20' Privateer roamer skiff project

-

greymare89

- Frequent Poster

- Posts: 68

- Joined: Mon Jul 15, 2013 9:57 pm

- Location: Long Island

20' Privateer roamer skiff project

It's been a while since I've been on here but I wanted to get back in the game. I recently purchased a 20' Privateer as a project. I was happy with the way the 18' Privateer came out with the help of everyone on this site so I figured I'd try a few new things on this build. Anyway the floor has soft spots as any 30 year old boat would but my main concern is the transom. It appears solid but I would like to raise it from a 20" to a 25" to eventually accommodate a 115 4 stroke engine. I don't think I'll have to do an entire stringer replacement like I did with the 18 but won't knows for sure until I get in there. What is the process of raising the transom 5"? I understand replacing the sole and glassing and tabbing it to the existing transom skin and hull sides but what is the best way to build up the transom skin where the 5" void for the motor well would be filled? Should the plywood core be layed in first and then glassed over both inside and outer side or should the 5 inch added skin be built up with glass first matching the thickness of the original transom skin and then glue in the plywood core with thickened epoxy? If building the skin first prior to laying in the core is the best way how do I go about doing it? Run tape or plastic wrap across the void, built a few glass glass layers and then peel bag the tape/plastic once the epoxy dries? Once that layer is in place it would be easy built up additional layers of glass to match the original skin thickness.I know this is super confusing and I'm trying to figure out the best way to articulate the question so if someone understands what I'm trying to say please send advice.

Re: 20' Privateer roamer skiff project

It is all going to depend on what you do to the transom.

If the transom core has to be replaced, it is very simple: you cut the new transom 5" higher as explained here:

http://www.bateau2.com/howto/shaftlength.php

If you don't replace the transom, it becomes more complicated and I would like to see pictures.

If the transom core has to be replaced, it is very simple: you cut the new transom 5" higher as explained here:

http://www.bateau2.com/howto/shaftlength.php

If you don't replace the transom, it becomes more complicated and I would like to see pictures.

Jacques Mertens - Designer

http://boatbuildercentral.com

http://boatbuildercentral.com

-

greymare89

- Frequent Poster

- Posts: 68

- Joined: Mon Jul 15, 2013 9:57 pm

- Location: Long Island

Re: 20' Privateer roamer skiff project

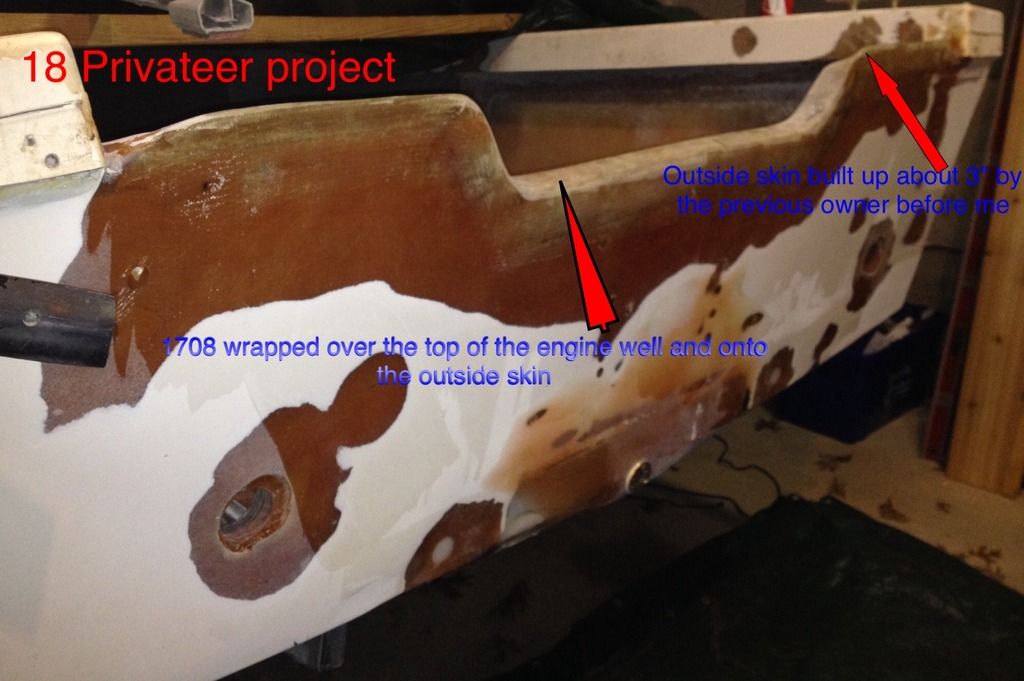

This is the finished 18 Privateer I finally completed fall of last year

And here's the new project

So here's the best pic I have right now of the 20 footers' transom. I think I'm just going to replace the core entirely because I'm sure it's damp from the screw holes over the years. I guess my biggest question is how I can built up the skin on the outside of the transom where the 5" will be filled in. I'll try and get a better picture from the inside to better explain. Thanks again to everyone with any input, this site has been a huge help.

