Page 1 of 1

Mikem59 FS18 Build

Posted: Fri Apr 19, 2013 8:48 pm

by Mikem59

Well fellow boat builders, and I use that term loosely since I don't qualify as a boat builder just yet, but I finally pushed the checkout button today to order the FS18 kit. I've probably built this boat in my mind several times since I started reading this forum a few years ago. I finally got the courage and the $$, to make the move.

My progress will probably be pretty slow at first and proceed in fits and starts. But, after reading about others just like me, I'm confident I'll be able to build me a fine flats boat. And, based on what I've seen and read on this forum, you guys aren't afraid to chime in and offer invaluable help and suggestions, I'll just need to be sure not to be afraid to ask for help and offer up my pics and help.

While I await the delivery of the goods, I'll start on the strongback. Bought materials for that today.

Hopefully, more to come soon!

Re: Mikem59 FS18 Build

Posted: Fri Apr 19, 2013 8:58 pm

by mjxlange

Good luck on your build. It will make things a lot easier with the kit for sure. Try not to lose momentum and set a dead line. I have taken so many breaks from my build that i'm not sure i will ever finish.

Re: Mikem59 FS18 Build

Posted: Fri Apr 19, 2013 10:20 pm

by Mikem59

Thanks, and yes I do have a deadline, September 1 of this year. I know that without a deadline it will be too easy to let opportune work time slip by. Besides, I'm having to pull my bay boat out of storage to provide me a good workspace.

Re: Mikem59 FS18 Build

Posted: Sat Apr 20, 2013 8:57 am

by Cracker Larry

Welcome Mike

Just take it one step at a time and If you have any questions, ask.

Sept. 1 would be very quick, especially for a first build. You will need to work on it almost full time. Everything seems to take twice as long as you think it will.

Re: Mikem59 FS18 Build

Posted: Sat Apr 20, 2013 4:56 pm

by Pro Wader

It took 17 months for mine to be fishable (I'm still not truly finished)

Re: Mikem59 FS18 Build

Posted: Mon Apr 22, 2013 9:47 pm

by Mikem59

Haven't even started my build and getting good feedback. I figured Sept 1 was ambitious. Maybe I should target having the hull glassed and flipped by that date. Regardless I'll have to take advantage of any available time to work on the build. I'm sure, like most of you all on this forum, you have other jobs to do and you also want to find the time to chase your other passion - fishing.

Got the email today from Mr. Shine confirming my order and a delivery location. Won't be long now.

Re: Mikem59 FS18 Build

Posted: Mon Jun 03, 2013 10:06 pm

by Mikem59

Well, I haven't posted in awhile, but wanted to say I have made some progress. I've built my strongback. At this rate, no doubt a September 1 completion date was very optimistic. Working full time, a good thing, gets in the way of getting long chunks of time to work. I'll be putting in some hours after work during the week to begin making some more progress. And, I must be crazy, but I got a great opportunity to get in on a deer lease, something I've never done in all my years living in Texas. So, work, trips to the deer lease, and build a boat, and fish, Hmmm, I'll be happy to complete by March 1 2014.

I've taken some pics of the materials as delivered along with pics of the strongback, hope to get those uploaded soon.

Re: Mikem59 FS18 Build

Posted: Tue Jun 04, 2013 10:42 pm

by AtTheBrink

Just keep plugging away at it and it will be finished when its finished. I had dreams of splashing mine in 6 months, that came and went 2 months ago...

Re: Mikem59 FS18 Build

Posted: Wed Jun 05, 2013 9:00 am

by wadestep

Mikem59 wrote:And, I must be crazy, but I got a great opportunity to get in on a deer lease

Plan on the boat work being very slow from about Oct through Dec... but you'll be having lots of other fun!

wade

Re: Mikem59 FS18 Build

Posted: Thu Jun 06, 2013 9:38 am

by AtTheBrink

Where is your lease?

Re: Mikem59 FS18 Build

Posted: Sun Jun 09, 2013 9:56 pm

by Mikem59

The lease is just north of Lometa, Tx, which in turn is north of Lampasas. I've been out to the lease 3 times, beautiful out there. Although my passion is fishing, I can see right now, I'm going to enjoy this deer lease.

And, making just a little more progress on the build. I bought the CNC standard sheer,rounded chine kit. Glad I bought the CNC kit for my first build, I'd be a long way from getting ready to glue the stringers and transom pieces.

I got all the pieces separated from the "puzzle" and cleaned up the edges. I do have a question, for the stringer laminations, isn't one side supposed to be slightly shorter to account for the hull shape?

Also, got to trim the middle transom sheet, it for some reason is slightly larger on all sides. I'll get that trimmed this week and I'll get it glued together. I'll probably use the dowel method to make sure the pieces align. I can see right now trying align without them could be difficult.

Re: Mikem59 FS18 Build

Posted: Sun Jun 09, 2013 10:45 pm

by AtTheBrink

The stringers are supposed to be square on the bottom. There isn't much V in this hull and all gaps are filled with the fillet, same thing on the transom.

Dowels are a good idea when glueing up just about every lamination. The epoxy glue you are going to make is slicker than owl snot!

Re: Mikem59 FS18 Build

Posted: Sun Jun 09, 2013 11:58 pm

by Mikem59

Thanks for the input, I feel better about the stringers now. I'm at that stage where I want to be sure before I take that step to start gluing stuff together. And, I'm glad I bought a trial epoxy kit, That gave me a chance to make some glue. Amazing stuff.

Re: Mikem59 FS18 Build

Posted: Mon Jun 10, 2013 7:09 am

by Cannonball

How about some pics... I'd like to see that cnc kit come together. For me schedule was another reason, besides $, to cut the panels out my self. It only took 1 day, but I did have some issues, transom redux and couple gaps here and there. I'm using bayport bobs baseline of 160 hours to get the boat ready for paint, and feel like I'm tracking pretty close. I also am shooting to be done by sept 1. My buddy Paul, aka double up, said it was doable by planning your tasks where you knock out the small items that hold you up for curing time during the week, and put in power sessions on the weekends. That said, listen to these more experienced and trust what they say. I'm also on my first build and they are keeping me lined out.

Good luck, Being from Nederland, sounds like you'll be fishing the other Port A.

Re: Mikem59 FS18 Build

Posted: Mon Jun 10, 2013 1:26 pm

by Mikem59

Yes I need to get some pics uploaded. Not a whole lot for me to show, but I did take lots of pics of the CNC kit as received. Itis nested differently than the standard nesting drawing. I'll make time in the next 2 days to get the pictures uploaded to the builders gallery and then attached to my posts.

And yes, I'll be fishing the other Port A. There's some really great marsh around here to fish as well as Calcasieu.

Re: Mikem59 FS18 Build

Posted: Tue Jun 11, 2013 3:07 pm

by Mikem59

I'm probably getting worked up over nothing since this is a "stitch and glue" but when measuring and marking for center lines on the molds some molds widths are off by as much as a 1/2". Could be the difference between the CNC kit versus the original plans or that this kit was for rounded chine standard sheer. Also the middle transom section is 1/4" wider and 3/8" taller. Tell me I'm worried about nothing and just move on.

Re: Mikem59 FS18 Build

Posted: Tue Jun 11, 2013 3:20 pm

by AtTheBrink

Not sure what to tell ya. Hopefully Jacques or Shine will see this. I would say say post a question in PowerBoats but I kinda got my hand slapped for suggesting cross posting...

Re: Mikem59 FS18 Build

Posted: Tue Jun 11, 2013 3:21 pm

by Cracker Larry

I have never used a CNC kit so not sure about that. With your transom, put the widest piece in the front, narrowest in the rear. The boat is tapered so the transom is widest forward. 1/2 error isn't much for S&G. I'd split the difference and move on, it isn't critical.

