Well, I found this over on 2Coolfishing. Thought it was interesting and was curious what Jacques and others think about the idea. Worth the trouble or not?

Frank

http://2coolfishing.com/ttmbforum/showt ... p?t=162031

Venting a tunnel

-

Oceola

- Active Poster

- Posts: 289

- Joined: Thu Apr 22, 2004 7:11 am

- Location: Houston, Tx / New Smyrna Beach, FL

Venting a tunnel

Craftsmanship means no wrinkles in your duct tape.

I discussed that with someone at the Crystal River meeting. Was it you?

(I'm bad with names, especially the screen names we use here.)

In theory, it makes sense. It should work.

I would be interested to read some performance tests from somebody who would build the boat without the vent, run it then fit a vent and compare.

If somebody test that for example on the XF20, I would refund the cost of the plans.

I would like to know if I miss something.

The tunnel creates a vacuum or suction. I have seen paint abraded from the tunnel because of that. Water boils in there. It makes sense that a vent would even the pressure but it may also aerate the prop.

(I'm bad with names, especially the screen names we use here.)

In theory, it makes sense. It should work.

I would be interested to read some performance tests from somebody who would build the boat without the vent, run it then fit a vent and compare.

If somebody test that for example on the XF20, I would refund the cost of the plans.

I would like to know if I miss something.

The tunnel creates a vacuum or suction. I have seen paint abraded from the tunnel because of that. Water boils in there. It makes sense that a vent would even the pressure but it may also aerate the prop.

Jacques Mertens - Designer

http://boatbuildercentral.com

http://boatbuildercentral.com

-

Oceola

- Active Poster

- Posts: 289

- Joined: Thu Apr 22, 2004 7:11 am

- Location: Houston, Tx / New Smyrna Beach, FL

Jacques wrote:

"I discussed that with someone at the Crystal River meeting. Was it you?"

No, sorry. I wanted to make the meet, on the way to my daughters in New Smyrna, but couldn't make it. Maybe next year.

I thought that you, with your knowledge of hydrodynamics would be interested, understand the application, and see if it could benifit your tunnel designs.

Frank

"I discussed that with someone at the Crystal River meeting. Was it you?"

No, sorry. I wanted to make the meet, on the way to my daughters in New Smyrna, but couldn't make it. Maybe next year.

I thought that you, with your knowledge of hydrodynamics would be interested, understand the application, and see if it could benifit your tunnel designs.

Frank

Craftsmanship means no wrinkles in your duct tape.

-

Spokaloo

- * Bateau Builder - Expert *

- Posts: 4064

- Joined: Tue Aug 22, 2006 5:29 pm

- Location: Spokane, Wa

- Location: Spokane, Wa

- Contact:

Gpratt, I might add a couple little pieces to your list.

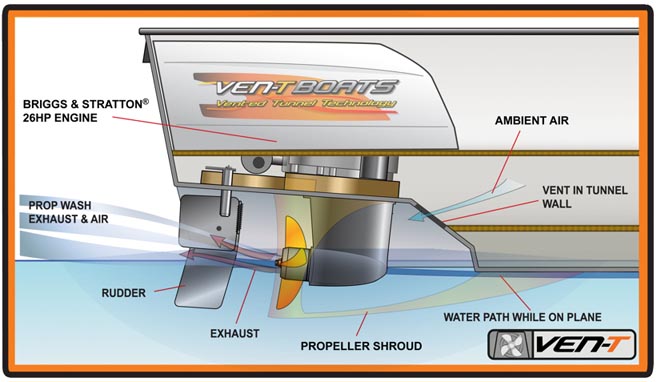

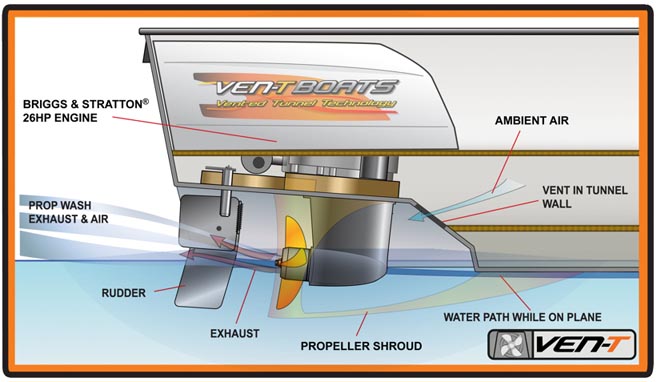

Let's try just venting the tunnel first. What that will do is allow the tunnel water to equalize in pressure with the surrounding water and reduce that "suction". Do keep in mind that this test was run on regular planing hulls without tunnels to see if there is a "suction" under hulls. The result was a resounding no, as there was a geyser back there. In the tunnel, it may be slightly different, but I do know some of the high-speed boats use forced air from a fan or from air scoops.

Secondly (and a jackplate will be most beneficial here), once vented, try using a supercavitating prop. Venting the tunnel might make for some aereated water coming out, which a supercav prop will deal with handily. I think with the vented tunnel, this will be a key element.

This might increase speeds substantially, it might not, but Id love to see some empirical data from GPS, close measurement of the mods, prop location in the waterstream, and airflow meter (a small wind gauge could do this) to see how much air is being introduced to the tunnel, and overall trim angle changes.

Fun game!

