoo, got more time yesterday to cut out the rest of the panels less the sole & knees. Going to glue & tape this evening and let them cure for a few days while we head north to visit family.

There is enough wood to get two (2) layers of the transom to 17" tall along with two shorter ~14" transoms and appropriate scrap to piece together. Below you can you see how I am making it work. I'll leave the spliced pieces a little large then come back with a template & router to clean them up.

Next step is a micro strong back and start to stitch! So far including setup, cleaning, and fussing , I'd guess I have about 9 work hours in so far. I could cut that down by at least 2 hours next time around, since I measured & re-measured every panel at least twice!

Re: FS13 - Bootje

Posted: Mon Nov 30, 2015 8:31 am

by Gramps

Got to work on the boat a bit more this past week. I spent about 1 hour Tuesday night and 2-1/2 hours last night (Sunday) getting more work done.

Tuesday was a day for joining panels and gluing the transom. I used 6oz biax tape, yes way overkill and not what JM spec'd, but I HATE woven fabric. Anyhoo, mixed up 12 ounces of epoxy for 63 inches of tape, wet out of ply and a tack coat for the transom pieces. This turned out to be a little too much but really only about 2 ounces. Mixed another 9oz batch for the transom glue which was about perfect.

Wet out plywood, wet out cloth, squeegee on peel ply, plastic, and then weights. Worked well for me!

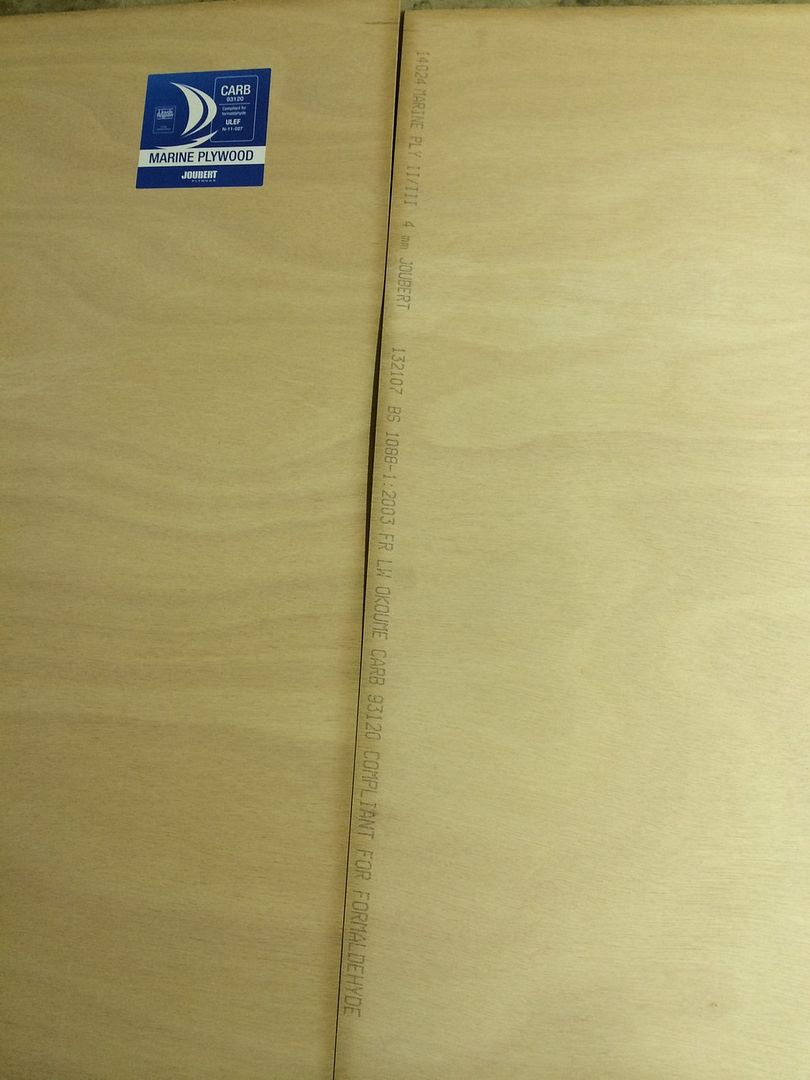

Headed out of town to visit family and came home to get this done Sunday. She looks like a Bootje!!

Need to build a table and some wedges to match the frame angles. She is a bit splayed out in these photos but all of the stitches are loose now.