Re: Mikem59 FS18 Build

Posted: Tue Jun 11, 2013 3:44 pm

by Mikem59

The widest piece happens to be the one that has a notch in it due to the nesting for the front deck. The plans call for filling that in with a scrap piece and sandwiching this between the other pieces. Also the inner transom piece is notched to receive the transom knees and stringer. But what you say about the width is certainly right, I'll need to double check the measurements on the other pieces and see if I can factor that in. Thanks

Re: Mikem59 FS18 Build

Posted: Tue Jun 11, 2013 4:26 pm

by Mikem59

Going to take a crack at posting a pic. This is of the strong back. Modeled somewhat after Cracker Larry's. if this pic post works. I'll begin posting more.

[img]

http://gallery.bateau2.com/displayimage ... fullsize=1[/img

Re: Mikem59 FS18 Build

Posted: Tue Jun 11, 2013 4:47 pm

by Mikem59

Trying again i think i see what happened. This is of the strong back. Modeled somewhat after Cracker Larry's. if this pic post works. I'll begin posting more.

http://gallery.bateau2.com/displayimage ... fullsize=1

Re: Mikem59 FS18 Build

Posted: Tue Jun 11, 2013 5:27 pm

by pee wee

before you hit "submit", hit preview. If you did it right the photo should show, if not you get to try it again. Right click on the photo you want (at full size), select "copy image url", then past that into your message, highlight what you just pasted in and push the Img button up top. That should do it.

Re: Mikem59 FS18 Build

Posted: Tue Jun 11, 2013 6:46 pm

by Mikem59

Thanks. My biggest problem is trying to do from my iPhone. I don't think it can be done. Thanks again

Re: Mikem59 FS18 Build

Posted: Tue Jun 11, 2013 6:50 pm

by AtTheBrink

On comment on your strongback, and I think Larry will back me up on this, make it shorter. Easy to do now that you don't have a boat on it. 12" is all you need. I started at 18", that was too high so I cut 6" off.

Re: Mikem59 FS18 Build

Posted: Tue Jun 11, 2013 10:24 pm

by Mikem59

I had read about the height and making it too high. I just couldn't convince myself to go lower. I was laying out the molds this evening in preparation for setting up them up on the strongback.

One thing's for sure, I bet I've stared at the plans, read and reread the materials, and stared at the materials for a 1000 hours and done actual work for 1 hour. With all that, plus the few years of lurking I still have lots to learn and lots of questions

Now, here are my next questions, does the transom basically "hang" off the end of the strongback? The reason I say that is that the baseline for the transom is taller than the molds.

And, if that is the case, does the origin need to be offset, say several inches to allow for this? I've gone through a number of pics of some other builds and that appears to be the case. With that said, I think I will offset by 6", meaning my measurements to the face of each mold will be the measurement on the drawing minus 6", for instance, mold "E" on the drawing is spec'ed for 36", now I'll set it at 30".

Hope I don't wear you all out with these questions! I know one thing, I look forward to this build, on one hand, I'm sort of frustrated by the slow progress, but I am enjoying and learning alot.

Re: Mikem59 FS18 Build

Posted: Tue Jun 11, 2013 10:43 pm

by AtTheBrink

Your origen can still be at the end of your strongback, the transom angle will let it clear. Hope that helps, and hope I understood your question.

I remember the excitement when I first started, now I am about to wrap it up and I am really stoked! Feel free to ask all the questions you have, I will try to help in any way I can and lots of other guys are extremely helpful. Good luck on your build. Take your time now and get it right, it will save you tons of headaches and backaches late on.

Re: Mikem59 FS18 Build

Posted: Tue Jun 11, 2013 11:02 pm

by Mikem59

Yes, you understood my question, and yes, that makes sense. I was toying around with that on the strongback this evening, and wasn't sure if it would clear. That's good since I had already struck my lines on the strongback for the mold locations, not that it would have been difficult to change.

More pictures coming, trying to synch my iphone photos to my pc via the "Cloud" to simplify the process of uploading and posting. Right now, that ain't work'in so good. Maybe I need to go out onto a "Cloud" forum to figure that one out.

Re: Mikem59 FS18 Build

Posted: Tue Jun 11, 2013 11:19 pm

by Mikem59

Re: Mikem59 FS18 Build

Posted: Wed Jun 12, 2013 8:22 am

by AtTheBrink

I've never seen a CNC kit before, pretty cool stuff. That bow mold they sent you is going to really help you with the round chine. I really wish I had cut one for my build. This boat isn't immune to the Droopy Bow but it isnt as bad as some.

Re: Mikem59 FS18 Build

Posted: Wed Jun 12, 2013 12:50 pm

by Uncle D

Mikem59 wrote:The lease is just north of Lometa, Tx, which in turn is north of Lampasas. I've been out to the lease 3 times, beautiful out there. Although my passion is fishing, I can see right now, I'm going to enjoy this deer lease.

As a kid we hunted at my great uncle's ranch out of Lometa. The Hood Ranch. And that is beautiful country.

I pass by Nederland all the time.

Don

Re: Mikem59 FS18 Build

Posted: Wed Jun 12, 2013 10:24 pm

by Mikem59

Don, we're on a lease called the Bear Creek Ranch. Looking forward to squeezing in time to go out there. The good news, lots of dove, hogs, turkey, and deer. My hunting buddies are pretty fired up as the lease they were last on did not have dove nor much in the way of hogs or turkey.

Now onto an update. Achieved a milestone this evening, got one set of stringers glued together. And, as expected the things that went well were due to all the tips and tricks posted by others. In particular, using 3/8" dowels to keep everything aligned. Without those I would have fought keeping things aligned while trying to clamp everything together. I bought some clamps at Lowes, based on tonight's experience, I need more!

As for a key learning and something I'll probably struggle with for awhile is batch size. I wetted out each of the pieces first using a total batch volume of 150 ml. That was pretty darn close to what was needed. As for the epoxy glue batch I should have stuck with the same volume. Instead I went with 300 ml. I thought the wood flour would require more volume. After completing, I probably had 75 ml leftover and didn't have anything else prepped to glue.

And the cure times I found in the help somewhere are probably pretty good. It called for a cure time of 49 min at 85 deg for the slow hardner. This small batch kicked in about 35 min. So that's probably about right. With that cure time, and working by myself, I would not have had enough time to glue anything else anyway.

I'll post some pics shortly.

Re: Mikem59 FS18 Build

Posted: Wed Jun 12, 2013 10:39 pm

by Mikem59

Here's that bow mold from the CNC kit. As you can see, I had to scab it together as it had broken during shipment.

Clamps, and now I know, not really enough of'em:

Wetted out stringer sections:

Aligned, glued, and clamped together, as you can see, I celebrated my accomplishment:

Re: Mikem59 FS18 Build

Posted: Wed Jun 12, 2013 10:42 pm

by AtTheBrink

When you mix up batches of epoxy, epoxy glue, or fairing compound you can stretch your working time a bit by getting it out of your mixing pot and spreading it out on something like a piece of cardboard covered in packing tape. It slows down the cure by not allowing the heat to build up. When are you planning to start stitching her together?

Lookin' great so far!

Re: Mikem59 FS18 Build

Posted: Thu Jun 13, 2013 7:37 am

by Mikem59

I recall seeing that tip to use cardboard or a paint pan. And I'll give that a try when I decide to tackle more pieces with one batch or in one session. I'm glad I just did the one piece. As for a date for starting the stitching I'm thinking I can get to that stage by late this month. Have a couple of trips to take that are going to slow me down a little

Re: Mikem59 FS18 Build

Posted: Thu Jun 13, 2013 2:33 pm

by Uncle D

you can never have enough clamps...

Re: Mikem59 FS18 Build

Posted: Thu Jun 13, 2013 5:43 pm

by Mikem59

Ha, I've seen that pic and you are right.

I've seen a few of the guys use PVC as clamps for the rub rail, unless someone feels that's more trouble than its worth I'm going that route. Regardless, I still need more clamps.

The first set of stringers went good. They are no doubt glued together. Got some cleanup on the top and bottom edges for all the epoxy glue that squeezed out.

Second set just completed gluing.

