Page 1 of 1

1981 FORMULA F233 RESTORATION - COPY

Posted: Sun Aug 01, 2010 8:40 pm

by NOTHING ELSE MATTERS

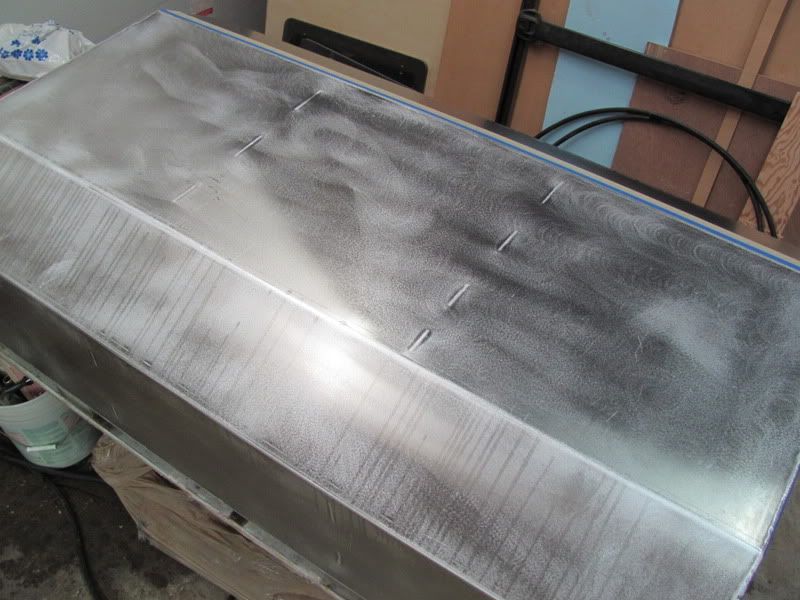

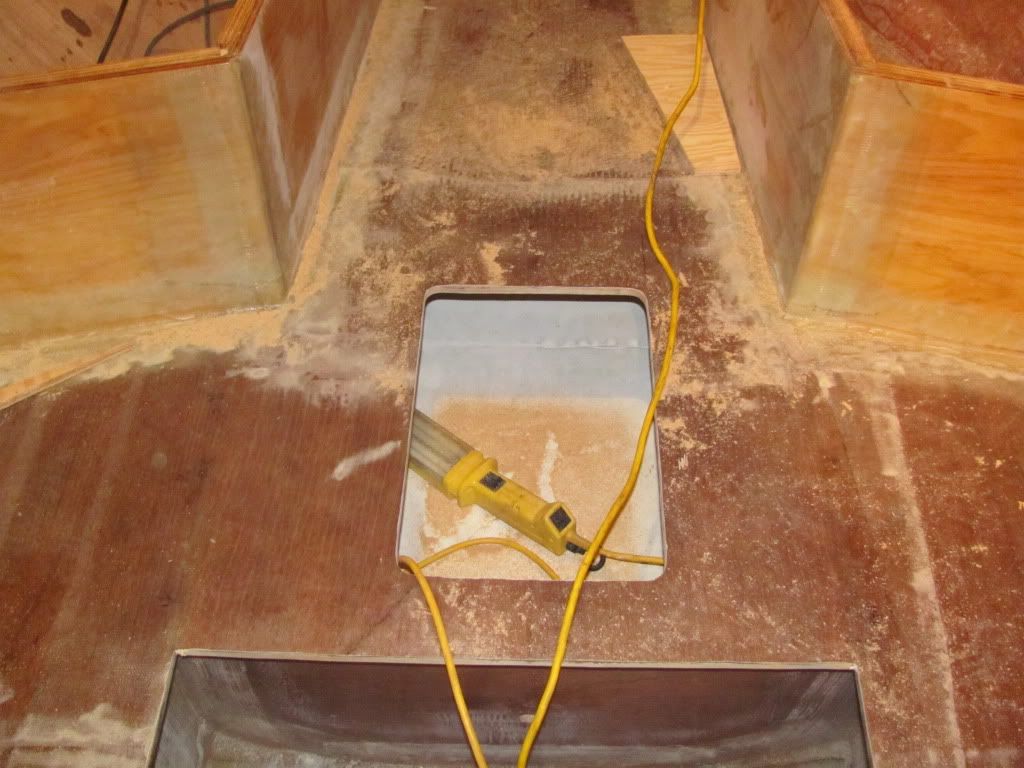

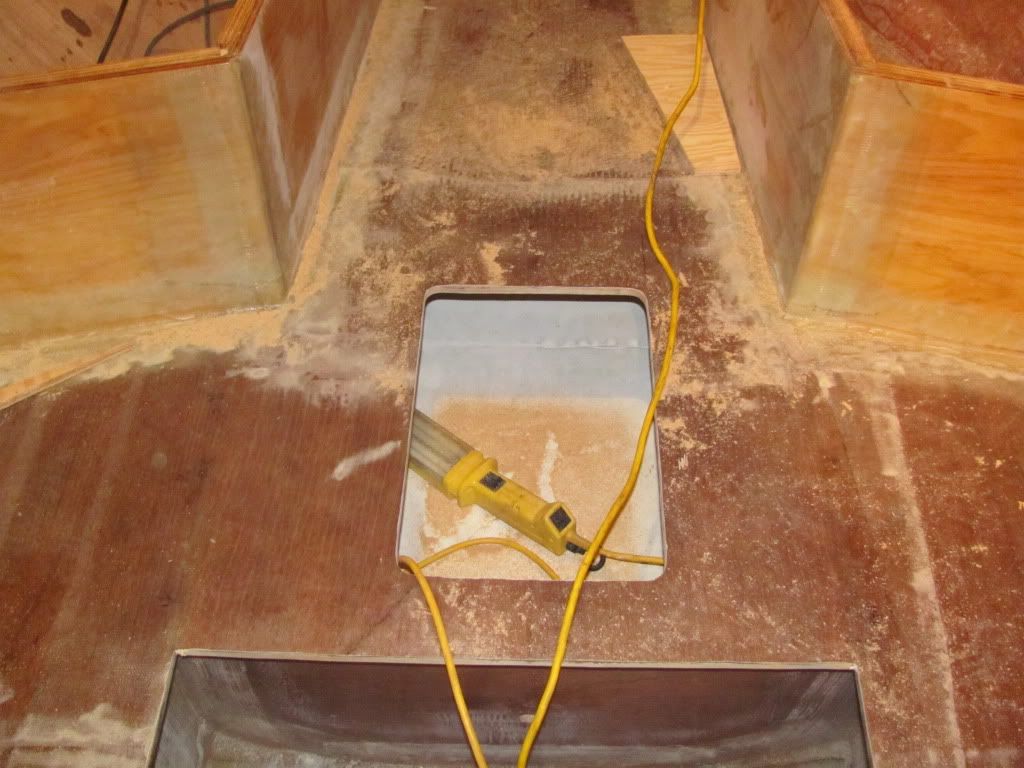

Hi everyone, finally i'm almost done ripping the Formula apart getting it ready for new stringers, transom and floor. Here are some pictures.

Boat was built with only two stringers 3/4 thick 27" apart made out lumber from the front of the boat to the bulkhead in front of the motor(is an I/O set up). No other bulkheads in the boat but all the empty areas were filled with soaked closed cell foam.

A few questions for the pros now.

1) I would like to install two additional stringers, one on each side.I was thinking of making the two main stringers out of double 3/4 plywood(BS1088) and the second ones just 3/4 plywood with some bulkheads in between. Is this O.K to do?

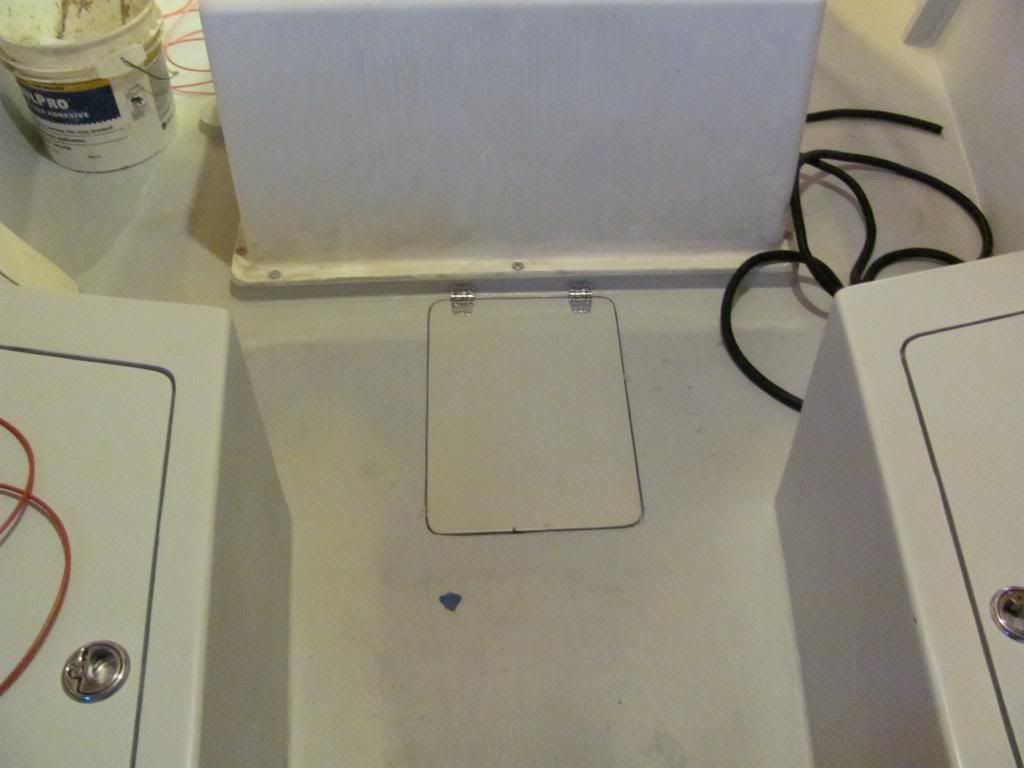

2) When i removed the "floating" stringers i end up with a lip of fiberglass as you see below. My question is when i grind that down flat should i remove also the flat piece of fiberglass holding the old stringer?

3) I also would like to thicken the bottom of the boat. How do i do that and what kind of glass do i use there?

Also, i wanted at the same time to fill the inside of the strakes to be even with the boats interior.

4) I also noticed that the interior floor is two different colors(was not painted or primed) some places is red and some places is

white.

Sorry for the long post and questions.

Shine, i'm also ready to place the order for everything but the plywood, including the glass to thicken the bottom of the boat(if i have to do that). The glass on the outside of the transom is 1/4" thick and i'm suppose to have no more than 2 1/4" total thickness according to Mercruiser. I would like to go with the Marine Epoxy brand, but i don't know if i should get medium or slow hardener, you tell me.

Thank you.

Re: 1981 FORMULA F233 RESTORATION

Posted: Sun Aug 01, 2010 8:50 pm

by NOTHING ELSE MATTERS

The pictures i posted suppose to show more area but for some reason they don't. Do i have to resize them?

Re: 1981 FORMULA F233 RESTORATION

Posted: Sun Aug 01, 2010 8:52 pm

by tech_support

1) I would like to install two additional stringers, one on each side.I was thinking of making the two main stringers out of double 3/4 plywood(BS1088) and the second ones just 3/4 plywood with some bulkheads in between. Is this O.K to do?

Sure, thats fine. More structure than original.

2) When i removed the "floating" stringers i end up with a lip of fiberglass as you see below. My question is when i grind that down flat should i remove also the flat piece of fiberglass holding the old stringer?

Yes, you should remove as much as possible.

3) I also would like to thicken the bottom of the boat. How do i do that and what kind of glass do i use there?

Also, i wanted at the same time to fill the inside of the strakes to be even with the boats interior.

no need to, especially considering the additional stiffeners you will be adding

4) I also noticed that the interior floor is two different colors(was not painted or primed) some places is red and some places is

white.

red is the color of the glass, the white is some overspray of gelcoat

Shine, i'm also ready to place the order for everything but the plywood, including the glass to thicken the bottom of the boat(if i have to do that). The glass on the outside of the transom is 1/4" thick and i'm suppose to have no more than 2 1/4" total thickness according to Mercruiser. I would like to go with the Marine Epoxy brand, but i don't know if i should get medium or slow hardener, you tell me.

Thank you.

Marinepoxy is good, I would get all slow hardener

Re: 1981 FORMULA F233 RESTORATION

Posted: Sun Aug 01, 2010 9:08 pm

by NOTHING ELSE MATTERS

Shine, thank you for the super quick reply. Do you need any more specifics as to how much material do i need?

I will also need some closed cell foam. Does that have any shelf time? Also, how do i figure how many gallons do i need?