And here's the new project

So here's the best pic I have right now of the 20 footers' transom. I think I'm just going to replace the core entirely because I'm sure it's damp from the screw holes over the years. I guess my biggest question is how I can built up the skin on the outside of the transom where the 5" will be filled in. I'll try and get a better picture from the inside to better explain. Thanks again to everyone with any input, this site has been a huge help.

-

greymare89

- Frequent Poster

- Posts: 68

- Joined: Mon Jul 15, 2013 9:57 pm

- Location: Long Island

Re: 20' Privateer roamer skiff project

I want to try and maintain the factory "lip" that all privateers have on the outer edge of the transom. I think if I did it this way it will give me something to feather the inside skin into instead of trying to wrap the 1708 over the top and onto the outside skin. When did the 18 footer I wrapped it over the top and onto the outside without the "lip" I'm mentioning now and it was a bit of a pain to get air bubbles out because of all the angles.....

I may be wrong but I believe the only way to achieve this "lip" is to build up the outside skin with glass first, (2) lay in the plywood sole,(3) glass the sole to the hull and then go back and clean up/sand the edge from building up the 5" added outside skin layer right? I think I'm over thinking it like I did with a lot of things but I want to have a plan going in instead of winging it and learning as I go.

This is how the 18 Privateer retriever came out prior to final prep and paint. I'm not sure how the original owner raised the top of the transom by about 3" with solid glass but it definitely helped when it came time to glass in the inner layers. The lip gives the inner skin layers something to bite onto

Re: 20' Privateer roamer skiff project

What is that lip? An extra thickness at the level of the clamp?

Jacques Mertens - Designer

http://boatbuildercentral.com

http://boatbuildercentral.com

-

greymare89

- Frequent Poster

- Posts: 68

- Joined: Mon Jul 15, 2013 9:57 pm

- Location: Long Island

Re: 20' Privateer roamer skiff project

The lip is the outside skin of the transom from what I can see. It's about 1/2" thick of solid glass

Re: 20' Privateer roamer skiff project

To rebuild it should be easy with sufficient layers of glass. To make it look neat may be challenge. It will require precise cutting of the glass layers.

Jacques Mertens - Designer

http://boatbuildercentral.com

http://boatbuildercentral.com

-

greymare89

- Frequent Poster

- Posts: 68

- Joined: Mon Jul 15, 2013 9:57 pm

- Location: Long Island

Re: 20' Privateer roamer skiff project

in your opinion what's the best procedure to attack building that outside skin up the 5"? (1) Place a temporary backing wrapped in plastic or some other non-stick surface on the inside (2) run a single layer of glass from side to side on the outside skin, (3) let that single layer set up and finally (4) build up the thickness on the inside cutting precise pieces of glass like you mentioned prior to match the thickness of the original outside skin and then (5) finally gluing in the marine plywood with thickened epoxy?

This is where I think I lose people with my question, I'm looking for the proper procedure of building layers of glass without the assistance of a wooden sole to add rigidity while the glass/epoxy sets up.

This is where I think I lose people with my question, I'm looking for the proper procedure of building layers of glass without the assistance of a wooden sole to add rigidity while the glass/epoxy sets up.

Re: 20' Privateer roamer skiff project

Building a dam is probably the best way: clamp a piece of plywood covered with plastic sheeting where you want that lip to end.

I am not certain that I understand the question, could you please post a picture of the part you try to build?

I am not certain that I understand the question, could you please post a picture of the part you try to build?

Jacques Mertens - Designer

http://boatbuildercentral.com

http://boatbuildercentral.com

-

Steven

- * Bateau Builder - Expert *

- Posts: 3148

- Joined: Thu Aug 22, 2002 1:00 am

- Location: Burleson Texas

Re: 20' Privateer roamer skiff project

You could grind a taper in the outer skin back from the edges of the cut out. Then put the dam set in from the outer skin the thickness of the skin. Fill in increasing the size of each successive layer until its flush with the outer skin and fair it in.

Who is online

Users browsing this forum: No registered users and 19 guests