Now off to Pennsylvania to visit family for the Fathers Day weekend. I'll have some completed stringers waiting for me when I return next week.

And Happy Fathers Day to all you dads out there. Hope you all get out in your boats and get on some fish!

Re: Mikem59 FS18 Build

Posted: Thu Jun 20, 2013 8:40 pm

by Mikem59

Stringers glued, cured, and I've begun cleaning them up. And I had purchased a Stanley sure form plane and can see why it was recommended. Thanks to Cracker Larry as I believe it was on his build thread I picked that tip up.

As for tonight, siphoning gas out of my current boat. I guess after nearly four years the tank managed to accumulate some water and ruined my last attempt to head out fishing. Fuel rail and injectors cleared and cleaned. Big thanks goes out to the boat Ramp in Port Neches for the quick turnaround.

Why I didn't have a fuel water filter separator on this boat I don't know, but its installed now as well.

Hope to get in some boat work over the weekend. I'm ready to glue the transom as I've got those pieces cleaned up and have installed some 3/8" alignment holes. Pressing forward !

Re: Mikem59 FS18 Build

Posted: Thu Jun 20, 2013 9:12 pm

by AtTheBrink

PVC clamps- I used them on my boat and they work good. I used 3" pipe and cut them 1 1/2" wide. I used a 10" miter saw to cut them. Be careful and go slow, that pvc can get ugly quick!

Re: Mikem59 FS18 Build

Posted: Mon Jul 08, 2013 9:37 pm

by Mikem59

Not a whole lot of progress on my build of late. I've only managed to do some cleanup of the glued stringers and the transom. That leads me to a question regarding my transom.

I plan on mounting an Atlas Micro Jack Plate along with a 20 hp Suzuki 4 stroke. I'd like to put on the short, 15" shaft model. I don't have the exact measurements, but assuming it is 15" shaft, do I cut down the transom to match? Or, just stay with the plans and match up with a 20"?

And, I've noticed on some builds that the transom is thickened/reinforced. Is that necessary given my jack plate and motor plans?

Re: Mikem59 FS18 Build

Posted: Tue Jul 09, 2013 12:30 am

by Shamrock Kid

Mikem59 wrote: I've noticed on some builds that the transom is thickened/reinforced. Is that necessary given my jack plate and motor plans?

The plan calls for the transom to be three layers laminated together. I think as long as you follow the plans you will be fine. Im not and expert and am on my very first build myself. But I'm sure the more experienced builders will agree to follow the plans and you cant go wrong.

Re: Mikem59 FS18 Build

Posted: Tue Jul 09, 2013 7:02 am

by Cracker Larry

The transom is plenty strong enough as designed. I would leave it at 20" and use the jack plate to adjust the engine height.

Re: Mikem59 FS18 Build

Posted: Tue Jul 09, 2013 10:27 pm

by Mikem59

Thanks and yeah I agree I will leave the transom at 20". I looked at a boat today with a jack plate and a 40 hp and see that it should be a relatively simple and the transom should be plenty strong as mentioned. As much as I would like a short shaft motor, I'm not really sacrificing much in the way of added weight.

Sure wish I had started this build months ago so I'd have another boat to fall back on. My Blue Wave is out of commission, due to a little incident with some rocks resulting in a bent prop shaft, and minor hull damage. Glad I still have boat insurance.

Re: Mikem59 FS18 Build

Posted: Wed Jul 10, 2013 11:07 pm

by Mikem59

Got an opportunity to get in some work tonight and I must say it felt good to make this step. Got the frames and molds loosely fitted on the strongback. Had to do some minor trimming of the slots to get the stringers and molds "married" up, but all in all no issues there. The only question I have is with the transom knees. When I dry fitted/clamped the knees to the stringers, they don't rest flush on the strongback, they are 1" below the strongback. Obviously, the stringers can be raised up so that they will be flush, but they won't be resting on the molds - is that ok? I suspect it is as I believe the stringers should be flush with the top frames and molds as they sit on the strongback. But before I square everything up and secure everything to begin the planking, I want to be sure that is correct.

I'll post pics when I get to my pc.

Re: Mikem59 FS18 Build

Posted: Thu Jul 11, 2013 8:45 am

by Cannonball

I built the FS18 with the deck upside down on the strong back and when I clamped on the knees, the tops of the knees rested on top of the deck and lined up without any issues. This would be best for Shine to answer since it's a CNC package.

Re: Mikem59 FS18 Build

Posted: Thu Jul 11, 2013 10:06 pm

by Mikem59

Here are some photos of my latest progress, loose fitting of frames/molds on the strongback. I've stayed with my original height of the strongback. Hopefully, I won't regret that decision. Once I flip the hull, I'll look at lowering to accommodate the interior work.

Here's a view from the transom end. I suspect you experienced builders will see some issues with my strongback.

Yep, the support legs need to be on the inside to allow for the transom to sit properly to fir up the stringers and knees; and, with my strongback narrower than the builder notes, the knees will not rest on the strongback. Both will be easy fixes.

And, as you can see, the knees are sitting 1" below the strongback. It appears that if I lift the stingers to have the knees rest flush, the stringers will be flush with the frames/molds as well.

Once I finish up with a mini-church retreat Saturday afternoon, I plan on getting in some time over the rest of the weekend. Hope to center/square up everything to secure and prep for the hull planking.

I know one thing, I'm enjoying the heck out of this.

Re: Mikem59 FS18 Build

Posted: Thu Jul 11, 2013 11:47 pm

by AtTheBrink

It is fun ain't it!?!

I can see in you pictures that the notches are deeper than they need to be. Just shim them up to flush with the frames and you will be good to go. Everything looks good. Get it all square, level, flush and plumb and there aint much that can go wrong!

Wish I had had a bow mold...

Re: Mikem59 FS18 Build

Posted: Fri Jul 12, 2013 4:41 pm

by Mikem59

Thanks Mike for the confirmation that all I need to do is shim up to get the stringers flush with the frames.

As for the bow mold, I would suspect that it will be very helpful. Looking forward to getting everything squared up and moving on to the next step.

Re: Mikem59 FS18 Build

Posted: Wed Jul 17, 2013 10:58 am

by Mikem59

Guys, I have what may be a dumb question, when joining the hull panels, do you do one side at a time? If not what's the trick to doing both sides in one session? Ive gone through some of the other builds and its not clear to me how this is done. Thanks Mike

Will post some pics soon but have finally got everything square, plumb, and secured on the strongback and ready for hull planking.

Re: Mikem59 FS18 Build

Posted: Wed Jul 17, 2013 11:13 am

by Cracker Larry

Lay the bottom panels on the jig first with them loosely stitched down the middle. Then loosely stitch one side panel onto the bottom, then the other one. With all panels hanging loose, start tightening the stitches a little at a time, working evenly around the boat.

Re: Mikem59 FS18 Build

Posted: Wed Jul 17, 2013 12:42 pm

by Mikem59

CL. Thanks for your reply. And, I realized after I posted my question I had poorly phrased it. My question revolves around joining, gluing, and glassing together the individual hull panels. Maybe i should say splice together the hull panels. I have not yet joined/spliced the individual hull bottom or side panels as yet. Hope that is more clear. Thanks

Re: Mikem59 FS18 Build

Posted: Wed Jul 17, 2013 12:49 pm

by Cracker Larry

Sorry, I misunderstood the question

I splice one side at a time. I've tried doing both and it always comes out sloppy on one side.

Re: Mikem59 FS18 Build

Posted: Wed Jul 17, 2013 12:56 pm

by AtTheBrink

Are you talking about splicing the pieces together to make the panels? If so, you do one side at a time. Make sure you have a flat clean surface to work on and back up the joint with something that epoxy wont stick too. I used plastic packing tape, that helped contain any seap thru and minimized sanding on the other side when I flipped it, but you can just put a piece of sheet plastic under the joint. Prep the joint with neat epoxy, fill the joint with epoxy/woodflour glue(you want the glue fairly stiff so it doesn't run out or sag leaving an air pocket) and then tape it. Let it cure, flip it and do the other side.