Re: FS13 - Bootje

Posted: Mon Nov 30, 2015 9:11 am

by Noles309

Sweet!

Re: FS13 - Bootje

Posted: Mon Nov 30, 2015 10:41 am

by jacquesmm

If the stringers push against the transom, cut a little bit off, it will keep them straight.

Re: FS13 - Bootje

Posted: Mon Nov 30, 2015 8:17 pm

by Fuzz

Gramps, thanks for sharing. This is going to be a neat build. I have no need for one, nor is there a place I could use one if I had one, but it is sure neat to look at.

Fuzz

Re: FS13 - Bootje

Posted: Mon Nov 30, 2015 9:45 pm

by Cracker Larry

I have no need for one

Me either, but I'm going to build one anyway

nor is there a place I could use one

I've got plenty of places to use it. Me and dog might have a real good time with it in the swamp.

Re: FS13 - Bootje

Posted: Tue Dec 01, 2015 2:39 pm

by jacquesmm

BTW, I overlooked that:

Tuesday was a day for joining panels and gluing the transom. I used 6oz biax tape, yes way overkill and not what JM spec'd,

Keep in mind that Gramps is talking about the splices.

There is almost no tape on that boat. Inside, a little bit at bow, transom and along the keel but that's it no taped chine.

Later, you will fiberglass with 6 oz. all over everything with an overlap at the keel. Nothing more is needed.

Re: FS13 - Bootje

Posted: Tue Dec 01, 2015 5:19 pm

by jbo_c

How do you pronounce 'bootje'? Is it "boot-jay"? or "booge"? or something else? My brain insists on stopping to ponder this each time I cross this thread.

Thanks.

Jbo

Re: FS13 - Bootje

Posted: Tue Dec 01, 2015 9:14 pm

by Dougster

I'm following this thread too, and admire how neat it looks and how your zip tie stitching is going so well. I don't need one either but think I'll build one anyway too

Right now I'm fiddling with a 1/3 size model. I'm about where you are but may struggle a bit with the alignment and zip tie thing. I've been thinking about putting one of those fancy anchor lock trolling motors in front, but wonder about the trim. Maybe have to move the battery to the stern? With the remote control you could stand back from the stern and help things. I also wonder if walking around the seat, holding post, etc. to get to the trolling motor and lower or raise it would be a bit tippy

Sure would prefer a troll motor on the nose than the stern.

Random thoughts Dougster

Re: FS13 - Bootje

Posted: Tue Dec 01, 2015 9:23 pm

by RCC-SKIFFS

From my experience running small Skiffs in our NMZ, without the extra weight in the back handling will be sloppy. Using an Ipilot or copilot different story

Re: FS13 - Bootje

Posted: Wed Dec 02, 2015 6:39 am

by stickystuff

A little tip for other builders. The drain hole in the transom area can be cut out very neatly with a hole saw if you have one . I have prob 30 dif. hole saws and I picked out a 6' one that I had. lay out your transom, mark a center line and a flat line where the bottom of the sole lines up with the drain. Using a 1/4" arbor on the hole saw drill a hole flush with the bottom of the drain. Next, take your hole saw and tilt it at approx 45 deg. angle. I start out in reverse with the drill. This way it won't grab and jump making a nasty cut. Then switch to forward and carefully cut the hole while the saw is at this angle. Watch close to stop the hole saw at the bottom of the drain surface. Remove the saw and finish the final cut with a jig saw. Sand all the edges and you have a neat and clean drain hole.

Re: FS13 - Bootje

Posted: Tue Dec 08, 2015 2:22 pm

by Gramps

How do you pronounce 'bootje'? Is it "boot-jay"? or "booge"? or something else? My brain insists on stopping to ponder this each time I cross this thread.

Wife says it is "boo" - "che" I'll have to ask the Oma at Christmas for an official pronunciation.

I have to admit, I don't have a need for this either. But I wanted to build one! It is small and cheap enough to store/paddle/transport as a kayak/sup if it doesn't have power. So it'll stay around, plus I got eyes on some property with a 6 acre lake!

Sticky - thanks for the tip!

Dougster - Minn Kota just released a self deploy / self stow troller. It's the Riptide Ulterra and costs

nearly MORE than a brand new 5hp motor! But it might just be the ticket! Edit: The troller starts at $2,000 and a Merc. 5hp is $1,500!!!