Thank you.

Re: 1981 FORMULA F233 RESTORATION

Posted: Sun Aug 01, 2010 9:29 pm

by sitandfish

NOTHING ELSE MATTERS wrote:The pictures i posted suppose to show more area but for some reason they don't. Do i have to resize them?

I think most people know that they can open your pictures in a new window if they want to see more of the areas. Your pictures are fine.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Aug 03, 2010 10:16 am

by NOTHING ELSE MATTERS

Another question for the pros.

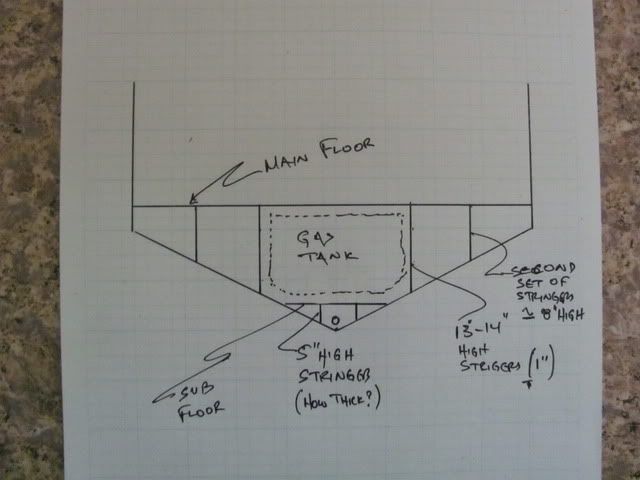

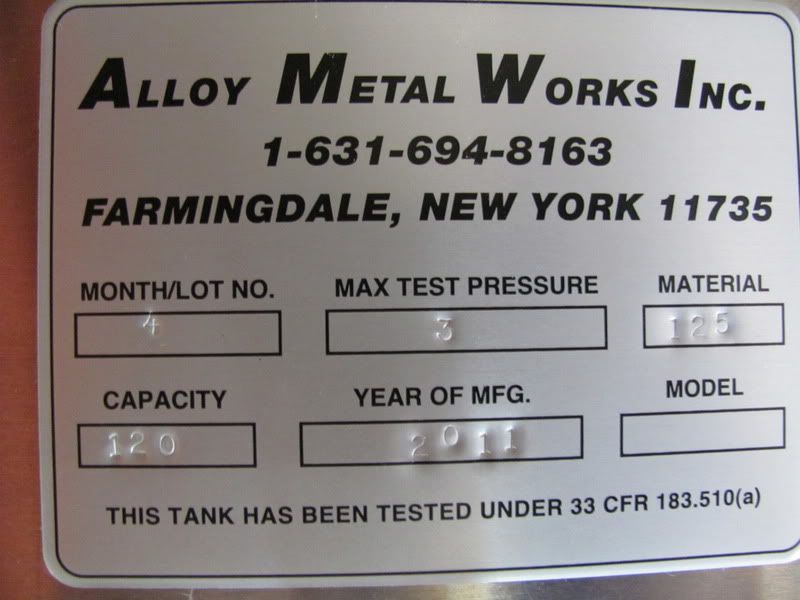

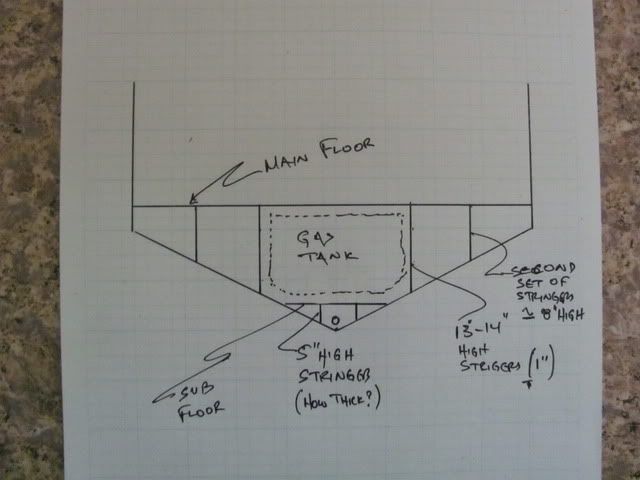

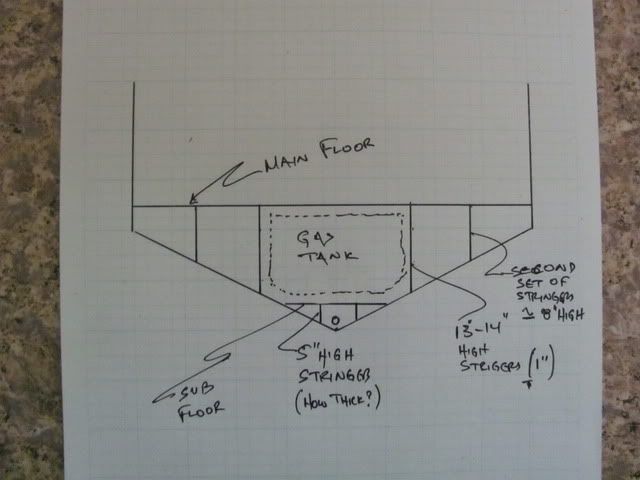

By the gas tank area i wanted to install either stiffeners lay down flat if i go with a "v" bottom tank, or make a sub floor and install 3-4" high stringers to install a flat bottom tank.

My question is:

1) What kind of material do i use(i.e flat 2X6 lumber or flat doubled 3/4 ply 6" wide) for the flat stiffeners ?

2) What kind of material do i use to make 3-4" high stringers ? (I think this is no brainer, plywood, right?

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Aug 03, 2010 11:19 am

by JGB

shine wrote:1) I would like to install two additional stringers, one on each side.I was thinking of making the two main stringers out of double 3/4 plywood(BS1088) and the second ones just 3/4 plywood with some bulkheads in between. Is this O.K to do?

Sure, thats fine. More structure than original.

Joel,

Are 1.5" stringers (double 3/4 plywood) required here or would 3/4" stringers (double 3/8 plywood) be OK? Seems like he said original stringers were 3/4" and many other boats here have used 3/4" stringers.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Aug 03, 2010 11:37 am

by tech_support

By the gas tank area i wanted to install either stiffeners lay down flat if i go with a "v" bottom tank, or make a sub floor and install 3-4" high stringers to install a flat bottom tank.

My question is:

1) What kind of material do i use(i.e flat 2X6 lumber or flat doubled 3/4 ply 6" wide) for the flat stiffeners ?

2) What kind of material do i use to make 3-4" high stringers ? (I think this is no brainer, plywood, right?

Plywood for both, I would standardize and use 3/4" for those parts. This is a big and heavy boat, no need to skimp.

for the long stringers, you should use two layers of wood to make the stringer one pieces (2 x 3/8" to make 3/4" stingers, or 2 x 3/4" to make 1.5" stringers)

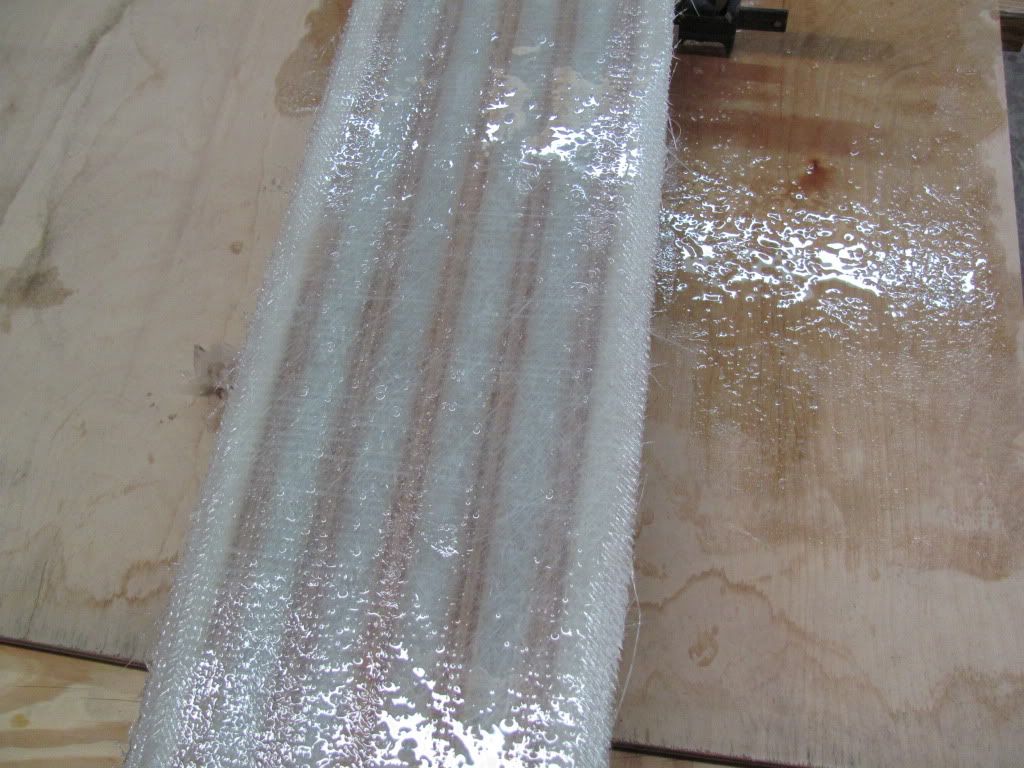

Since you are doubling the amount of stringers, there is no need to make them any thicker that the original 3/4". You will need to tab them in with 3 layers of 12 oz biax tape, then cover them completely over with two layers of heavy biax (1708), this is probably more glass than what was covering them previously. This assumption is based on the picture where it looks like the old stringers had only one layer of heavy roving. Do you have an actual measuemtn of the thickness of the glass on the side of the stringer?

What about the transom?

I can give an estimate on the amounts because we do not have measurements of the pieces (length/height).

You will need epoxy, wood flour, silica, 12 oz biax tape, and a heavy biax (1708 is a good choice). I can tell you that you will need the following to get started: 6 gallons epoxy, 5 lb. wood flour, 1 lb silica, 2 rolls biax tape, 10+ yards of 1708. That may be enough o get the new stringers in

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Aug 03, 2010 12:36 pm

by NOTHING ELSE MATTERS

Joel, can i fax you a sketch with the measurements ? My scanner gave up. (give me your fax #).Thanks.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Aug 03, 2010 1:12 pm

by tech_support

sure, 772-770-3249

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Aug 03, 2010 1:35 pm

by NOTHING ELSE MATTERS

Faxing to you now.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Aug 03, 2010 2:35 pm

by tech_support

got the fax, thank you. That is exactly the sort of info we need

I will take it home and respond tonight.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Aug 03, 2010 2:39 pm

by NOTHING ELSE MATTERS

shine wrote:got the fax, thank you. That is exactly the sort of info we need

I will take it home and respond tonight.