Just a tip, sand or plane down the ends you are joining enough to make a flat finished joint. It will save you a lot of fairing. You can just do the outside of the panel.

Re: Mikem59 FS18 Build

Posted: Wed Jul 17, 2013 1:17 pm

by Mikem59

CL and Mike, once again thanks for the replies and yes you have both answered my question. And will just plain plastic be sufficient for backing to prevent the epoxy from sticking?

Re: Mikem59 FS18 Build

Posted: Wed Jul 17, 2013 1:45 pm

by Cracker Larry

Yes, about any kind of plastic. I buy a big roll of cheap drop cloth plastic and cut off pieces as I need them.

Re: Mikem59 FS18 Build

Posted: Wed Jul 17, 2013 9:42 pm

by Mikem59

Yeah, I've got plenty of plastic, I bought a couple of the drop cloth plastic rolls. And, as you can see, I've already covered the floor of the work area.

In this pic, you can see the floor covered up beneath and to the side of the strongback. And, I was so excited to have the molds/frames squared up, plumb, and secure that I just had to lay the hull bottom panels to get a rough idea how they will fit.

While I'm finally at my computer instead of an iphone or ipad, I'll post a few pics. Not terribly exciting for most of you, but I'm real pleased with my progress,and completing each step is such a confidence builder. I've seen it said a lot on the other builder posts, but, yes, "just follow the plans" and things do come together. But yes, questions do come up, but the help out here is just phenomenal.

This threw me off for awhile, the transom not looking as though it was flush with the top of the knees and stringers. But photos on CL's posts seemed to confirm that was how it is supposed to be. And, yes, once I put the panels on top, it was like, of course, the panels sit flush on the back of the transom due to the angle, duh. Once again, just follow the plans and don't overthink it.

But here is a photo of an issue I'm not sure about. The stringers, remember from the CNC kit, when glued up are flush on both edges for most of the length, but there is a section whereby they are only flush on one edge. If this is going to be a problem down the road, let me know, otherwise, I may do some minor trimming just to ensure the stringers remain level for when I begin the hull planking. Also, you can see the dowel plug used for aligning and keeping them aligned during gluing. Worked like a charm for the stringers as well as the transom.

Lastly, here's another photo looking straight on the completed "jig". You may recall the bow mold had broken during shipment. I had finally epoxy glued it back together. But once I completed everything, had some concerns about the strength of that bond once I begin planking. So, I braced it as well.

Re: Mikem59 FS18 Build

Posted: Thu Jul 18, 2013 6:11 am

by Cannonball

Coming along nicely. The uneven stringer lamination shouldn't be a problem as long as the stringers are straight and will allow the hull panels to rest on them without creating any hook or rocker. Later the topsides will get cleats and the underside will get an epoxy fillet that will make that go away. One piece of advicc, Take Your Time Stiching! I wish I would have spent a little more time making sure everything was straight and true befor gluing up. All in all it only takes a half a day to really get everything hung drill holes and stitched. Take an extra couple hours to pull some string lines over the bottom to check for hook (fs18 seems to be prone to a slight hook I've seen everybody have to push out), do that and you'll save some time later.

Re: Mikem59 FS18 Build

Posted: Thu Jul 18, 2013 8:46 am

by Mikem59

Cannonball, thanks for the input and advice. One thing I did make sure of was that everything was square, plumb, and level. Like you say, I figured that what is now the top edge of the stringer will become the bottom and will then be glued to the hull. And I recall reading that the stringers shouldn't be in direct contact with the bottom, the epoxy resin fillet provides the bond to the hull. Given that understanding and your confirmation I feel good about the stringers. As for the advice on the stitching, thanks for the heads up, getting the hull "fair" is a big deal from what I've gathered. I'll make special note of this advice.

Thanks

Re: Mikem59 FS18 Build

Posted: Thu Jul 18, 2013 11:00 am

by AtTheBrink

What's up with your bow bottom panel? It looks like there is some trimming that needs to be done. That is an exciting part of building a boat! Seeing the hull come together is always cool!

Re: Mikem59 FS18 Build

Posted: Thu Jul 18, 2013 11:11 am

by Cannonball

You bet. Just a note: The stringers should be in contact while your at this stage to keep the bottom level, and your correct they will sit up off of it a bit when you fillet them in after the hull flip. Hoping to flip this weekend myself.

Re: Mikem59 FS18 Build

Posted: Thu Jul 18, 2013 11:17 am

by jacquesmm

1. Transom: why does it not line up at the bottom? It should. What reference did you use to set the height of the transom?

With the kit, you don't have to measure anything, simply put the transom on the jig lined up with the stringers and that's it.

BTW, you line up the outside edge with the stringers, not the inside. After planking, there will be gap that you fill with putty. Maybe that is what we see in your picture, it may be correct.

2. Stringers: Why does layer one not line up at the bottom? Did ti shift while you were gluing? The two layers are perfectly identical, they should match.

Do the port and starboard stringers match? How much is the difference?

It looks very small and as you write, it should be easy to shave that 1/4" off but I wonder why there is a difference.

The stringers must be perfectly straight for the stern half of the hull. Make them straight by shaving that little bit off or if there is a gap, no problem, it is small and will be filled with putty.

All together, I see no real problem but I wonder about the two points above.

The kit is cut from the CAD file. In the CAD file, I do not draw 4 layers of stringers. I draw one and copy it. It is mathematically 100% identical, same control points. Those points are used by the machine to cut, there should not be any difference unless a piece moved a little bit during the cutting.

Re: Mikem59 FS18 Build

Posted: Thu Jul 18, 2013 5:30 pm

by Mikem59

Wow, once again, a lot of support out there. I'm responding not only to address the questions but, apparently for my own good.

Mike - nothing wrong with the bottom panel, at least I hope not. They were just layed up on top of the molds, but I didn't lay the bow panels flush with the middle panels. I've certainly not modified them in any way from the CNC kit. So, I expect they are perfectly fine.

Cannonball - no doubt, yes, those stringers will be in contact during the hull planking.

Jacques - I'm certainly hopeful there aren't any issues with my transom. I lined it up as you state, with the knees and stringers lining up in the cut out in the transom. I did have to make a slight adjustment post picture as the one side didn't get seated in quite right. That has since been corrected. And, once the panels are laid down, they do rest flush with the back edge of the transom. After doing that, it made sense to me. Again, hope that is correct. It was a simple geometry lesson for me. I don't recall the angle of the transom, but due to its angle the back edge "kicks up" just a little such that it makes up for the apparent difference at the part that is mounted to the transom knees and stringers. And, the following picture from Cracker Larry's FS18 build helped me decide I was alright.

As for the stringers, I would most certainly agree, one would think the CNC cut stringers should be identical, but they weren't. At first, I though perhaps one was supposed to be taller than the other due to the hull shape, but once I put them in the frames/molds, the edge you might expect to be longer/shorter to accomodate for the slight difference in hull shape didn't make sense regardless of which set of stringers went where. Also, prior to gluing them, I lined them up and no matter how I did it, one edge was slightly taller than the other. So, when I glued them, I used 3/8" dowels to align them and keep them from "slipping" while gluing. And, knowing the bottom of the stringers, upon flipping, would be glued/filleted to the bottom, I made sure that was the portion that stood taller so I could trim if needed.

I realize that doesn't answer the question as to why they aren't exactly the same size along the entire length, but I don't see it as a showstopper. I will make the minor adjustments to ensure the panels lay flush with the stringers, frames, and molds as well as remain level. And, the height difference is maybe a 1/4". Very fixable with time, and, well patience.

I'm hoping to get the bottom panels joined/spliced this evening. Out of town over the weekend, so I won't finish the side panels till next week. Factor in the rub rail construction, I don't see flipping for at least a few more weeks for me.

Thanks again to you all!

