First job is to rebuild the casting deck. The aft bulkhead is rotting away, and the deck itself is starting to get pretty soft. I also don't like the storage arrangement, as getting the anchor in and out of the hole is pretty tough, and everything else needs to come out to get to it. I think originally there was a piece of canvas that covered up the hole, but that is long gone.

The plan is to rebuild it in generally the same layout, but with a hinged hatch on the top deck. I'll divide the compartment left and right into a dry-ish area on one side and a wet side for the anchor and lines. I originally bought a Bomar hatch to use for this, but I've seen a few that don't weather well when exposed to the sun all day, and they look a little cheap, plus I think I can make something nice and it will be a fun project. This is the part I think I need a little help with.

The current deck also holds two floatation chambers, one on each side. I will be eliminating these. We really need the storage space, and this boat has had significant amounts of water in it a few times but never this far forward. The entire sub-floor is filled with foam as well as two large volumes on the stern.

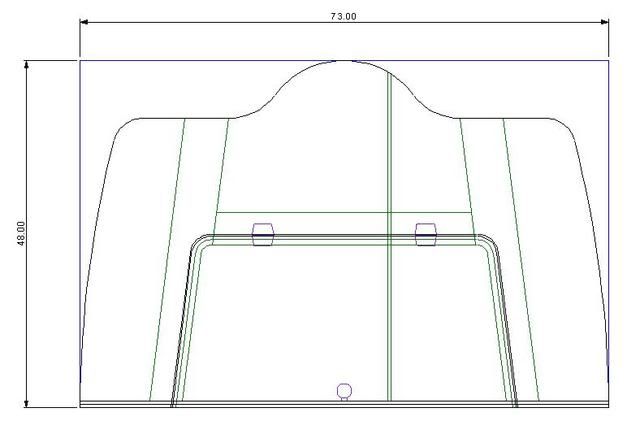

Hit up Marine Connection last weekend and picked up two 3x3" flush hinges and a 2" diameter spring-loaded latch. Here's a layout of what I plan to do:

The colors got lost a bit in upload. Blue is the outline of raw material (48 x 73), 1/2" Meranti that I've already bought at BBC. This is exactly the same size/shape as existing. The bulkhead is a solid version of what is there today, plus a full-width cleat across the back side. I'll make a pattern to route the hatch out of the deck, leaving a 1/4" gap. The hinges and latch locations are shown in purple. The green outline is a frame I'll build up from strips of 1/2" ply and bond to the under side of the deck, which will also form the drip rail. There is also a longitudinal bulkhead to divide the sections and reduce the span of the deck and hatch. This one will be a little tricky to get the contour just right to match the hull. I need a couple of drain areas through the bulkhead too.

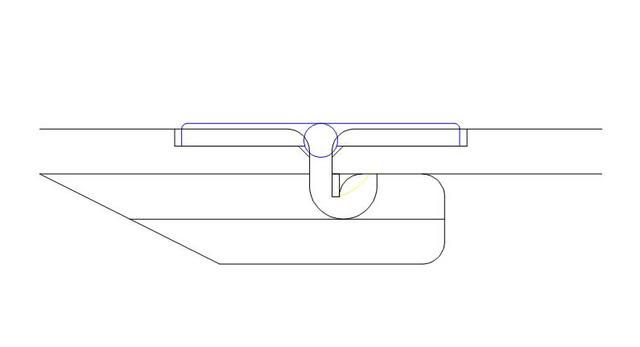

Here is a section through the deck, hatch, hinge, and frame/drip rail:

My plan is to build the frame onto the deck (after cutting out the hatch) and then use a core box router bit with an upper bearing to make the drip trough. This way the trough follows the outline of the hatch hole all the way around and drains out aft at the bulkhead. The drip edge will be formed on the hatch with fiberglass (found an explanation of this elsewhere on this site). The recesses for the cleat will be routed out of the deck prior to cutting the hatch out using a template that I'll have to make.

I'm open to any comments or suggestions on how to do this better. A few things that are in question:

-Will the deck be stiff enough with that span plus the frames?

-Where to fiberglass? Definitely on the top of deck, hatch, back of bulkhead, and anchor locker. If I glass the bottom of hatch or the lip it sits on I'll need to account for that thickness. What about glassing in the routed out area for the hinges?

-Are the frames & bond strong enough to support someone standing on the hatch?

-Should I add a gasket all around the lip (need to account for its thickness too). What material?

Next job is to patch the floors in the back end of the cockpit (and clean up the mildew!). I really should do the whole thing but I don't want the boat to be down for too long at a time.