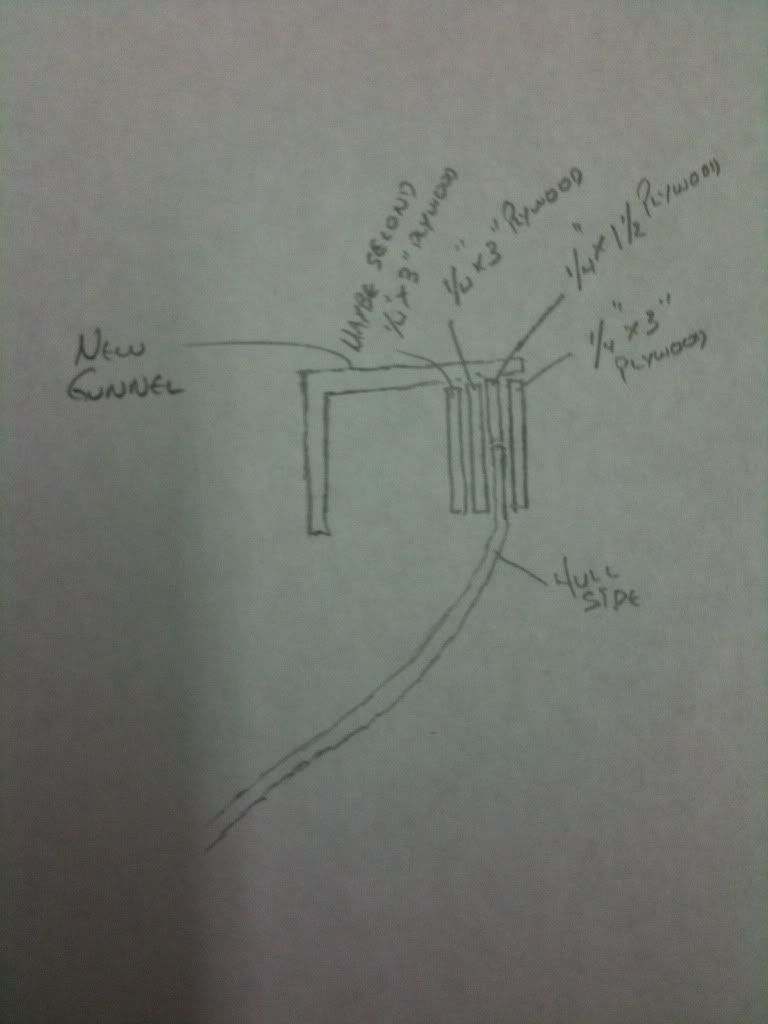

Thank you, you can post my artwork here if you like, i don't mind, just make sure they don't make fun of me of my drawing skills

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Aug 04, 2010 8:47 pm

by tech_support

I have not forgot, I promise to post first thing in the a.m.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 05, 2010 8:38 am

by NOTHING ELSE MATTERS

No problem, i understand you are a busy man.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 05, 2010 10:47 am

by tech_support

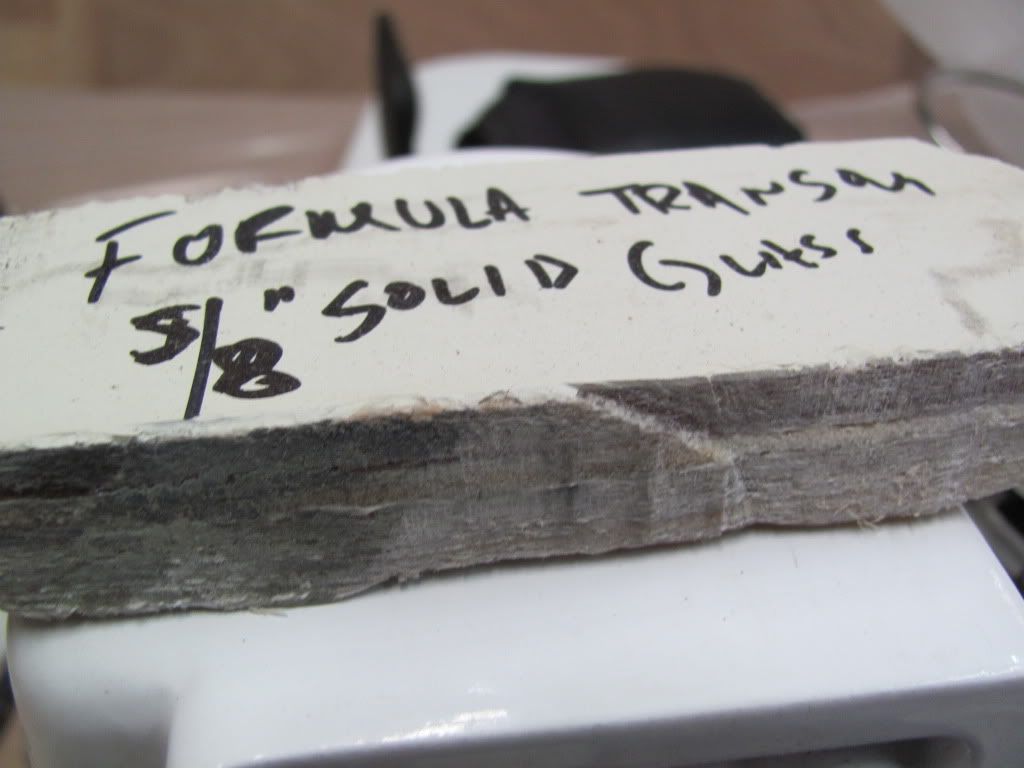

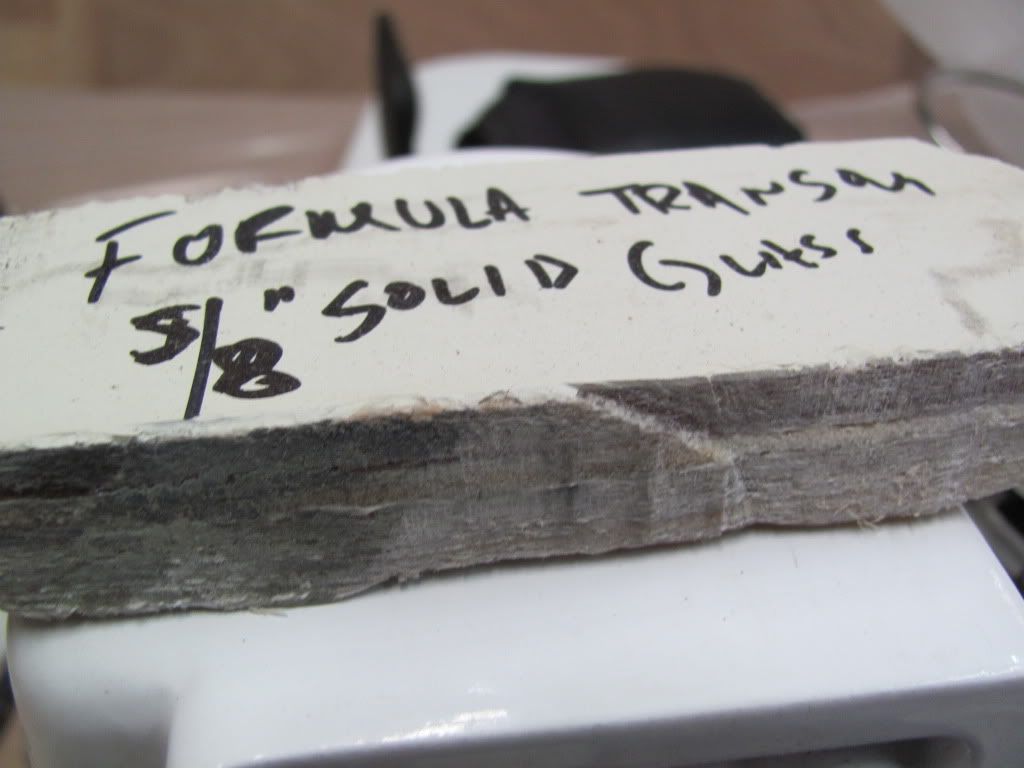

transom:

You mention outdrive needs 2.25" max. If outside skin is 1/4", then I would make my core 1.75" thick, then build the inside skin up until you reach the 2.25" You can do this a couple ways, 2 layers of 3/4" and one layer 1/4", or two layers 1/2" and one layer 3/4". I would go with the two layers of 1/2" and one layer of 3/4" because it will eave you will more usable scrap (1/2" scrap will be more useful than 1/4"). With three layers of glue (two between cores and one to the outside skin) you will probably only need 3/16" or so inside skin to reach 2.25" total.

grid structure:

what you propose in the sketch is very safe

For structural purposes you do not need those two most forward frames between the inside stringers, but there is no problem to include them for the purpose of dividing the compartments (anchor/porta potty)

Im pretty surprised there was not another stringer set in the original design, that is a large area from the stringer to the chine. Adding another is a good idea. 3/4" thickness for stringer plywood core. Locations on the sketch are good.

floor frames: you do not need that many, 30" between them is fine. The locations of the floor frames between the two stingers looks right, make the frames on the outside (between outside stringer and chine) at the same location, omit the the most forward frame on the very outside.

motorwell bulkhead: 3/4" is pretty thick, but it will not hurt. Is there a reason not to take the stringers all the way back tot he transom (interference with motor mounts maybe

)

stringers: tabbed in with 3 layers of 12 oz tape, covered with 1708 and overlapping the tabbing

frames: tabbed in 2 layers 12oz tape

An estimate based on the sketch:

12 oz biax tape: 3 rolls for stringers, 2 rolls for frames and the rest

1708: 13 yards for stringers, 13 yards for transom (4 layers including overlaps to side and bottom)

Epoxy: 15 gallons - maybe more depending on how much you use for filling gaps

wood flour: get at least 5 pounds to start

silica: 1 pound

you did not include any details about the new soul, but with such tight spacing of supports, 1/2" is plenty. If you use good wood you only need glass on the top side, 2-3 coats epoxy on the underside.

I think that should get you pretty far

I would start with the transom, then rip out the rest and build the grid. Mkae sure the boat is supported on bunks and blocks. Keep the pictures coming.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 05, 2010 11:10 am

by NOTHING ELSE MATTERS

Joel, thank you very much. I will follow what you are saying, the only thing i will do different is do the stringers first because i ripp them already and don't want to have the hull for too long with no stringers. The reason the stringers don't go all the way in the back is because there is not enough width for the motor(is only 27"), BUT, my next question to you would be if i could have my stringers 35" apart(this is how much i need for engine) and run them as one piece front to back.

Also, the plywood i' m using is meranti 1088BS. I was also thinking 1/2" for floor.

How do i go ahead and place the order with you? Can i also call you on the phone and speak to you?(i need the number)

Thank you again.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 05, 2010 12:41 pm

by tech_support

That is what I thought (space for motor), no problem.

Also, the main reason for doing the transom first is so that the stringers can come all the way back to the new transom skin - in your case this isnt happening anyway, so no problem doing the stringers (to the bulkhead) first.

You can either enter the order through the website, or you can call and we will enter it, its up to you. phone order line 772-770-1225, normally I answer the phone. If you have more technical questions, I prefer to answer them here so I can remember everything.

Re: 1981 FORMULA F233 RESTORATION

Posted: Sun Aug 08, 2010 10:13 pm

by NOTHING ELSE MATTERS

O.K gentlemen, stringers have been removed and grind down all the old tabbing. Between the tabbing and the place where the stringers were i still have a raised old tabbing of approximate 1/8".

1- What do i do with that space? Do i have to fill it in some epoxy filler? (new stringers go to the same spot)

2- After i sweep and vacuum all the fiberglass dust, what do i clean with the interior of the boat? I mean, do i use any chemicals like acetone or denaturated alcohol or anything else?

Re: 1981 FORMULA F233 RESTORATION

Posted: Sun Aug 08, 2010 10:26 pm

by Chief Brody

I had the same issue and I ground it down until the transition was totally smooth....no light spots or edges...just solid color

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Aug 09, 2010 1:09 am

by NOTHING ELSE MATTERS

Chief Brody wrote:I had the same issue and I ground it down until the transition was totally smooth....no light spots or edges...just solid color

I could grind it more, but i'm afraid going to grind the original floor and loose strength. I tried to peel it of with a crow bar to check the strength and it won't budge.

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Aug 09, 2010 10:02 am

by tech_support

its ideal to remove all tabbing, you want you stringers to be bonded (with epoxy) to the hull, not bonded to old tabbing. If the new stringers are bonded to the old tabbing your stringers are not bonded any better than the residual tabbing to hull bond.

I understand its almost impossible to get it all off, but try to get close

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Aug 09, 2010 10:46 am

by NOTHING ELSE MATTERS

So, what if i lay a layer of glass on the whole bottom on top of the old tabbing, then start building on top of that?

Also, the cleaning question, after i wipe and sweep the hull interior, do i clean the hull with any chemicals or just water?

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Aug 09, 2010 10:52 am

by tech_support

not as good as glassing stringers to hull, but it is better than nothing. How wide is this strip of old tabbing material?

Yes, wipe down areas before new glassing. I would use acetone or denatured alcohol

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Aug 09, 2010 10:53 am

by NOTHING ELSE MATTERS

shine wrote:not as good as glassing stringers to hull, but it is better than nothing. How wide is this strip of old tabbing material?

About 6" wide woven roven.

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Aug 09, 2010 11:10 am

by Chief Brody

After grinding smooth, I washed down all the dust with water.....let dry...then wipe down with solvent pror to glassing....I'm using denatured alcohol

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Aug 09, 2010 11:23 am

by NOTHING ELSE MATTERS

One more question.

Floor frames:

1-Do i bring them to touch the side of the boat of i have to leave a space?

2-Do i install them on the floor or i have to leave a space same as the stringers?

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Aug 09, 2010 11:28 am

by tech_support

NOTHING ELSE MATTERS wrote:One more question.

Floor frames:

1-Do i bring them to touch the side of the boat of i have to leave a space?

2-Do i install them on the floor or i have to leave a space same as the stringers?

Tiny gap all around is ideal, let the glass tabbing carry the loads

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Aug 10, 2010 10:50 pm

by NOTHING ELSE MATTERS

Joel, can i install the main stringers at 32" apart? I will install 3/4 flat plywood 4" wide as stiffeners under the tank.

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Aug 11, 2010 9:36 am

by tech_support

NOTHING ELSE MATTERS wrote:Joel, can i install the main stringers at 32" apart? I will install 3/4 flat plywood 4" wide as stiffeners under the tank.