Re: Mikem59 FS18 Build

Posted: Mon Aug 05, 2013 7:36 am

by Mikem59

Finally completed joining the bottom hull panels, but I'm a bit disappointed

in my effort and need some insight on whether I need to make some fixes now, not at all, or wait till I get'er stitched and glued and ready for glass. Below are a couple of photos of the joints.

In this pic, there are some gaps where the resin didn't fill all the way in and the fiber glass was not quite as wide as the section I had planed out for the joint.

Similar in this pic, but more pronounced.

My mistakes were making the planed out portion of the joints to wide for the fiberglass; and, upon completing the glassing, I did not apply even pressure over the joints while curing.

I don't want to get ahead of myself here and regret making a bad decision this early in the build. Looking for the right step to take here.

Thanks.

Re: Mikem59 FS18 Build

Posted: Mon Aug 05, 2013 9:47 am

by AtTheBrink

I am not sure what you are talking about. What gaps? It looks pretty good to me. Remember it is easier to fill and fair a low spot than sand and fair in a high spot. The only thing I see is you used a bit too much epoxy.

Do you have pictures of the back side of your joints?

Re: Mikem59 FS18 Build

Posted: Mon Aug 05, 2013 12:48 pm

by Mikem59

Mike, thanks for the comments. The joints have some gaps near the edges that are hard to see. But, as you say, better to fill and cair than to have to deal with a high spot. And, yes too much epoxy. I guess I'll chalk that up to beginner mistake. I think I'll do some filling with a fairing mix now rather than after I stitch and glue the panels.

Thanks!

Re: Mikem59 FS18 Build

Posted: Mon Aug 05, 2013 1:15 pm

by Cannonball

Take a look at Cracker's FS18 when he's glassing in the middle of his thread somewhere, I think page 40-50 somewhere there's a Cracker tutorial. Use 1 oz of epoxy per 1' of 12 oz tape. I've used this as a general rule after using too much on my panel joining and it has served me well since.

Re: Mikem59 FS18 Build

Posted: Mon Aug 05, 2013 2:42 pm

by Mikem59

Cannonball - yes I remember seeing a go by for resin to glass somewhere. And I tried to use that basis. I just need more practice. Thanks!

Re: Mikem59 FS18 Build

Posted: Mon Aug 05, 2013 6:46 pm

by AtTheBrink

No worries, my first joints looked just like that. You learn as you go. You will be an expert in no time.

Re: Mikem59 FS18 Build

Posted: Tue Aug 06, 2013 9:12 am

by tech_support

its fine. The glass is wet out, thats what matters. Dont bother with the plastic peel ply unless you can put enough weight on it to make it FLAT.

When I mix epoxy I plan on 1 oz. per foot of 6 in tape, but it goes almost double that if you doing two layers wet on wet.

Re: Mikem59 FS18 Build

Posted: Tue Aug 06, 2013 9:35 am

by gk108

Yep, what Joel said. On these splice joints where you have planed the plywood, it's just as easy to leave out the plastic and sand down the binder threads before applying filler to fair the joint.

On areas where you use the plastic, dry squeegee or dry roller on top of the plastic to force excess resin out of the tape. Even if you end up with little resin pools away from the tape and joint, that's still easier to clean up than pools on the tape itself.

Re: Mikem59 FS18 Build

Posted: Tue Aug 06, 2013 5:18 pm

by Mikem59

Based on what I'm reading, seems that I could just move ahead to stitch the panels then do the filling and fairing when that step comes into play. My main thing was ensuring I don't move forward with a problem that can't be fixed later. Thanks for the input!

Re: Mikem59 FS18 Build

Posted: Tue Aug 06, 2013 5:51 pm

by gk108

do the filling and fairing when that step comes into play

That's about the way it is. There may be a few places where you want to fair first because of ease of access, but not many. You definitely don't want any lightweight filler between the splice tape and the chine tape, etc.

Re: Mikem59 FS18 Build

Posted: Tue Aug 06, 2013 5:54 pm

by Cracker Larry

Yep, what GK said. Just carry on

Re: Mikem59 FS18 Build

Posted: Thu Sep 05, 2013 9:24 pm

by Mikem59

Wish I could say that my long absence from the board meant that I've been working feverishly on my build. Work, a family vacation, other committments have kept me from getting alot done. But, I have stitched the bottom hull panels, made the round chine cuts, and have the panels on the jig. Overall, I'm pretty pleased with what I see.

I'm pretty sure I've read in the "How To's" and/or on some of the other posts that there should be a gap, say 1/4" between the panels. Right now, I've got the stitches as tight as they'll go and have the panels pretty much butted up against each other. The fit is pretty good, the panels do raise up off the C & D frames a little. I think that going back and restitching a little more loosely will help that as well as be the correct way to do this anyway. Am I on track with that thought process?

Re: Mikem59 FS18 Build

Posted: Thu Sep 05, 2013 9:45 pm

by Fishwater

You seem to have it down. Take your time at this point...believe me. Make sure everything is as you want it before you start "tacking it" and certainly before you start glassing. I think the key is to have everything stitched loosely and then slowly make adjustments. The PVC trick works too. Take some small diameter pvc, cut it into short lengths (you won't need them more than 3") and place it on the underside where you're going to stitch. Feed the ziptie through one hole, around the pvc, and then back through the other hole and cinch the ziptie. Not sure if that makes sense. One of the first guys to build the FS18 figured it out. It's on his thread...maybe Bayport Bob?

Re: Mikem59 FS18 Build

Posted: Thu Sep 05, 2013 10:51 pm

by Mikem59

Thanks for the input. I have the PVC technique posts already bookmarked for quick reference. When you mention tacking, how do you recommend doing that?

Re: Mikem59 FS18 Build

Posted: Fri Sep 06, 2013 8:01 am

by Cannonball

If I could go back and do it again I would use west systems six 10 for tacking. Little pricey, but you can get it for $18 a tube on amazon and it will save you loads of time with clean up. I went way heavy on the tacking and regretted it.

Re: Mikem59 FS18 Build

Posted: Fri Sep 06, 2013 9:10 am

by AtTheBrink

You are doing great! Loosening (is that a word?) the stitches along the keel will let the panels relax and you should be good to go. You want a small gap there. The PVC trick will really help you with the round chines. Take your time! Lastly, Cannonball is right on about using something like West 610, it is the caulk tube that makes it easier and cleaner with less wwaste. You can get empty ones and use your own mix and save some $$$. Putting packing tape on the back side of all the joints will save epoxy, time, and headaches!

Re: Mikem59 FS18 Build

Posted: Mon Sep 09, 2013 7:02 pm

by Mikem59

Was out of pocket for a few days, just now saw the follow up replies. Once again thanks for the help. As usual I have some follow up questions. For tacking with the West Systems material, would I use that to tack the panels to the frames? And, does it release easily? And yes I used the packing tape.

Re: Mikem59 FS18 Build

Posted: Mon Sep 09, 2013 7:46 pm

by Cracker Larry

The fit is pretty good, the panels do raise up off the C & D frames a little.

Just put some weight on them to hold them down. This is the one I built, stitched and tacked, with weights holding the hull down on the frames.

For tacking with the West Systems material, would I use that to tack the panels to the frames?

At this stage of your build you don't want to attach the frames to the panels at all. Just let the panels float on the frames while you tack the hull panels together.

Marinepoxy and wood flour works fine for me

Re: Mikem59 FS18 Build

Posted: Mon Sep 09, 2013 9:28 pm

by Mikem59

Gotcha, I let myself get confused on "Tacking". So, I think by loosening my stitches, that should "relax" the panels, suspect I'll still need to weight them to get them to rest on the panels. As for the tacking, is the the West System 610 an alternative to epoxy and wood flour?

Wanting to get straight on all this as I'm planning on getting all the panels stitched and glued over the next two weeks.

Thanks All!

Re: Mikem59 FS18 Build

Posted: Mon Sep 09, 2013 10:21 pm

by Shamrock Kid

Mikem59 wrote:As for the tacking, is the the West System 610 an alternative to epoxy and wood flour?