Re: FS13 - Bootje

Posted: Thu Dec 10, 2015 10:04 am

by Dougster

Wow, that may be nice if it's reliable, but kinda silly pricey. I suppose a little outboard is more practical. Still, I'll go peek at that Ulterra for grins. BTW, I'm still fool ling with the FS13 model I'm making. I broke a bottom panel of the scrap Luan I had and went to Home Depot. They had a sheet of skinny, bendy little door skin stuff for 8 bucks so I brought one home and cut two new bottom panels. Today I"ll play with stitching them up. Doing the model is enlightening as you can fool around with the stitch up easily and really get to understand that process. A little this and that makes a big difference.

Hill Country Dougster

Re: FS13 - Bootje

Posted: Thu Dec 10, 2015 10:28 am

by jacquesmm

When you build a model, you must also scale down the thickness of the plywood.

Re: FS13 - Bootje

Posted: Mon Dec 14, 2015 10:34 am

by Gramps

Re: FS13 - Bootje

Posted: Mon Dec 14, 2015 8:46 pm

by Dougster

Dang that transom looks big! That's the 17" option for an outboard for sure. Did you cut the scupper drain from the start or wait to see if it lines up with the sole first? On my model, the drain is a bit high as I drew it. It's fun to see it coming along real size. You gonna use outboard power or troll motor, or still pondering?

Hill country Dougster.

Re: FS13 - Bootje

Posted: Tue Dec 15, 2015 8:23 am

by Gramps

Yeah she is a biggun Dougster! I like the look that some production boats have rather than the arc JMM uses. Do remember the side panels are only about 9" tall! So the additional 8" for the outboard makes it look rather humongous!

I cut the drain from the start.... had not even given thought to the final elevation in relation the sole.

So as of now, I have no idea how it will fall in relation! Guess that'll get checked tonight.

Planing on paddling at first and adding a motor later. There are a few clean 5hp Mercury 2 strokes down in here Houston, would be a really nice fit for the boat. But, last time driving a tiller boat I was thrown out in a hard unintentional turn. This boat will be tested via paddle only for now.

Re: FS13 - Bootje

Posted: Tue Dec 15, 2015 5:40 pm

by ScottR

Gramps,

Quick question and forgive my ignorance but what are the PVC pipe pieces for?

Thanks

ScottR

Re: FS13 - Bootje

Posted: Wed Dec 16, 2015 10:29 am

by Gramps

Scott the PVC dowels help keep the panel edges aligned. This is my first build and everyone recommends using them, so I did.

Taken from BayportBob's FS18 Blog

"The other huge benefit of the dowels is that they help not only align the strips (edges), but also evened out the adjacent edges and greatly reduce or eliminated the "stair stepping" I experienced by just using the tie wraps alone."

Re: FS13 - Bootje

Posted: Wed Dec 16, 2015 12:54 pm

by jacquesmm

Gramps wrote:Scott the PVC dowels help keep the panel edges aligned. This is my first build and everyone recommends using them, so I did.

Taken from BayportBob's FS18 Blog

"The other huge benefit of the dowels is that they help not only align the strips (edges), but also evened out the adjacent edges and greatly reduce or eliminated the "stair stepping" I experienced by just using the tie wraps alone."

I was just going to say that . . .

Thanks for the post.

Re: FS13 - Bootje

Posted: Fri Dec 18, 2015 2:04 pm

by Dougster

Just noticed this system. Pricey at $850 Canadian but no battery needed, so who knows

http://www.h2proped.com/

http://www.h2proped.com/

Wandering mind Dougster

Re: FS13 - Bootje

Posted: Fri Dec 18, 2015 3:12 pm

by terrulian

Re: FS13 - Bootje

Posted: Fri Dec 18, 2015 4:37 pm

by jacquesmm

Dougster wrote:Just noticed this system. Pricey at $850 Canadian but no battery needed, so who knows

http://www.h2proped.com/

http://www.h2proped.com/

Wandering mind Dougster

Very nice system, I love it.

I emailed them to see if we could get a deal for our builders.

BTW, that's about $ 600.00 US and no hole in the boat.

Re: FS13 - Bootje

Posted: Mon Dec 21, 2015 9:34 am

by Dougster

Very cool Jacques, keep us informed on how that goes. As I think about it, that's a better price than going with a trolling motor and dang heavy battery. Less trouble, less noise, and it transfers easily to other boats. Plus you can get a little exercise. Hope they contact you.

Dougster

Re: FS13 - Bootje

Posted: Mon Dec 21, 2015 9:47 am

by Gramps

That's slick Dougster! Good find!