Thats a wider span than original. What is the deadrise angle of the hull (midsection going aft)? Is there room for a 4" tall stringer under the tank, down the centerline?

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Aug 11, 2010 10:27 am

by NOTHING ELSE MATTERS

Joel, she is a 24* dead rise and yes, there is room, if you remember i was going to have a sub floor under the tank with a drain pipe by the keel and one stringer on each side 4-5" high. Also i was going to put 3/4" x 4" plywood stiffeners about 8" away from the length of the keel.

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Aug 11, 2010 11:02 am

by tech_support

Also i was going to put 3/4" x 4" plywood stiffeners about 8" away from the length of the keel.

no need for this if you glass that "sub floor" to the hull. If you glass that "subfloor" to the bottom, you have basically made a stringer. Also with 24 deadrise, the keel itself is a stringer. No problem moving the main stringers out to 32" apart, they will then only be 10" for the keel stringer structure (glassed in subfloor).

The span for your sole will now be wider, that only means you might need a stiffener of framing under the sole in this wide spot.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 12, 2010 12:30 am

by NOTHING ELSE MATTERS

Joel, got the shipment today, thank you very much. I'll be in OBX all next week, when i come back will start working on this old girl again, can't wait.

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Aug 25, 2010 11:12 pm

by NOTHING ELSE MATTERS

Question for the pros.

How much foam do i need on a 5000 lbs boat? I'm trying to figure out some storage compartments on my boat.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 26, 2010 8:40 am

by Cracker Larry

How much foam do i need on a 5000 lbs boat?

A lot

Foam supports 60 pounds per cubic foot, so that would be 83 cubic feet. A 2 gallon kit of foam makes 8 cubic feet, so you would need about 21 gallons of liquid.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 26, 2010 9:49 am

by NOTHING ELSE MATTERS

That's what i figure, 11 kits=5280 lbs, but that seems a lot of foam or maybe not, i never used this product before, so

With another words, in order for the boat to float if swammed, i have to have the amount of the boats weight same with foam buoyancy or more?

What i mean is that the boat weighs 5000 lbs, if filled with water weighs more, how much buoyancy do i need now?

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 26, 2010 9:52 am

by wadestep

Don't forget that the boat itself displaces water. It would be hard to calculate, but you can subtract the bouyancy of the boat from the extra flotation required. I'd bet this would cut down the amount of foam required significantly.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 26, 2010 9:56 am

by wadestep

NOTHING ELSE MATTERS wrote:That's what i figure, 11 kits=5280 lbs, but that seems a lot of foam or maybe not, i never used this product before, so

With another words, in order for the boat to float if swammed, i have to have the amount of the boats weight same with foam buoyancy or more?

What i mean is that the boat weighs 5000 lbs, if filled with water weighs more, how much buoyancy do i need now?

If your boat was infintessimly small, yet still weighed 5000 lbs (like a mini black hole) (impossible), then you would need 5000 of bouyancy. However, your requirement should be significantly less than that. I don't know how to figure this out without sinking the boat and then weighing it underwater. there must be another way...

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 26, 2010 10:01 am

by NOTHING ELSE MATTERS

wadestep wrote:NOTHING ELSE MATTERS wrote:That's what i figure, 11 kits=5280 lbs, but that seems a lot of foam or maybe not, i never used this product before, so

With another words, in order for the boat to float if swammed, i have to have the amount of the boats weight same with foam buoyancy or more?

What i mean is that the boat weighs 5000 lbs, if filled with water weighs more, how much buoyancy do i need now?

If your boat was infintessimly small, yet still weighed 5000 lbs (like a mini black hole) (impossible), then you would need 5000 of bouyancy. However, your requirement should be significantly less than that. I don't know how to figure this out without sinking the boat and then weighing it underwater. there must be another way...

Now you got me more confused. I know about the physics that what ever you put in the water looses as much weight as the weight of the water displaced, that is what i'm trying to understand.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 26, 2010 10:21 am

by tech_support

You do not need enough to displace 5000 pounds, but you do need enough (assuming you want positive flotation) to displace what the rest of the boat does not. The materials that make up the boat have a volume (wood/glass/gas/tanks/etc) that volume displaces water. So what you actaully need is enough buoyancy foam to float the difference between the boats weight and its submerged displacement. Now the problem

what is that volume of all the parts in the boat?

You cant answer that unless you have a very detailed spreadsheet or a 3D computer model. The easy way: assume the original designers did this calculation correctly when they deigned your boat, and they knew how much foam they needed to give positive flotation. So you can fill that same spaces they filled and have the same amount of buoyancy.

In your case, you are moving things around, but you can still measure the volume of the areas that used to have foam. I would replace that same volume, plus a little to be conservative.

All of this is just to say that you have to use 5,000 pounds of buoyancy

Of course it doesn't really hurt anything to use more foam.

In the case of your boat, they were using the foam to support the sole and stiffen up the hull - so you may find that they used more than they needed for just buoyancy

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 26, 2010 10:24 am

by Cracker Larry

Good point Wade. I started to bring that up initially, but don't know how to figure it either

so I just answered the question for 5000 pounds. A plywood boat has a lot of flotation from the wood itself. To figure it accurately you would have to know the specific gravity of each component in the boat. That's why we pay Jacques the big bucks, so he can tell us how much we need

Edit: I see Joel posted the same time I did. Sorry

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 26, 2010 12:13 pm

by NOTHING ELSE MATTERS

Thank you guys for your answers.

Now, because i don't want to high jack Larry thread, Shine, i read everything you post about my question on ratio for 1708 and i understand what you are saying, but if i really want to find out the ratio just for me to know that i'm applying enough resin(or i don't), how can i figure that out?

Also, for the sole, do i use the same 1708 you gave me and how many layers, or do i have to get 12oz biax?

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 26, 2010 12:24 pm

by tech_support

12 oz is good for the top of the sole, 1708 would be overkill for normal use

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Aug 26, 2010 1:49 pm

by Chief Brody

NOTHING ELSE MATTERS wrote:but if i really want to find out the ratio just for me to know that i'm applying enough resin(or i don't), how can i figure that out?

After cutting your fabric, you can weigh each piece and determine how much resin is required....if a section uses 5lbs of fabric, you'll need 5lbs of resin for a 50/50 glass to resin ratio. If you run short of resin, you know you're putting it on a little too heavy. This does not include what the wood core will soak up during pre-coat.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Aug 31, 2010 10:31 pm

by NOTHING ELSE MATTERS

One more question(out of thousands i have), my stringers are going to be 18' 3" long, they are 1/2" plywood doubled to make up one inch, what is the best way to join/divide in order to get the best performance out of them? Thank you.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Aug 31, 2010 11:34 pm

by TomW

The best way is to make them is so there is at least a 2' overlap between the seams of the two differerent sides of the stringer. You will need to make them out of 3 peices since they are over 16' long. So plan on making your seams 2' apart as you lay out the peices. Say start with a 6' peice on one an 8' peice on the other until you get the full length.

Re: 1981 FORMULA F233 RESTORATION

Posted: Sat Sep 04, 2010 10:33 pm

by NOTHING ELSE MATTERS

O.K, removed the rotted plywood from the transom, sand everything nice and smooth, what's next ?

Do i have to clean with alcohol the old fiberglass?

I was thinking of making the transom plywood first to the 1 3/4 thickness i want, then mix some resin with wood flour for glue.

Do i apply the glue to the boat transom AND the plywood, or just on one ? I know i have to coat the plywood with resin before in order to absorb some resin, do i have to wait for that resin to dry?

Re: 1981 FORMULA F233 RESTORATION

Posted: Sun Sep 05, 2010 9:33 am

by gk108

Do i have to clean with alcohol the old fiberglass?

Acetone would be the best solvent for cleaning. It will get any oily residue out of there.

I was thinking of making the transom plywood first to the 1 3/4 thickness i want,

You could, but things have a tendency to wander around a bit when assembling. With the way your boat is made with the small insert, it might be the most practical way.

Do i apply the glue to the boat transom AND the plywood, or just on one ?

Both sides. Use a notched spreader to apply the glue and you'll get a nice even glue joint if you apply clamping pressure evenly. No need to let that first coat of neat epoxy set up first, it will be better to go wet on wet as much as possible around your transom.

Re: 1981 FORMULA F233 RESTORATION

Posted: Sun Sep 05, 2010 11:55 pm

by NOTHING ELSE MATTERS

Thanks gk108.

I spend the whole day making a template for the transom then cut 3 pieces of plywood (1/2"-3/4"-1/2"), i coated the sides that were going to glue together with 3 coats of resin, then while was still tacky i made up some glue with wood flour and glue them together. I clamped them together and will leave them over night to cure( i was done gluing around 4 PM.

Question. I have some holes on the transom which i like to close, basically old screw holes. Do i have to apply a small piece of the 6" 12oz tape i have before i spread the glue or the glue it's self will plug those holes?

I really like to work with epoxy, never did before, i always used polyester, this stuff gives you a lot more working time and the resin spreads very good with the roller.

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Sep 06, 2010 12:48 am

by NOTHING ELSE MATTERS

shine wrote:NOTHING ELSE MATTERS wrote:One more question.

Floor frames:

1-Do i bring them to touch the side of the boat of i have to leave a space?

2-Do i install them on the floor or i have to leave a space same as the stringers?

Tiny gap all around is ideal, let the glass tabbing carry the loads

Joel, i'm a little confused. If i raise the stringers let's say 1/4", when i apply the fillets, do i squeeze the mix to go under the gap(do i have a hard spot this way?) or i just apply it at the edge on the stringer?

Also, Joel, i've been thinking of what you told me in the beginning and wanted to bring the stringers all the way to the transom. If i do that, i will have a span of 35" between the two inner stringers. The way i figured is that will have enough room for at least TWO 5" stringers by the keel and have the 1 1/4" drain pipe in the middle, then install a flat sub floor to be the floor where the tank will seat.

This is a "cut away" drawing so you know what i'm talking about

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Sep 06, 2010 8:59 am

by tech_support

what is the width of the part your calling the sub floor? The stringers underneath are not needed. Your boat has enough deadrise angle that the keel actually counts as a stringer

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Sep 06, 2010 12:50 pm

by NOTHING ELSE MATTERS

shine wrote:what is the width of the part your calling the sub floor? The stringers underneath are not needed. Your boat has enough deadrise angle that the keel actually counts as a stringer

Would be between 18" and 24"

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Sep 06, 2010 12:53 pm

by NOTHING ELSE MATTERS

NOTHING ELSE MATTERS wrote:

Question. I have some holes on the transom which i like to close, basically old screw holes. Do i have to apply a small piece of the 6" 12oz tape i have before i spread the glue or the glue it's self will plug those holes?

Anyone before is too late

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Sep 06, 2010 12:54 pm

by NOTHING ELSE MATTERS

shine wrote:what is the width of the part your calling the sub floor? The stringers underneath are not needed. Your boat has enough deadrise angle that the keel actually counts as a stringer

So you think is O.K to go with a spread of 35" on the stringers and all the way to the transom? I really like that idea better as it ties everything together much better.

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Sep 06, 2010 1:29 pm

by JamesT

as far as filling the holes...my opinion would be to just glue up the transom as is, then fill the holes with epoxy/fairing mix from the outside...just my two cents hope it helps. Looking good so far.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Sep 07, 2010 9:54 am

by tech_support

So you think is O.K to go with a spread of 35" on the stringers and all the way to the transom?

assuming you have that floor or small stringers down the middle, yes

Repair the holes from the outside after you have glued in the new core

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Sep 07, 2010 11:40 am

by NOTHING ELSE MATTERS

Joel, i'm a little confused. If i raise the stringers let's say 1/4", when i apply the fillets, do i squeeze the mix to go under the gap(do i have a hard spot this way?) or i just apply it at the edge on the stringer?

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Sep 07, 2010 11:43 am

by tech_support

What little squeezes under there will not create a hard spot

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Sep 08, 2010 1:00 am

by NOTHING ELSE MATTERS

I did some work yesterday, after i took out the clamps i dry fitted the transom plywood, then i marked for all the holes i need, i over drill them by double the size and filled with epoxy and wood flour.

Today i took a day off to run some honey do's.

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Sep 08, 2010 1:07 am

by NOTHING ELSE MATTERS

On a piece of core that i cut with the hole saw i noticed that i can't see the glue line between the three pieces of plywood. Is this normal ? I did a "field" test trying to get it apart with a hammer, but that was impossible.