It is a thickened epoxy that can be used for structural adhesion. So yes you can use it in place of epoxy/wood flour. It would get mighty expensive to use it verses epoxy / wood flour for the entire boat. I think for tacking it would be fine. I like the epoxy would flour myself I ordered the kit and had plenty of wood flour on hand. Mixes easy, and spreads easy as well. But I didn't do the modified chine so your going to do allot more tacking then I did. Might be better to use the Six10 that was suggested, Idk.

Re: Mikem59 FS18 Build

Posted: Mon Sep 23, 2013 9:43 pm

by Mikem59

Well, over the past few weeks, I've made some progress. Finished stitching the boat together and tack/glued everything. Here are some pics along and with some comments.

The beginning process of zip tying for the rounded chine

I didn't see the whole process explained, but figured the easiest way was to do the bottom panels first before attaching the side hull panels. The bottom hull panels has a nice gap until I got close to bow end. Here, they butted up against each other. I hope I don't regret breaking it down and sanding or planing to get a consistent gap.

Attaching the side hull panels is a bit challenging by yourself, but managed with the help of some horses, saw horses that is. And, decided to loosely stitch the rounded chine cuts at the end to keep those strips from going wild on me.

Re: Mikem59 FS18 Build

Posted: Mon Sep 23, 2013 9:56 pm

by Mikem59

Here she is, stitched and glued.

I'm a little concerned with the fillets here to get the 1/2" radius. Can I build these up with more epoxy/wood flour glue? Or, are they workable as is?

Lastly, here's the bow all "gorilla snotted" together. The mix was just a tad to thin when I applied. I may have some difficulty getting those zip ties out and I guess I'll be doing some sanding. From what I've gathered, I'll be doing alot of that no matter what.

And, I may have gotten carried away with the zip ties for the rounded chine option. My spacing was pretty tight and made for some difficulty tacking between zip ties.

Overall, I'm super excited to be at this point. Look forward to cutting the zip ties and filling in the remaining gaps. Again, my biggest concern is making sure I get that 1/2" radius.

Re: Mikem59 FS18 Build

Posted: Tue Sep 24, 2013 9:58 am

by tech_support

from here is looks very good.

Dont worry about the zip ties, they grind right off.

I would build up the chine putty a little more, then sand/grind it flush from top and bottom, then round it over.

You can put some "blobs" of putty on the underside in key places to keep anything from popping loose when you grind off the stitches from the outside

Re: Mikem59 FS18 Build

Posted: Tue Sep 24, 2013 5:33 pm

by Mikem59

Thanks for the advice. I figured I'd would have to build up the chines. And, I believe I will tack from the underside in some key spots. I'd hate to see everything start popping loose. I'm particularly concerned with the rounded chine area staying together. Thanks again!

Re: Mikem59 FS18 Build

Posted: Tue Sep 24, 2013 7:29 pm

by Cracker Larry

That epoxy is a lot stronger than you think it is. It won't pop loose, not as much as you have on there. Looking good

Re: Mikem59 FS18 Build

Posted: Tue Sep 24, 2013 10:38 pm

by Mikem59

the first time builder in me is showing through. No doubt after seeing resin set up in a mixing cup demonstrates how strong it is. And, yes thinking back to gluing the transom and stringers shows the bonding strength to wood as well. At least I won't be too nervous when removing the zip ties.

Re: Mikem59 FS18 Build

Posted: Tue Sep 24, 2013 11:54 pm

by Cracker Larry

The glue is 100 times stronger than the plastic zip ties, cut them

Re: Mikem59 FS18 Build

Posted: Wed Sep 25, 2013 12:50 pm

by Mikem59

you got it I'm going to cut'em. Thanks

Re: Mikem59 FS18 Build

Posted: Mon Sep 30, 2013 9:51 pm

by Mikem59

Cut those zip ties last Wednesday, no problems. Looks good without'em. And, the boat didn't explode

.

Looking forward to filling in the gaps in the glue and building up the chine to make sure I get that 1/2" radius. Unfortunately, work/travel will keep me away for a few days, and then, off to the deer lease this weekend, not a bad problem to have.

Here are a few photos after the zip tie cutting.

She may not have exploded, but there are alot of pieces of pvc on the floor. I used 237 zip ties and 172 pvc pieces.

Re: Mikem59 FS18 Build

Posted: Tue Oct 08, 2013 6:14 pm

by Shamrock Kid

Is it still holding up Mike?

J/K of course it is that epoxy is some strong stuff. Any updates?

Re: Mikem59 FS18 Build

Posted: Fri Oct 11, 2013 6:12 pm

by Mikem59

yessiree. Holding together just fine. That resin is amazing stuff.

I've managed to fill in all the zip tie holes, glue the gaps where I had the zip ties, lay down a coat of resin and glue over the seams, and plane the excess glue off. I'm ready to sand to get a more fair surface and lay down the glass on the seams. I'm planning on completing that over the next week.

I'm getting anxious as I know I'm getting close to the point when I'll be able to flip the hull. Well maybe, in reading all of the various builds, glassing the hull and getting it fair will be a timely and crucial phase of the build. And, although this is my first build, I really want a great looking, smooth, and fair hull. I'd like to think I can get it to look as good as a production boat hull. And from what I've seen on this forum, I know it can be done.

Re: Mikem59 FS18 Build

Posted: Mon Oct 14, 2013 1:30 pm

by Cannonball

If your going to lay down the glass tape, go ahead and plan on doing it all wet on wet. Pay attention to the lamination schedule, there are a couple different ways to do it. I would get a table ready with everything pre measured the night before and recruit a couple hands. Before I started I didn't fully understand the big push to do everything wet on wet, but it will save you a lot of time. Just think with a little preplanning 6 hours one day. Or, 4 hours taping one day, 2 hours sanding/cleaning the next day, and then 4 hours cloth lay up on the 3rd day. That is what the wet on wet decision is all about.

Re: Mikem59 FS18 Build

Posted: Wed Oct 16, 2013 11:32 pm

by Mikem59

Cannonball, thanks for the info. With what little experience I've had so far and certainly from your advice and what I've read throughout the forum, wet on wet will be the way to go. And, yes, I'll be recruiting some help as well. I've seen that you and others get ready with premeasured amounts of resin and hardener to keep things going when you are ready for another batch. And, with the weather finally beginning to cool down, I think I'll still use the slow hardener to give me some more time to work wet on wet.

As far as my progress, I've completed the gluing step. And, I believe I may have overdone the glue. I used the heck out of the Stanley Sureform Planer, as Cracker Larry stated, great tool. Then, I've sanded for three hours. Seemed like an awful lot of sanding for what I think Cracker Larry called light sanding before the seam glassing step.

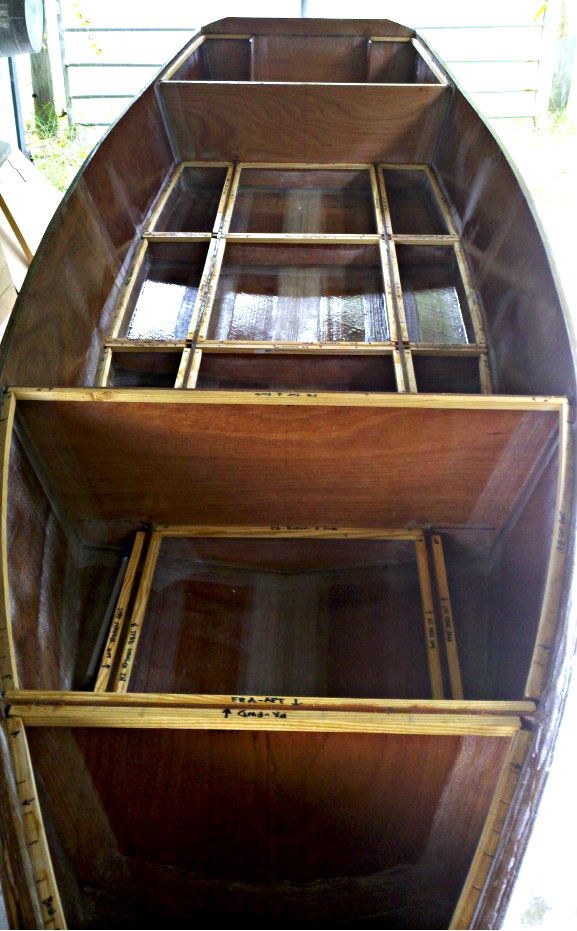

Here's the post gluing outcome, which was achieved by the tabbing between the zip ties, pulling the ties, patching up the zip tie areas, then going over with a coat of resin then a epoxy glue coat (wet on wet).

