Poling platform engineering

I just have to resurrect the dead here... Jacques or Joel, any word on plans/how to build a carbon fiber platform? If I recall you mentioned somewhere after the CNC was setup you may be working on it.

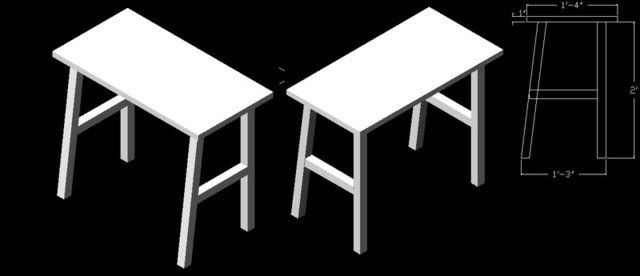

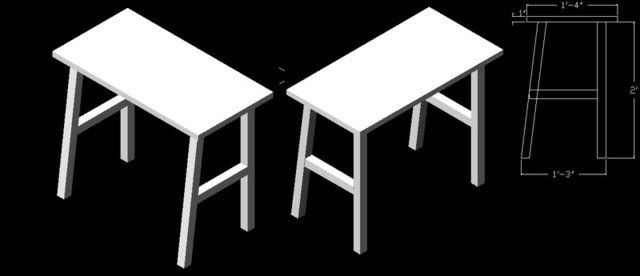

Here is my shot at a plywood/laminate platform. Thinking 1.25 or 1.5" thick ply laminates to make the legs, all corners rounded, wrap with fb biax tape (maybe cf if the couch has enough change!) & then the usual fillets, tape & resin procedure. What do you think?

Thanks,

-Scott

Here is my shot at a plywood/laminate platform. Thinking 1.25 or 1.5" thick ply laminates to make the legs, all corners rounded, wrap with fb biax tape (maybe cf if the couch has enough change!) & then the usual fillets, tape & resin procedure. What do you think?

Thanks,

-Scott

-

FLYonWALL9

- Very Active Poster

- Posts: 1633

- Joined: Fri May 16, 2003 1:00 am

- Location: MOBILE, AL

-

Bayport_Bob

- Very Active Poster

- Posts: 520

- Joined: Wed Dec 31, 1969 7:00 pm

- Location: Tarpon Springs, FL

Personally, I wouldn't use biax tape to wrap the legs with. I would use fiberglass sleeve material. It's expands and contracts and will be much easier to finish than biax tape and all the damn threads sewn in it. The sleeving will also turn translucent if you want the wood to show, biax tape won't.

Email me if you can't find a source for the diameter you're looking for.

Email me if you can't find a source for the diameter you're looking for.

Carbon fiber platform

Have you guys seen this?

Incredible Platforms from carbon fiber!!!!

http://outdoorsbest.zeroforum.com/zerothread?id=733407

Shine, This would look great on your Sheer fs17!!!!

JamesB

Incredible Platforms from carbon fiber!!!!

http://outdoorsbest.zeroforum.com/zerothread?id=733407

Shine, This would look great on your Sheer fs17!!!!

JamesB

- tech_support

- Very Active Poster

- Posts: 12318

- Joined: Wed Dec 31, 1969 7:00 pm

- Location: Vero Beach, FL

- Contact:

- tech_support

- Very Active Poster

- Posts: 12318

- Joined: Wed Dec 31, 1969 7:00 pm

- Location: Vero Beach, FL

- Contact:

Good ideaJimW wrote:Round or octagonal pool noodles would make good CF forms for these tubes.

I may try something different. Im imagining a single 2.5" to 3" diameter CF tube that comes up from under the port side of the rear casting deck about 20 inches off center (tube would be glassed to the transom under the deck). Tube comes straight up to the height of the platform, then takes a 90 degree bend to starboard. The platform would be on the tube.

Its a lot of leverage to put on the tube, but I know I can make it plenty strong with our CF sleeves.

This would leave a very uncluttered transom, with plenty of room to swing my outboard tiller.

Only thing I have not thought of is a good (clean and easy) way to include a step

Joel,

I LIKE IT! It's innovative!

For a step how about a piece of 1/4" ply (or two layers for 1/2") about 3 inches wide and 8 inches long with a single hole cut in the middle to slide onto your support pole. Then fileted on and wrapped with some more CF. CF the hole step piece. The width will have to be at least 3/4" wider on each side than the CF tube?

Pool noodles would work well to form this I think. But how to hold them in the fabrication shape while curing???? A jig with plastic wrapped "holes" to run the tube through in the right positions with nice natural bends??

I LIKE IT! It's innovative!

For a step how about a piece of 1/4" ply (or two layers for 1/2") about 3 inches wide and 8 inches long with a single hole cut in the middle to slide onto your support pole. Then fileted on and wrapped with some more CF. CF the hole step piece. The width will have to be at least 3/4" wider on each side than the CF tube?

Pool noodles would work well to form this I think. But how to hold them in the fabrication shape while curing???? A jig with plastic wrapped "holes" to run the tube through in the right positions with nice natural bends??

Jim Wright

CC, D15, SC16, C19

CC, D15, SC16, C19

Joel,

One thing Bayport_Bob brought to my attention with CF tubes is impact resistance. Bob mentioned that a good knock could fracture the tube, not so with aluminum/stainless. How thick would the CF be on the tubes? Also, ever considered using expandable foam for the molds? 8lb is very dense and would do well. I'm going to use it soon to build handles for fishing rods...

James, the guy that builds the CF Platforms is here in Tampa. He does tons of CF accessories for skiffs; bolt on decks, casting platforms, tiller extensions etc. He is a wealth of information and loves help people with their own projects. If anyone wants, I can provide his contact info off forum.

One thing Bayport_Bob brought to my attention with CF tubes is impact resistance. Bob mentioned that a good knock could fracture the tube, not so with aluminum/stainless. How thick would the CF be on the tubes? Also, ever considered using expandable foam for the molds? 8lb is very dense and would do well. I'm going to use it soon to build handles for fishing rods...

James, the guy that builds the CF Platforms is here in Tampa. He does tons of CF accessories for skiffs; bolt on decks, casting platforms, tiller extensions etc. He is a wealth of information and loves help people with their own projects. If anyone wants, I can provide his contact info off forum.

Who is online

Users browsing this forum: No registered users and 19 guests