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Sep 08, 2010 1:18 pm

by FitzFisher

I ran into the same thing when I did mine, but then I realized that I mixed up a bunch of glue/putty and very little squeezed out the sides when I clamped it together, so it has to be in there doing it's thing. So unless you ended up with massive globs of glue coming out when you clamped it together (and I doubt you did based on what I saw in your pictures), I wouldn't sweat it. You'll have a very solid piece when you are all done. Keep up the good work

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Sep 08, 2010 11:21 pm

by NOTHING ELSE MATTERS

The good thing is (i hope) that VERY little squeezed out from EVERYWHERE. Anyway i did another "hammer" test today with a heavy 24oz hammer, i waked it pretty hard, did not come apart. Sooooooooooooo, today i dry fit the plywood again, made all my holes to match the transom, coated two coats of epoxy, i will give one more tomorrow and then glue it to the skin.

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Sep 08, 2010 11:53 pm

by NOTHING ELSE MATTERS

Question for the pros/u]

I would like to make the new motor mounts

I know how to make them, my question is the section that sticks up about 2"-2 1/2" that the motor mount gets fasten is always a problem with the water going into the screw holes. I will not do the engine installation and most likely i will not be there to see if they will seal with 4200 or 5200, so, how can i make that piece to be totally waterproof ? The rest of the stringer/mount i will make it out of plywood.

What i was thinking was to make that little section(12"L x 3 1/2"W x 2 1/2"H) out of poured epoxy and wood flour, mold it around it of course. What you guys think or i'm open to ALL ideas.

BTW, this has to be quick  i'm doing them next.

i'm doing them next.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 09, 2010 8:08 am

by Cracker Larry

What i was thinking was to make that little section(12"L x 3 1/2"W x 2 1/2"H) out of poured epoxy and wood flour, mold it around it of course.

That would work fine and it wouldn't matter if some water got in there. I would add some chopped or milled glass fiber to the mix to give it a little more strength, or if you don't have any, just cut up some cloth scraps. Also, if it's warm where you are, pour the mold in 2 or 3 batches, not all at once, so it doesn't get too hot and boil the epoxy.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 09, 2010 9:23 am

by Chief Brody

You guys feel just epoxy putty in a 12x3.5x2.5 block will be strong enough to hold the engine mounts and torque action over time? I would lean more towards making a thickly stacked laminate out of small pieces of glass and glueing that in instead and taping it over....the glass should be what carries the load, no? Just thinking out loud....

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 09, 2010 10:08 am

by NOTHING ELSE MATTERS

Chief Brody wrote:You guys feel just epoxy putty in a 12x3.5x2.5 block will be strong enough to hold the engine mounts and torque action over time? I would lean more towards making a thickly stacked laminate out of small pieces of glass and glueing that in instead and taping it over....the glass should be what carries the load, no? Just thinking out loud....

After i'm done with the pour, i will wrap everything with at least 3 layers of 1708 and more where that motor mount is.

Chop glass is a good idea and i do have plenty of that.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 09, 2010 2:44 pm

by FitzFisher at Work

How about mounting a stud or something with a litle more purchase. Or Maybe even leave an access window in the block where a nut and washer could be fastened to the bolt that comes in from the top Make all the mount out of laminated plywood and wrap it all real good. Do the overdril, fill and drill method and you would have soemthing that would last forever.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 09, 2010 3:08 pm

by FitzFisher

Here is a diagram of my suggestion to address the motor mount. Could be completely encased plywood laminations for strength with the overdrill and fill method where the bolt goes through. Strong and watertight....what do you think dudes?

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 09, 2010 4:52 pm

by NOTHING ELSE MATTERS

The problem i have is that i don't know exactly where those bolts would be.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 09, 2010 9:23 pm

by FitzFisher

The problem i have is that i don't know exactly where those bolts would be.

I'm not sure what you mean. My diagram is a side view. It looks like you already have a similar pad setup on your stringer no?

If it is a matter of forward/aft position, you could do a slot setup to give you some adjustability. Otherwise you may have to take some measurements. It looks like you had two smaller bolts holding the mount down to the stringer pad and the main bolt going through the rubber block into the mount, so maybe you don't need as much holding power as I have shown. Depends on how much torque you expect and how much beating and banging the boat/engine will take. Just a thought....

Or you could modify the setup to include a stainless or aluminum block to adapt the mount to allow the through bolt setup. Someting like this..

Then again I have a tendencey to overengineer stuff....

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 09, 2010 9:45 pm

by Cracker Larry

You guys feel just epoxy putty in a 12x3.5x2.5 block will be strong enough to hold the engine mounts and torque action over time?

Not just epoxy, but with plenty of wood flour, some chopped glass, some scrap cloth, heck yeah it will carry the load

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 09, 2010 10:13 pm

by TomW

Yes agree with Larry, if you mix milled fibers, wood flour and fiberglass cloth it can hold about anything. Your going to want a fairly thick mix. I'd start off with 50% milled fiber by volume, they thicken some more with woodflour, and other thickeners mentioned. Your not going to be able to pour more than about 1/2" at a time until the epoxy sets other wise you may get an exothermic reaction and the epoxy will get way to hot.

Cost wise it may also be more beneficial to go with wood.

Tom

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 09, 2010 11:54 pm

by NOTHING ELSE MATTERS

O.K, what is milled fibers ? I was going to put everything else you mention, but you got me with the fiber thingie.

What about if i use pressure treated 2 X 4 for that little piece only?

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 12:13 am

by TomW

Milled fibers are chopped fiberglass that make a very strong mix. Often called "liquid fiberglass"

http://boatbuildercentral.com/proddetai ... =E_mil_2lb

Tom

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 7:56 am

by Cracker Larry

What about if i use pressure treated 2 X 4 for that little piece only?

No, epoxy doesn't bond well to PT lumber.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 9:22 am

by Chief Brody

Cracker Larry wrote:What about if i use pressure treated 2 X 4 for that little piece only?

No, epoxy doesn't bond well to PT lumber.

Man, I hope thats not 100% totally true CL.....at least not for PT XL Ply....except for a few areas, my whole project is pretty much using the PT plywood I got here.....the stuff at the local depot may be a little different though...probably a little higher moisture content which can make it harder to bond properly.

One thing you can do for the motor mount bolt holes is if you know what sized bolts they are, you can make some epoxy/fiberglass dowels that are oversized and pre-drill the bolt holes on the big dowels.....now when the boat yard installs the motor mounts, they can drill out the wood stringer oversize to match your pre-made dowel and epoxy it in.....now the wood core is protected and the boat yard can place the holes anywhere they need to.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 9:36 am

by tech_support

Resin will not bond well to pressure treated wood UNLESS the wood is dried out, then its fine. So you either buy kiln dried wood, or you wait for it tot dry and use a moisture meter to make sure its 12% or less (thats a rough figure)

The XL fir we stock is kiln dried.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 9:48 am

by Cracker Larry

I know I've got epoxy and glue and glass all over my PT building frames and picnic tables. After about a month it peels right off. It appears to be well bonded, but you can pull it off with your fingers. This is wood that's been in the sun for over 10 years.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 10:01 am

by tech_support

then dont build any boats with that wood

Could be a lot of things keeping it from sticking, could be it too slick, or the beams could be thick enough that the treatment hasnet dried out after 10 years - quite possible.

For those wondering, one can always do a test on any wood you are concerned about. Glue two pieces together, then rip it apart. If it peels off without tearing wood from wood then its failed (what Larry describes on those beams for example). If the bond of the epoxy is stronger to the wood than the internal strength of the wood, then thats all you need to know. Its a success when the epoxy rips up the first veneer of the plywood.

I have bonded a few pieces of the XL fir (kiln dried pressure treated) and the wood fails before the epoxy bond

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 10:03 am

by Chief Brody

shine wrote:Resin will bond well to pressure treated wood UNLESS the wood is dried out, then its fine. So you either buy kiln dried wood, or you wait for it tot dry and use a moisture meter to make sure its 12% or less (thats a rough figure)

The XL fir we stock is kiln dried.

Joel, will or won't bond well to PT wood unless its dried out...

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 10:06 am

by tech_support

sorry, forgot the "not"

Epoxy will NOT bond to pressure treated unless its dried out. Kiln dried mean we know it dry, aged means it may be dry (unless you have moisture meter). You can always test the bond as I describe above

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 10:26 am

by Cracker Larry

Just to show I'm not crazy (well, not about this anyway

), I went out and took a couple of pics.

This is epoxy and woodflour glue, spilled on PT picnic table. You can see the wood isn't slick at all, nor is it wet. It wasn't wet when the glue was spilled. I've done this dozens of times

The first few months it seems to be bonded solid as a rock, then it eventually comes unglued. Not just this table, but all my PT wood acts the same way. Leave it alone for a couple of months and it comes right off

Glue blobs on table...

Glue blobs pulled off with my fingers...

So, there ain't no way I'm going to use it on my boats. Yall can do what you want with yours

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 10:35 am

by gk108

I've used ½" PT plywood on a rebuild, but...

It was wet and warped when I bought it. I stored it for 4 months in the back of an old school bus, flat stacked and well ventilated and HOT in the Ga. sun. After that, it was well dried out and not warped. In use, every bit of each cut part was sanded before any epoxy was applied.

With all of that, it was still CD grade pine plywood, so it all had to be filled and sheathed in glass to make it durable.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 10:59 am

by Cracker Larry

I just pulled a piece of 2X6 out of my scrap pile, it was left over from the building frame of my GF16, had a lot of epoxy spills. This epoxy has been set on this lumber for 5 years.

Just using my fingernail I was able to peel it right off. There is no bond at all between the epoxy and the wood.

You could have never pulled it off in the first month or so, but wait a few months and it will fall off. If you're going to do a test, I'd recommend plenty of time, not an overnight test

I wish it would behave the same way on my concrete floor

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 12:47 pm

by FitzFisher

Yeah it's funny what this stuff will stick too and not. I saved a big piece of glass to work as a wet out table and figured it would just peel off when dried. I tried to scrape a piece off the other day and it pulled glass up with it...easier to break the glass T han the bond..

But back to his dilemma. Seems like the epoxy filler bed would be a good option as long as you follow the guidelines herein and use a good grade coarse lag bolt to attach the mounts into the epoxy bed after predrilling to prevent cracking. Once it is down it should not have enough raw torque to just pull out as long as it remains snug and isn't banging around or vibrating excessively.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 2:08 pm

by Chief Brody

NEM, sorry for derailing the thread a little, but it kind of goes hand in hand with what you're trying to do with PT lumber.

Cracker Larry wrote:I just pulled a piece of 2X6 out of my scrap pile, it was left over from the building frame of my GF16, had a lot of epoxy spills. This epoxy has been set on this lumber for 5 years.

Just using my fingernail I was able to peel it right off. There is no bond at all between the epoxy and the wood.

You could have never pulled it off in the first month or so, but wait a few months and it will fall off. If you're going to do a test, I'd recommend plenty of time, not an overnight test

I wish it would behave the same way on my concrete floor

CL.....I have the same scenario with some lumber and a wooden step ladder that I'm using to get in and out of the boat.....the globs of epoxy did pop off in spots like you said, but I think the reason is two-fold.....1) the epoxy has been exposed to UV over time outside...once it turns from a clear amber to a more muddy color, with or without filler, she's pretty much done. 2) when using the wood for building or repair, you normally encapsulate the entire surface and seal excess moisture out...my ladder, as with your table and lumber was open to air and moisture and continued to breath allowing moisture to get behind the epoxy and lose the bond.....on my boat, even with factory polyester resin....anywhere the wood was completely encapsulated, the bond from the factory was still good...anywhere they cheated or had poor workmanship and left areas open to moist air, the skins popped off with my hand once they got started.....I don't know if this theory holds water,

but I hope it does or I just wasted a lot of time and money...

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 5:05 pm

by Cracker Larry

I think your theory is sound Chief, at least to some extent, but I can show you epoxy on non-PT lumber that's been exposed to the weather and it still has a good bond. My boats stay outside and have constant weather exposure too. I've only personally seen this happen with PT lumber, specifically only on Southern Yellow Pine. I have no experience with the plywood you've used, and I'm sure that if it came from Joel, it will work perfectly as advertised. Didn't mean to shake you up

But based on my experience with it I thought I should caution against using it for motor mounts when there are better options available.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 11:28 pm

by NOTHING ELSE MATTERS

O.K, i'm sold, NO PT for me, thanks.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Sep 10, 2010 11:32 pm

by NOTHING ELSE MATTERS

TomW wrote:Yes agree with Larry, if you mix milled fibers, wood flour and fiberglass cloth it can hold about anything. Your going to want a fairly thick mix. I'd start off with 50% milled fiber by volume, they thicken some more with woodflour, and other thickeners mentioned. Your not going to be able to pour more than about 1/2" at a time until the epoxy sets other wise you may get an exothermic reaction and the epoxy will get way to hot.

Cost wise it may also be more beneficial to go with wood.