And, here's the appearance after the sanding.

I know it's difficult to see the "quality" of the surface from the sanding. I hoping that at this phase, having a "fair" and extremely smooth surface isn't necessary. I'm probably a bit paranoid, but I do think I can move onto the seam taping/glassing step. But, I'm concerned that instead of the taping/glassing of the seams taking care of any slight imperfections in the surface, it may magnify them. Any thoughts?

Re: Mikem59 FS18 Build

Posted: Thu Oct 17, 2013 9:10 am

by Shamrock Kid

Looks good from where I'm sitting, but I do know anything you take care of now will make it easier later. If there are spot of raised glue you definitely want to sand down smooth. If not the cloth will not lay flat, and will trap air under the lamination. No good at all, if you have small voids on the seams were the glue has settled you might want to fill them. The cloth will not droop down in those areas but you most likely will trap air bubbles there too. Making a weak lamination. When CL says light sanding don't forget he has built a few and his work is allot better then most. I tend to work very messy and spend allot of time sanding because of it.

But getting it fair now will pay off after you glass it. Fairing sucks

Better to minimize it as much as possible imo. Im no expert though, I'm sure others will chime in. But from what I see your doing a great job so far. Keep it up and keeps the pics coming as it motivates me to press on.

Re: Mikem59 FS18 Build

Posted: Thu Oct 17, 2013 5:56 pm

by Mikem59

John, thanks for the feeback and support. The good news is that the glue is pretty smooth throughout. I'm glad you raised the issue of voids, gaps in the glue. I do have some of those. I was mistakenly thinking that by going wet on wet that the resin would fill those voids. Sounds like the best insurance is fill them now and not count on that. That will be a relatively easy task to complete.

Now, it's about getting the time, going to the deer lease this weekend. I've never been on a deer lease till this year. I was always one of those guys that loved hunting season cause that was less fishing pressure during a prime time of year. Oh well, I'm loving this deer lease thing anyway and wondering now why it has taken me 35 years to ever get on a lease.

So, updates may be a a week or so away.

Re: Mikem59 FS18 Build

Posted: Sat Nov 09, 2013 9:53 pm

by Mikem59

Very little progress over the past couple of weeks. Traveling for work and opening weekend for deer season have slowed me down. More travel next week as well.

My biggest hang up right now is whether or not I can move onto taping the seams. I've done some touch up to fill voids and sanded high spots as well. I've still got some voids that I'm concerned with. The are small, less than a 1/16" deep. Will the resin fill those voids or will they just create an air bubble. My gut tells me to keep at filling these till I get a good smooth surface.

The first pic is a slight void along the chine.

This pic is on one of the panel joints.

I'm getting anxious to move to the next step, but need that shove in the right direction.

Mike

Re: Mikem59 FS18 Build

Posted: Sun Nov 10, 2013 6:34 am

by Walkers Run

I would fill those voids with thickened epoxy, not to stiff. Then glass over it wet on wet.

Re: Mikem59 FS18 Build

Posted: Sun Nov 10, 2013 6:37 am

by Cracker Larry

Yes, you need to fill those with thickened epoxy, resin alone won't do it and you will have air bubbles.

Re: Mikem59 FS18 Build

Posted: Sun Nov 10, 2013 8:34 am

by AtTheBrink

Do what Walker and Larry said! Fixing air pockets sucks, get the surface as smooth and fair as you can now. It make taping and glassing easier and fairing after you glass with be easier and faster. One thing I learned from Cracker Larry, work clean! Clean up drips and runs as they happen, don't use more epoxy than you need, same goes for glue and fairing compounds. It's a lot easier to take fairing compound off with squeegee when it's still wet than to sand it fair after it cures.

Passing on the Cracker Lesson

Re: Mikem59 FS18 Build

Posted: Sun Nov 10, 2013 9:18 am

by Cracker Larry

Lessons learned the hard way

Re: Mikem59 FS18 Build

Posted: Mon Nov 11, 2013 10:25 am

by pee wee

It's the same practice when doing drywall work- watch the pros do it and they leave a surface that looks like it's ready to paint once it dries. Of course epoxy is a lot harder to sand, but it's the same concept.

Re: Mikem59 FS18 Build

Posted: Mon Nov 11, 2013 4:35 pm

by Mikem59

I'll keep listening to my gut and you guys. That's what the forum is all about, helping rookies like me ultimately get it right and avoid as many mistakes as we can.

With the advice I went back over all the little voids and filled. I'll check the results of that effort this evening. I'll just say There is a lot to be said for controlling the amount of epoxy used, the thickness of the glue, runs, drips, etc. it's a learning process for sure.

I'm not so quickly learning

that each step may require some recipe tweaking to get the desired results.

Thanks and more to come!

Mike

Re: Mikem59 FS18 Build

Posted: Tue Nov 26, 2013 2:53 pm

by Mikem59

Finally getting back to doing some work on the boat. Did a little more filling of voids and sanding. Now, I believe I'm finally ready to begin glassing the keel, transom, and bow seams. However, I do have a question.

For the keel, do I run a continuous strip of fiberglass all the way down to the top of the bow, or do I do the bow section separately? I've reviewed some of the other builds and it's difficult to see just how this is done.

Re: Mikem59 FS18 Build

Posted: Tue Nov 26, 2013 5:20 pm

by Cracker Larry

Yes, at least that's how I did it. Down the keel requires 2 overlapping pieces of tape and I ran them from the transom to the tip of the bow. The tape will conform to the bend, if it wants to pucker cut a slit in it so it lays flat. Same with laying the cloth, run it full length and cut slits where it puckers.

Re: Mikem59 FS18 Build

Posted: Tue Nov 26, 2013 5:58 pm

by Mikem59

Thanks Cracker Larry. Once again some reassurance on how to move forward. Now, just need some warmer weather.

Mike

Re: Mikem59 FS18 Build

Posted: Tue Nov 26, 2013 6:26 pm

by Cracker Larry

Me too!!

Re: Mikem59 FS18 Build

Posted: Thu Nov 28, 2013 11:41 pm

by justin_dwyer

I just learnt a heap from this post about doing my boat, I am epoxy gluing the seams and then will tape.

Great tips.

Your boat is coming along great Mike, watching with interest.

Cheers

Justin

Re: Mikem59 FS18 Build

Posted: Wed Dec 04, 2013 9:30 pm

by Mikem59

Justin - thanks. At the rate I'm going, a guy starting his build now will pass me up. This work thing sure makes it difficult to get some quality chunks of time in, but it does pay the bills and for the build.

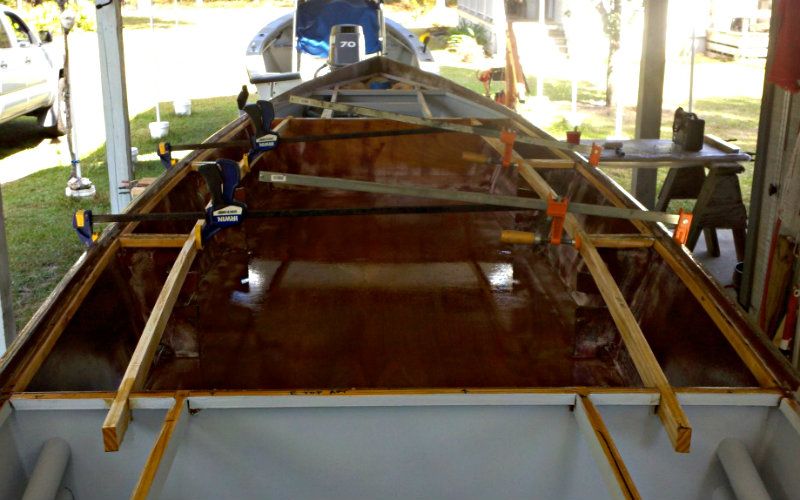

I've managed to get quite satisfied with the touch up work and sanding to start prepping for taping the seams. I've measured out the required glass for the keel (2 strips to be overlapped), the chines and the transom. And, I've marked the hull where the edges of the glass should line up to. And, I've set up a larger resin mixing table that is also easier to get to than where I was set up before.