E

Let's try just venting the tunnel first. What that will do is allow the tunnel water to equalize in pressure with the surrounding water and reduce that "suction". Do keep in mind that this test was run on regular planing hulls without tunnels to see if there is a "suction" under hulls. The result was a resounding no, as there was a geyser back there. In the tunnel, it may be slightly different, but I do know some of the high-speed boats use forced air from a fan or from air scoops.

Secondly (and a jackplate will be most beneficial here), once vented, try using a supercavitating prop. Venting the tunnel might make for some aereated water coming out, which a supercav prop will deal with handily. I think with the vented tunnel, this will be a key element.

This might increase speeds substantially, it might not, but Id love to see some empirical data from GPS, close measurement of the mods, prop location in the waterstream, and airflow meter (a small wind gauge could do this) to see how much air is being introduced to the tunnel, and overall trim angle changes.

Fun game!

E

This was the best description I saw on 2cool...

An unvented tunnel has the most drag, lowest top speed (least efficient) but shallowest running capability.

A vented tunnel with a contol valve allows you to pick between shallow water performance (vent closed) and more efficient deeper water operation (vent opened) which is most of the time.

A tunnel will always cause more drag and lower performance that a boat w/o one.My Beavertail B2 Tunnel has this. there is a valve that open and closes the vent. With the valve open it injects air into the tunnel releasing drag and increasing efficiency. With the valve closed, you get full flow through the tunnel.

In valve open mode, I run the JP all the way down. I start getting cavitation with the jp above 2 and lose water pressure with the jp above 4.

With the valve closed, I can run the JP all the way up on 6 with no cavitation or water pressure problems.

It works pretty well. There is about a 10% increase in speed when the tunnel is vented.

An unvented tunnel has the most drag, lowest top speed (least efficient) but shallowest running capability.

A vented tunnel with a contol valve allows you to pick between shallow water performance (vent closed) and more efficient deeper water operation (vent opened) which is most of the time.

-

Spokaloo

- * Bateau Builder - Expert *

- Posts: 4064

- Joined: Tue Aug 22, 2006 5:29 pm

- Location: Spokane, Wa

- Location: Spokane, Wa

- Contact:

Speaking of vented tunnels:

Granted this keeps the prop IN the tunnel, but its the concept that you are talking about.

Here is a link about vented tunnels:

http://www.nava.ca/power.htm

Now Im not particularly sure you will pull water into the cavity at this point, unless you have something forward of the tunnel to create a pressure wave. This would build a "wake" behind it that might fill the tunnel (like a tunnel stern seabright).

This is interesting to say the least, but data is needed!

E

Granted this keeps the prop IN the tunnel, but its the concept that you are talking about.

Here is a link about vented tunnels:

http://www.nava.ca/power.htm

Now Im not particularly sure you will pull water into the cavity at this point, unless you have something forward of the tunnel to create a pressure wave. This would build a "wake" behind it that might fill the tunnel (like a tunnel stern seabright).

This is interesting to say the least, but data is needed!

E

Jacques, Can I pick a set of plans?jacquesmm wrote:In theory, it makes sense. It should work.

I would be interested to read some performance tests from somebody who would build the boat without the vent, run it then fit a vent and compare.

If somebody test that for example on the XF20, I would refund the cost of the plans.

I would like to know if I miss something.

The tunnel creates a vacuum or suction. I have seen paint abraded from the tunnel because of that. Water boils in there. It makes sense that a vent would even the pressure but it may also aerate the prop.

I did just the test you wanted with my GF-16. I originally built it with the tunnel you designed for the XF-20 (albeit not quite as wide) and then cut a vent into it. I got about 15% better performance with the vent open versus when I put my hand over it. You can read all about this in my thread, linked to in my signature. There is one XF-20 builder that already took my data and vented his tunnel.

E, the vacuum formed by the water moving through the tunnel is substantial!

If there are more questions post them up. I've done the test and it works great!!!

Tim

-

majorgator

- * Bateau Builder *

- Posts: 1794

- Joined: Tue Apr 29, 2008 8:58 pm

- Location: High Springs, FL

Well I just don't know what to believe anymore. Sure, I can see how venting the tunnel will help with performance due to the vacuum effect. However, posts in this forum have offered conflicting information regarding the general effect a tunnel has on a boat.

One builder says that the vacuum pushes the back of the boat up, out of the water, thus creating a shallower draft. Then another builder comes along and says that the vacuum in the tunnel actually causes the back of the boat to pulled down into the water.

So what's the truth??

One builder says that the vacuum pushes the back of the boat up, out of the water, thus creating a shallower draft. Then another builder comes along and says that the vacuum in the tunnel actually causes the back of the boat to pulled down into the water.

So what's the truth??

We are only discussing the venting here.

I will look into those experiments that I missed but I would like some detailed data: boat and tunnel type, load, HP, speeds, vent size.

About the tunnel: yes, it reduces running draft because the water raise in a hump behind the boat and yes, its produces some suction and that pulls the stern somewhat down but not much.

I will look into those experiments that I missed but I would like some detailed data: boat and tunnel type, load, HP, speeds, vent size.

About the tunnel: yes, it reduces running draft because the water raise in a hump behind the boat and yes, its produces some suction and that pulls the stern somewhat down but not much.

Jacques Mertens - Designer

http://boatbuildercentral.com

http://boatbuildercentral.com

Who is online

Users browsing this forum: No registered users and 15 guests