Tom

What happens when the epoxy gets too hot? Is it really bad for the mix?

Re: 1981 FORMULA F233 RESTORATION

Posted: Sat Sep 11, 2010 1:38 am

by TomW

It gets so hot it can literally weaken the fiberglass fibers. Any of us that have worked with epoxy can tell you of at least one batch that we had go off and literally start smoking on us.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Sep 21, 2010 12:27 am

by NOTHING ELSE MATTERS

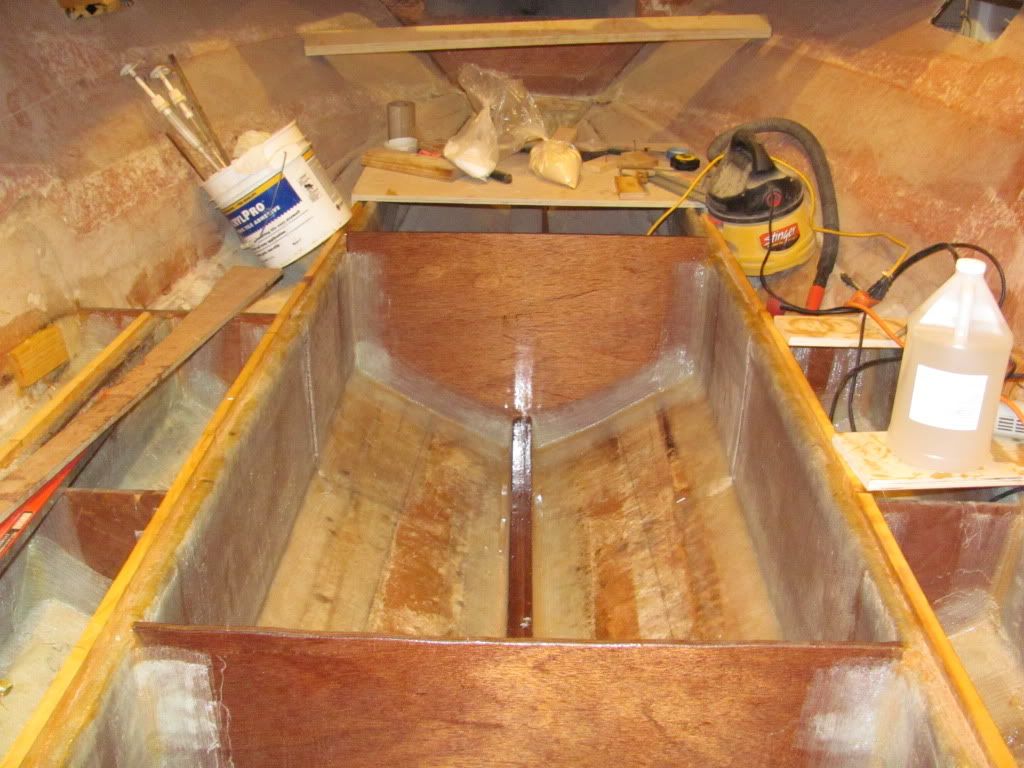

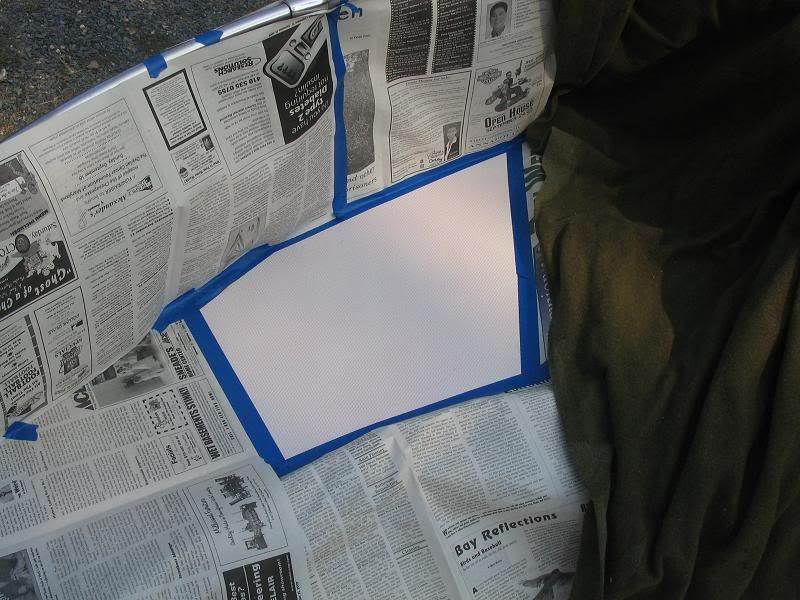

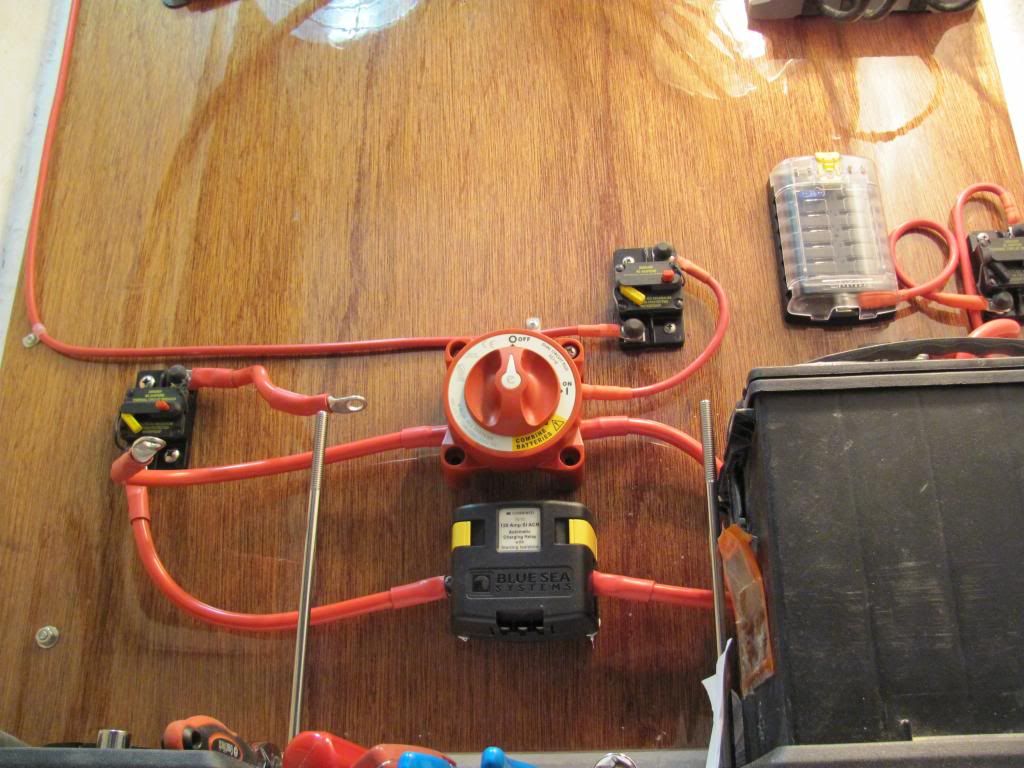

I've been doing some work on the Formula here and there, i wish i could work every day on her though. Anyway, i installed the plywood core for the transom

Then i decide to make the motor mounts out of layers of plywood, then overdrill where the studs will go and fill it with epoxy, wood flour and some chopped mat.

Built also a stand/holder for my roll of 1708

Here is a picture of the core installed, tabbed and glassed.

I have a question though, what and why do i have those white spots on the transom core? They are not bubbles.

I did get some bubbles on the floor where i made some turns and where the original floor was not smooth and i did not grind it down before, but i grind those bubbles, filled them and re glass over them.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Sep 21, 2010 2:15 pm

by Fitz at Work

Those are places where the glass is not quite saturated or where there are very tiny air bubbles in the layers or at the surface of the bond with the wood. You can avoid that in the future with a little more work on the Hard roller or squeegee and a little more resin in between your layers. THose are not a big deal from what I can see, but you will be able to avoid them in the future by working the area a little more.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Sep 21, 2010 3:57 pm

by NOTHING ELSE MATTERS

HELP, anybody ????

Shine, are you out there?

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Sep 21, 2010 4:07 pm

by tech_support

White spots are resin starved. While not ideal, I dont see anything that needs to be fixed (with the exception of the edges). Did you take the last picture after sanding?

Did you sand the biax tape before the 1708? If you do not sand off the stitching, it will keep the 1708 for laying out perfect.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Sep 21, 2010 10:48 pm

by NOTHING ELSE MATTERS

I did sand the edges but i did not go crazy, i was afraid i was going to remove a lot material.

When you say about the edges, do i have to do anything now at this point?

Last picture was taken after a day i finished the glass. I did not sand afterwards(if that is what you mean).

You said that white spots is starvation of resin, when i wet out the 1708 i had the mat side up, roll resin on it until the other side had changed color, i did not apply too much on the plywood, what i did was wet out the plywood until dark brown, then went and wet out the 1708, waited a few minutes, then wet out the plywood again(lightly, maybe this was my mistake), then install the 1708 on the plywood, roll it with the grooved roller to get the bubbles out and to lay it as flat as possible, then pushed some more resin with the 2" chip brass, then roll again. What did i do wrong here?

BTW, after the regular tabbing(the tape you gave me), i tabbed the bottom section with 1708 to make it "stronger"

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Sep 22, 2010 9:49 am

by Chief Brody

Looks like the wood end grain soaked up a liitle more than expected before the epoxy cured up. Maybe need to let it tack up a little before laying any glass. If I'm not mistaken, it looks like the wood is standing a little proud around the perimeter....maybe the 1708 had a hard time making the bend over the edge if it wasn't rounded over?? Just a thought.

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Sep 22, 2010 9:55 am

by tech_support

to avoid the white spots you just need to use more epoxy.

1708 needs a pretty generous radius to make turn and not "pop up".

If you have any true air pockets, where there is clearly an air bubble under the glass, then you will need to cut/grind it out

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Sep 22, 2010 3:39 pm

by NOTHING ELSE MATTERS

I made 3/8" radius all around except the bottom.

No, i don't have any air pockets on the wood( i can tell when i tap on it).

So, i should be good to go ?

So i know for the stringers, how can i tell that i have good amount of resin on the 1708 and on the wood?

Thanks guys, i never used 1708 before.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 23, 2010 9:32 am

by tech_support

You can proceed, but you need to sand the prior layer before putting on more. Its the stitching that keeps you fomr getting it to lay smooth (even if you did use enough epoxy). If the prior layer is cured/hard, you must sand it briefly of the next layers will look dry

Re: 1981 FORMULA F233 RESTORATION

Posted: Sun Sep 26, 2010 10:27 pm

by NOTHING ELSE MATTERS

shine wrote:You can proceed, but you need to sand the prior layer before putting on more. Its the stitching that keeps you fomr getting it to lay smooth (even if you did use enough epoxy). If the prior layer is cured/hard, you must sand it briefly of the next layers will look dry

Should i sand with 120 grit ? Or, better yet, what grit should i use ?

Re: 1981 FORMULA F233 RESTORATION

Posted: Sun Sep 26, 2010 10:38 pm

by NOTHING ELSE MATTERS

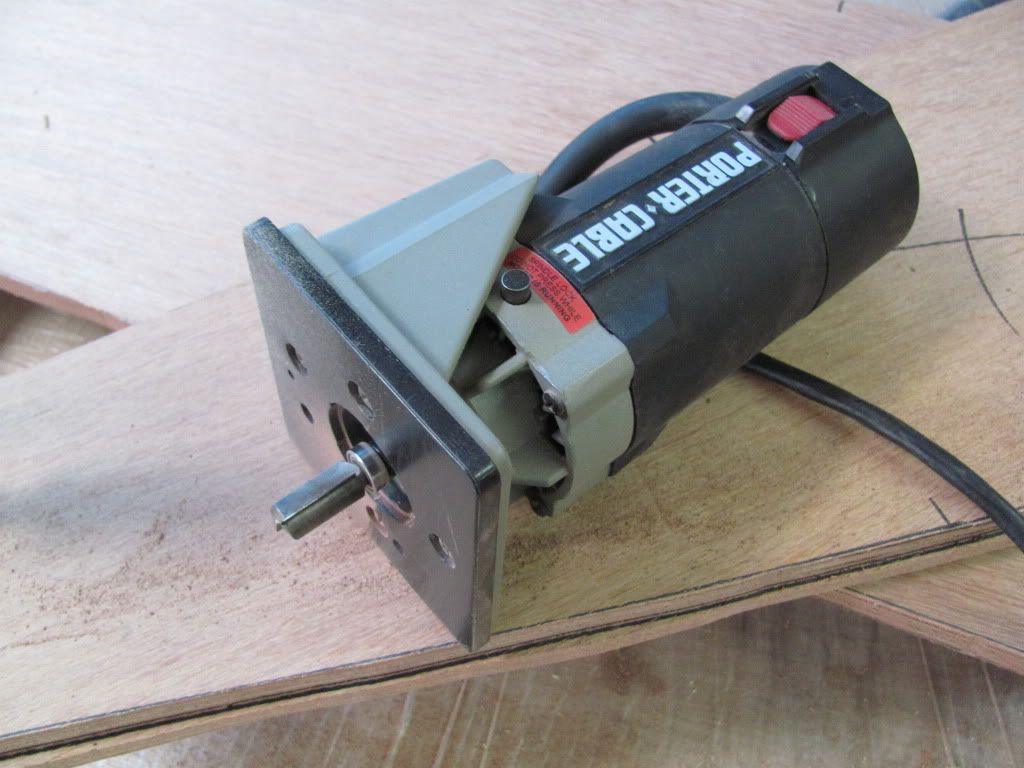

One more question for shine and the rest of the pros. I am ready to install the stringers the next couple of days. My stringers are 1" thick and i am using a 3/8" round over bit to smooth the top edges for the 1708. My question is can i bring the 1708 all the way up to the stringer, let's say 1/2" shy, then use 2-3 layers of 6" 12 oz tape to cap the stringers? The reason i am asking is i am afraid that the 3/8" round is not big/wide enough to have a smooth transition and i might end up with the 1708 not sticking and have a very long bubble at the top edge. The way i was going to glass the stringer is 50" at the time.

Also, how many layers of 1708 on the stringers ? I was thinking two of them.

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Sep 27, 2010 1:41 am

by FitzFisher

Lots of Questions but let's see if I can help.

120 grit is a little fine. Rougher is better, but you don't have to take a lot off, just knock of the high spots from the stiching.

The 3/8 round should be OK, but a good tip on getting the sutff to hold down on the corners is to get some heavy grade food/plastic wrap and pull it down across the top after you lay the glass and work out the bubbles down the sides. You can smooth all the remaining air out and keep it tight against the wood while it cures and then just peel it off after it cures up good. Tat way you can do it in one big 50" wide piece up one side and down the other. Worked great on mine. just make sure you have a decent amount of resin in on the wood and mat side and you'll be fine.

I only used 12oz to cover my stringers and was told that was plenty. Only one layer was used. , but my stringers are 1.5 thick so maybe you are relying on more glass for strength. That is a Jaques/Shine question, but it sure seems like one layer of 1708 with the tabbing should be plenty.

Hope this helps. I ahve become a big fan of the plastic wrap on the stuff I have been doing lately. Check out my post and see how it help me keep the glass down on some 3/4 plywood with lots of curves.

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Sep 27, 2010 2:07 am

by NOTHING ELSE MATTERS

Fitz, thank you for the shrink wrap trick.

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Sep 27, 2010 9:49 am

by tech_support

I use 60, you could even use a grinder (but thats risky), it should take about 1 second per foot to sand, you only taking odd the stitching.

Here is a picture of the tops of stringers being wrapped with plastic, you can really squeeze the air out doign this. The picture is a "cap" of carbon fiber, but the principle is the same for the biax.

wet out carbon (its saturated with epoxy, but you can tell because its black

)

plastic pressed over top

result

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Sep 27, 2010 10:02 am

by NOTHING ELSE MATTERS

Shine, how many layers of 1708 on the stringers?

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Sep 29, 2010 10:56 am

by NOTHING ELSE MATTERS

NOTHING ELSE MATTERS wrote:Shine, how many layers of 1708 on the stringers?

??????

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Sep 29, 2010 11:00 am

by NOTHING ELSE MATTERS

I am getting ready to install the stringers. I am lifting them off the bottom of the hull by 1/2" to 3/4", what do i do with that space, what i mean is when i start filleting all the glue (PB) will go under it, is it a trick to do in order to prevent this?

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Sep 29, 2010 11:13 am

by tech_support

NOTHING ELSE MATTERS wrote:Shine, how many layers of 1708 on the stringers?

have we not discussed that? I can read back, but I'm sure we have done this before, more than once.

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Sep 29, 2010 11:16 am

by tech_support

NOTHING ELSE MATTERS wrote:I am getting ready to install the stringers. I am lifting them off the bottom of the hull by 1/2" to 3/4", what do i do with that space, what i mean is when i start filleting all the glue (PB) will go under it, is it a trick to do in order to prevent this?

dont lift them that much, thats asking for a big mess

all you need is a slight gap, the thickness of a mixing stick is fine, max 1/4". Then you squeeze the fillet materiel under as much as you can. You dont have to go crazy getting the putty 100% under there.

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Sep 29, 2010 11:16 pm

by NOTHING ELSE MATTERS

shine wrote:NOTHING ELSE MATTERS wrote:Shine, how many layers of 1708 on the stringers?

have we not discussed that? I can read back, but I'm sure we have done this before, more than once.

Originally you had told me two layers of 1708 on each stringer but that was when i was going to install only two stringers as it was original, now i am going with this version

Do i still have to put two layers of 1708 on all stringers?

Thanks.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 30, 2010 10:57 am

by tech_support

OK, with 4 stringers spaced as in your drawing, with 1" thick stringer. 1 layer overlapping to 6" on the bottom, thats after 3 layers 12 oz tape tabbing on each side

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 30, 2010 11:21 am

by NOTHING ELSE MATTERS

Thanks Joel.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 30, 2010 11:40 am

by tech_support

NOTHING ELSE MATTERS wrote:Thanks Joel.

Your very welcome

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 30, 2010 3:19 pm

by NOTHING ELSE MATTERS

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 30, 2010 3:51 pm

by tech_support

nice spacers

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 30, 2010 9:55 pm

by FitzFisher

Looking Good Mon. Your coach is keeping you moving in the right direction. He is a good looking dude.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 30, 2010 11:21 pm

by Dumb Axe

You didnt happen to buy that 77 Formula I put on here did you? That thing sat there for years and now it is gone so thought maybe you came and got it.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 30, 2010 11:51 pm

by NOTHING ELSE MATTERS

Dumb Axe wrote:You didnt happen to buy that 77 Formula I put on here did you? That thing sat there for years and now it is gone so thought maybe you came and got it.

No, this is a 1981, but i am interested on the one you saw also.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Sep 30, 2010 11:55 pm

by NOTHING ELSE MATTERS

FitzFisher wrote:Looking Good Mon. Your coach is keeping you moving in the right direction. He is a good looking dude.

Thanks Fitz, he is the best dog i ever had but a little stubborn.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Oct 01, 2010 11:18 pm

by Dumb Axe

I put the guys phone number on that other post. Somebody worked on the trailer this week and then it was gone. Not sure if he sold it or took it somewhere else. I am just glad it is moved it was tempting me.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Oct 15, 2010 12:43 am

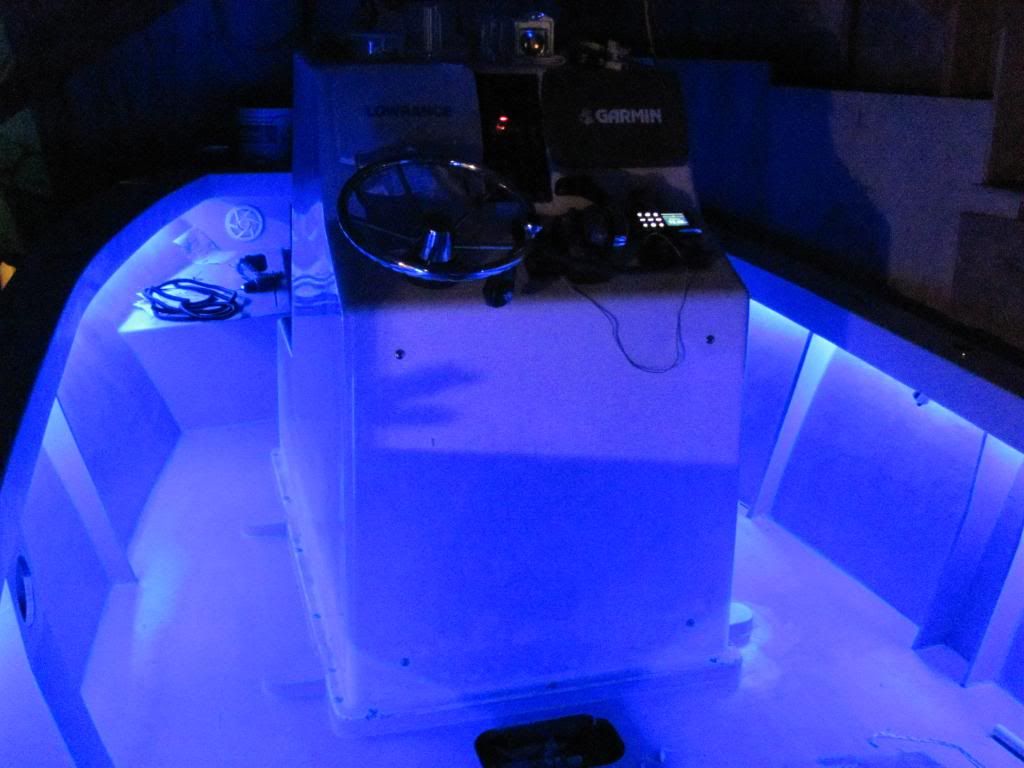

by NOTHING ELSE MATTERS

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Oct 15, 2010 10:46 am

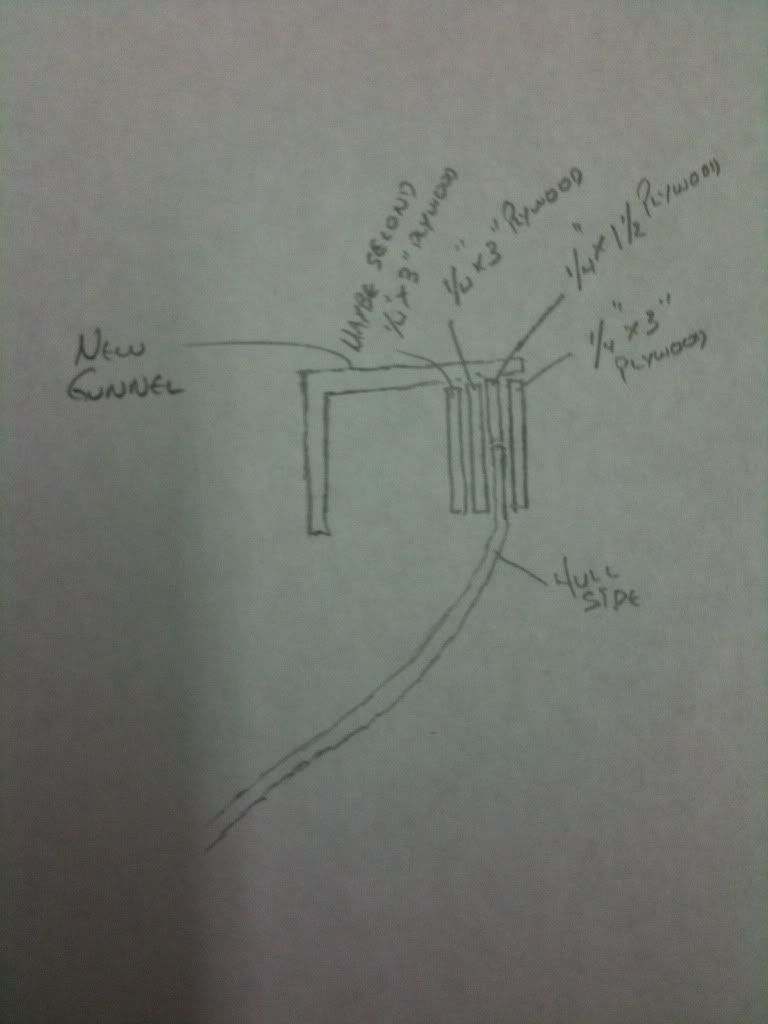

by Chief Brody

NEM, the work looks pretty good!!! That second "doner" boat looks to be in good shape....you're pullin' that motor and tossing "raising hell"? Must have been a really good deal. Will you need to do anything structurally by converting her to a center console? Any additional support to keep the gunwales in shape?

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Oct 15, 2010 11:48 am

by NOTHING ELSE MATTERS

Chief Brody wrote:NEM, the work looks pretty good!!! That second "doner" boat looks to be in good shape....you're pullin' that motor and tossing "raising hell"? Must have been a really good deal. Will you need to do anything structurally by converting her to a center console? Any additional support to keep the gunwales in shape?

The way i' m building under the sole it will be bulletproof. As far as the sides i will be installing plywood pieces perpendicular to the sides of the boat as support and also to be used as rod holders and a toe space on the bottom. For the front i will be building either a casting platform with storage and drain overboard or forward seating type (one long bench on each side) also with storage and drain overboard.

As far as "raising hell", yes, it was a great deal with a rebuilt outdrive in the front cabin as an extra bonus(long story), the boat i am throwing away(unless anybody here wants a free 22' Baja 1986(i think, i don't remember) and the trailer has no papers but i sold it for 350 bucks to a marina.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Oct 15, 2010 12:11 pm

by FitzFisher

Yeah that is looking good. Looks alot like mine on the inside, so you could probably do the casting deck as it was designed in mine too. I am in the process of putting that in right now and should have some pretty good pictures up soon. Basically the bulkhead across the front of the stringers goes up another 6 inches and the foredeck will sit on a combination of cleats, the top of the bulkhead and the lip of the fishbox. I just have to figure out how to attach cleats to the forward vee section that really doesnt have any support under it to rest them on. I'm headed to my post to ask that question now. Keep up the good work!

Re: 1981 FORMULA F233 RESTORATION

Posted: Sun Oct 17, 2010 9:03 pm

by Chief Brody

http://www.thehulltruth.com/boating-for ... -info.html

NEM...thought you'd be interested in another 233 rebuild....interesting to say the least....

Re: 1981 FORMULA F233 RESTORATION

Posted: Sun Oct 17, 2010 10:43 pm

by NOTHING ELSE MATTERS

WOW, thanks a lot.

That is a lot of work.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Dec 03, 2010 12:40 pm

by NOTHING ELSE MATTERS

Guys, question. I still have some glassing to do and temps here are at 40's. What can i do to raise the temp in the boat? The boat sits under a car port with tarp all around the boat. Is it safe to use a propane heater while glassing (epoxy) or should i use a heat lamp? Heat lamp would heat just the space i'm working on, while propane heater will heat the whole area.

This is the heater i would like to use

http://www.northerntool.com/shop/tools/ ... %2Bheaters

Also, after the glassing i have to install the foam, what do i do for heat for that task?

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Dec 03, 2010 1:09 pm

by tech_support

Epoxy needs at least 45-50 degrees before it will start to cure. You can keep the epoxy inside, then keep it under the heat lamp while your working. This way the epoxy itself is warm, so the reaction starts and hopefully tacks up quickly.

The foam is easy, just make sure the cans are warm, it will expand quickly. After expansion it doesn't matter what temp the air is.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Dec 03, 2010 2:11 pm

by Chief Brody

the only problem with any fuel type heaters is CO buildup inside your enclosed area. I did that in my garage for a few weeks in really cold weather one time. After keeping the garage warm for a few days, my CO monitor started going off in the basement as its attached to the garage with a door that was constantly opened. I was using one of those tube type 35,000 BTU heaters. I would opt for some type of electric heater instead since you're working inside the area. Those oil filled electric radiators ($50), while bulky, put out some good BTU's safetly.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Dec 03, 2010 4:00 pm

by NOTHING ELSE MATTERS

Chief, the tarp on the sides passes the gunnels by maybe a foot below and at least a foot away from the gunnels, so ( i think) i have a good circulation of fresh air, i could also use the box fan i had summer time on low speed for circulation. No?

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Dec 03, 2010 4:03 pm

by NOTHING ELSE MATTERS

Shine, when you say "worm" for the foam, how much warm? What i did the resin, i filled half a bucket of hot water from the sink and had my gallon of resin there to keep it warm and pour and mix for the rest 2-3 hours, it was like 55 degrees out that day though.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Dec 03, 2010 4:45 pm

by Cracker Larry

You'll get the best expansion from the foam if it's 90-100 degrees. As long as the mixture is warm it doesn't matter much what the outside temp is. Most of the expansion takes place within a minute or 2 of mixing.

Re: 1981 FORMULA F233 RESTORATION

Posted: Fri Dec 03, 2010 5:02 pm

by Chief Brody

as long as you keep a fresh supply of oxygen around, you won't deplete the ratio at the burner, so you should get complete combustion...it's when the burner is using the same air over and over that the % of oxygen in the air gets lower and lower and results in excess CO, incomplete.

Re: 1981 FORMULA F233 RESTORATION

Posted: Sat Jan 01, 2011 7:27 pm

by NOTHING ELSE MATTERS

Well, the last snow storm we had did a number on my boat cover, simply the whole canopy collapsed and snow went inside the boat and started to melt. Water sat at the bottom of the boat (by the keel) where is still the original polyester resin. Should i worry about absorbing water? Do i have a huge problem? As you know, the boat has no floor yet and just finished the transom and stringers( a month or so ago).

Re: 1981 FORMULA F233 RESTORATION

Posted: Sun Jan 02, 2011 7:27 am

by gk108

I don't think the moisture will do any permanent damage. Just dry it out good before you proceed. If any uncoated wood on the new stringers got wet, it may take up to a week or more to get that dried out again, but polyester hull and coated wood should dry out in a day or two of warm dry air exposure. The tent over my D15 build collapsed during a thunderstorm and made a big funnel that drained into my uncoated hull. It looked OK after drying a week, but I let it go for another week, just to be safe. I guess that was long enough, since there are no issues with paint or resin adhesion, etc.

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Jan 03, 2011 1:06 pm

by NOTHING ELSE MATTERS

gk108 wrote:I don't think the moisture will do any permanent damage. Just dry it out good before you proceed. If any uncoated wood on the new stringers got wet, it may take up to a week or more to get that dried out again, but polyester hull and coated wood should dry out in a day or two of warm dry air exposure. The tent over my D15 build collapsed during a thunderstorm and made a big funnel that drained into my uncoated hull. It looked OK after drying a week, but I let it go for another week, just to be safe. I guess that was long enough, since there are no issues with paint or resin adhesion, etc.

Thanks gk, yes, all wood is coated so no worries there, just the old polyester i was worry about. Can i put like a small heater in there and dry it that way?

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Jan 31, 2011 9:54 pm

by NOTHING ELSE MATTERS

Shine and the pros: I found another Formula center console which i really want to get and restore her too(when done with this one). What i wanted to do is replace the transom and close the hole from the I/O outdrive and use a single 250-300 outboard but NOT on a bracket. Can i cut the transom to accept a 30" shaft length outboard and then built one box on each transom corner so i will not have any flexing back there and a gate between them? Reason for the 30" transom is to have as much as transom i can above the water. For picture references you can use the pictures i have from the other Formula in this thread, boats are identical.

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Jan 31, 2011 10:25 pm

by TomW

Sure it would be similar to what you have done to date. Replace the transom with a peice that is 30" tall and then build the motorwell frames the distance for out from the transom for the proper disance for that size motor. AYBC has standards set for motors and Joel or Jacques can give you that measurement.

It will mean taking out more of the deck and stringers and tying everything new into the hull out about 20" or maybe a little more or less, but it's doable, by all means.

Re: 1981 FORMULA F233 RESTORATION

Posted: Mon Jan 31, 2011 11:23 pm

by NOTHING ELSE MATTERS

Tom, thanks for the quick reply. The boat will need new stringers and deck, so no problems there, my main concern is that the plywood at the transom does NOT go across the width of the transom, i know i will have to install knees but is that enough or after i am done with the transom, install another sheet of plywood over the transom plywood and the rest of the transom which is 1/4" solid glass ?

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Feb 01, 2011 9:02 am

by TomW

NEM the big problem is the bump out that they did for the outdrive.

That makes it hard to tie a new transom wood to the old outside fiberglass shell. One way to do it would be to build the wood up and fill in the hump so that you could then add full sized sheets of ply to get your proper transom thickness of 2 1/4" or so for a 300HP.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Feb 01, 2011 12:57 pm

by Chief Brody

And it looks like the bump out has a curve to it as well.....wonder if you'd be better off making a new transom like Joels Aquasport rebuild......start with a clean sheet.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Feb 01, 2011 3:20 pm

by NOTHING ELSE MATTERS

Chief Brody wrote:And it looks like the bump out has a curve to it as well.....wonder if you'd be better off making a new transom like Joels Aquasport rebuild......start with a clean sheet.

Chief, on the one i did all ready, after i was done with the 1 3/4 plywood and 5 layers of 1708 on the inside i end up even with the inside of the transom, i could fill the gap that the bump out creates and then go with a full sheet. What i really asking if i HAVE to do that or the existed bump out transom with 1 3/4 plywood and overall thickness of 2 1/4 is enough for a single 4S 300 outboard.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Feb 01, 2011 4:11 pm

by Chief Brody

right..understood.....I was looking more at how you would mount the outboard on a curved section of the transom and not use some type of bracket with gap filling ability....maybe I'm missing on how the motor will be hung on there flush.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Feb 01, 2011 6:12 pm

by TomW

The other problem that I see is the classic straight transom to the angled transom. An outdrive can use a straight transom, while an outboard needs a slanted transom of at least 6-8 degrees. Most builders use 11-13 degrees to ensure that any forward protruding objects don't hit the transom.

Another option NEM is to remove the bump out by cutting it out, then grinding it smooth on the edges. After that you would fill in the gap with 1708 and 1700 over lapping the edges so that you would have the strength and thickness you need to get what is already there on either side. Shine can help you there on overlaps and fill layers.

Good luck you have a great old boat and it's interesting to follow.

Re: 1981 FORMULA F233 RESTORATION

Posted: Tue Feb 01, 2011 8:38 pm

by NOTHING ELSE MATTERS

O.K, i went and measured the angle of the transom and is 11*. Does that mean i can't mount an outboard on a transom with that angle?

Also, the bump out section of the transom is flat and is NOT curved.

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Feb 02, 2011 8:15 am

by TomW

NOTHING ELSE MATTERS wrote:O.K, i went and measured the angle of the transom and is 11*. Does that mean i can't mount an outboard on a transom with that angle?

Also, the bump out section of the transom is flat and is NOT curved.

That makes sense NEM and no problem at all in mounting an outboard, that's a normal angle. Let's begin by removing the bump out so we have the same angle all the way across. That leaves a wide area to attach the new transom boards to and then to build up the outside hull area to match the current hull area.

The new transom boards will be be 2-2 1/4" plus fiberglassing to handle a 300HP enginel

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Feb 02, 2011 2:41 pm

by NOTHING ELSE MATTERS

O.K, NOW i am confused

Why do i have to remove the bump out ?

That section of the transom is flat, has the 11* angle and ends up to aprox. 30-31" from the keel to the top of the bump out.

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Feb 02, 2011 4:46 pm

by Chief Brody

I think what Tom is saying is the 1-3/4 you filled in from the inside is only the thickness of the transom in the bump out and the whole transom needs to be 1-3/4.....if you made it even from the inside, the rest of the transom surrounding the bump out may be flat inside, but not the same thickness ( a little less, correct)....so you'd need to make the whole transom an even 1-3/4 by adding more around the bump from the outside, or just shaving the bump and putting one big flat layer of wood to make a uniform thickness transom.....I think..

In other words...what's the thickness of the rest (sides surrounding the bumpout) of the transom? 3/4? 1?

Re: 1981 FORMULA F233 RESTORATION

Posted: Wed Feb 02, 2011 9:01 pm

by NOTHING ELSE MATTERS

To the right and left of the bump out is 1/4" thick.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Feb 03, 2011 4:13 pm

by Chief Brody

NOTHING ELSE MATTERS wrote:To the right and left of the bump out is 1/4" thick.

wow, only 1/4 inch thick for the remaining transom surround? I guess for an I/O its OK...but other than the thick portion of the bump out, that 1/4 inch transom will need to handle a 300HP heavy powerplant......Most transoms hanging a motor are a uniform thickness all the way across......my GW with twin 150's is a solid 2" plus...I would think it would need to be beefed up.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Feb 03, 2011 4:15 pm

by Cracker Larry

That's got to be a mis-type

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Feb 03, 2011 4:34 pm

by NOTHING ELSE MATTERS

Cracker Larry wrote:That's got to be a mis-type

Which one?

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Feb 03, 2011 5:28 pm

by Cracker Larry

Which one?

To the right and left of the bump out is 1/4" thick.

Re: 1981 FORMULA F233 RESTORATION

Posted: Thu Feb 03, 2011 5:35 pm

by tech_support

NOTHING ELSE MATTERS wrote:O.K, i went and measured the angle of the transom and is 11*. Does that mean i can't mount an outboard on a transom with that angle?

Also, the bump out section of the transom is flat and is NOT curved.

Yes, thats close to standard 12

the "bump out" is a cored section. Much better to have a new core span the entire transom (for outboard)

how about some pictures of how the boat is put together?