I've got a small Stanley space heater, hoping that can warm up my work area enough to work since this weekend weather forecast is calling for some cold weather. I found out a couple of weeks ago that although the resin will still cure, albeit over a long time, the plungers to measure out my mix isn't the best way; that cold resin and hardener don't pump out very easily.

However, the colder weather may be good for these next steps as it will certainly give me plenty of time to lay it up without it kicking on me. At least I think that is a good thing.

Also, as for calculating the amount of resin, I've reviewed the forum and confirmed that it should be a 50:50 mix of resin to glass on a weight (ounces of resin to ounces of glass). Based on that for example, the keel will be approximately 2 strips of glass tape approximately 18' long and 6" wide. That's 9 sq. ft. or 1 sq. yd. per strip. At 12oz. per yard of glass, it will thus take 12 oz. of resin per strip. The chines going from the bow all the way to the top of the transom is roughly 21', so a little more resin than 12 oz. I guess I'm putting this out here for confirmation. I'll add in maybe a 10% fudge factor, then get everything pre measured and ready to mix so I can move from one strip to the next.

Lastly, here are just a few pics of the prep for the seams.

Re: Mikem59 FS18 Build

Posted: Thu Dec 05, 2013 8:08 am

by tcason

I warm up the epoxy to + - 70 to 80 degrees in the plastic bottle before mixing. It will pump and flow much better.

If you pour out the epoxy after mixing on the colder surface that should give you ample working time.

Your results may vary and maybe the experts will chime in.

FROM WEST SYSTEM

http://www.westsystem.com/ss/cold-temperature-bonding/

.

Warm resin and hardener before using. As mentioned, the warmer the resin and hardener, the lower the viscosity. Thinner resin and hardener will flow through pumps better, cling less to containers and mixing equipment, and mix more thoroughly. The initial chemical reaction will get off to a better start and result in more cross-linking even if the mixture cools after it is applied to a cooler surface. The thinner mixture will initially flow out smoother and wet-out porous surfaces better.

Warm the resin and hardener with heat lamps or keep it in a warm area until you are ready to use it. You can build a small portable hot box out of rigid sheets of foil-backed insulation, with a regular light bulb or an electric heating pad inside to maintain a temperature of 70°F–90°F. This method allows you to keep the warm resin and hardener close to your work and allows less time to cool off between dispensing and application.

Re: Mikem59 FS18 Build

Posted: Thu Dec 05, 2013 8:30 am

by Cracker Larry

Good looking prep work. Planning ahead makes it all go smoother. For the 6" tape I've learned that it needs about 1 ounce of epoxy per foot of tape. That usually works out perfect. After you mix it, pour it out immediately on the tape. If I'm going to lay a piece of tape 18' long, I mix 18 ounces of epoxy and pour it out evenly along the entire length of tape, then roll it in. Once it is out of the cup you will have plenty of working time even if it's hot.

If the epoxy is under 65 degrees it is very difficult to work with and it takes a lot more of it to wet out the cloth. The warmer it is, the easier it is to spread and you get better coverage.

Re: Mikem59 FS18 Build

Posted: Thu Dec 05, 2013 7:09 pm

by Mikem59

Tcason, thanks for the input. It's good to know that the warmer resin not only improves the pump ability, but improves the cross linking.

CL, Thanks as well. The ounce per foot of 6" cloth is an easy go by. I do have a question though, I was planning on laying down a thin coat of resin, then lay the cloth, then follow with the resin on top to wet it out, would I need to eliminate the initial coat? And, do you use the aluminum laminating roller or a cloth, tight nap roller to wet it out? I have both, and when I say tight nap, I found some 1/4" nap rollers at Lowes.

By the way, the cold front is moving through as I speak here. Calling for a low of 37 and only a high of 42 for Saturday.

Hope the heater works.

Re: Mikem59 FS18 Build

Posted: Thu Dec 05, 2013 8:08 pm

by justin_dwyer

Looking very organised Mike

I am interested in that last post too, prime the strip first or just lay the tape out, clamp it and pour the epoxy onto it and let the wood soak it from the cloth?

Good luck on the weekend Mike, keen to see how it goes, I'll be there probably next weekend

Cheers

Justin.

Re: Mikem59 FS18 Build

Posted: Thu Dec 05, 2013 9:41 pm

by Mikem59

Thanks Justin. I'm thinking since I've finally have a full weekend, I've got to find a way to make some progress regardless of the cold. I may take the suggestions to heat the resin.

Later,

Mike

Re: Mikem59 FS18 Build

Posted: Thu Dec 05, 2013 9:44 pm

by Cracker Larry

When it's on a mostly horizontal surface I usually just lay out the tape dry, then pour and roll the epoxy over it. Where it goes on vertical surfaces I put a little epoxy on the wood first, let it tack up a bit, then put on the tape and finish wetting it out. I use high density 4" foam rollers, also from Lowes. Marked Whizz Door and Cabinet rollers

http://www.lowes.com/pd_119118-11591-94 ... Info=WHIZZ

Re: Mikem59 FS18 Build

Posted: Thu Dec 05, 2013 9:49 pm

by justin_dwyer

Sucks when you finally get some time away from work, family commitments, etc and the weather is no good

I am basically building mine outside, I have a roof, but no sides and at this time of the year the temps are fine (30 - 35C), but we get rain nearly everyday, and the tropical storms come in pretty quick so I get reluctant to do too many big jobs, like glassing the bottom with cloth will be interesting

...still haven't work out how I'll do that yet, other waight for 6 months til the dry season, which is too long for me.

Yeah, heat up the resin and get one or two of the gas outdoor heaters, we can hire them here in Australia for parties, etc. Not sure if you can there. They kick out some good heat, and you have a good enclosed are there that will trap it.

Good luck!!

Justin.

Re: Mikem59 FS18 Build

Posted: Sat Dec 21, 2013 11:21 am

by Mikem59

I finally got a break in the weather and my schedule earlier this past week and got the seams completed. Once again, a milestone accomplished. Up to this point, it's been a solo project, but got some help on the seams. Having an extra hand certainly makes things easier.

Here are some pics:

Layed out dry to verify the length, then cut a slit at the bow to aid in getting it to fold/lay. (Thanks CL)

A thin coat of resin before rolling out the cloth. This certainly helped keep the cloth in place when wetting it out. My help hadn't shown up yet either at this point.

Close up at the bow once I started laying the cloth. The slit sure helped.

No intermediate pics prior to getting to this point, I've already got some resin on my life proof screen for the phone.

Transom shot.

After the cure. I'm pleased, but the next two pics show some potential problems.

Some cloth along the joint that did not appear to wet out completely.

Same thing on the chine.

Regarding the "white" spots that did not appear to wet out, I've read through the forums and found that it may be possible to go over these with some more resin to wet out. I think that'll work, but I'm going to take a closer look today before I take any rash actions. Raining here today, so I'm going to start going through the scraps to see how much of the rub rails pieces I can rip.

Re: Mikem59 FS18 Build

Posted: Sat Dec 21, 2013 12:22 pm

by Mikem59

By the way, any suggestions on a minimum length for salvaging pieces for a rub rail that will be easy to work with? I'm looking at my scrap right now and don't think I'll 1) be able to have a piece much longer than 4 or 5 foot, 2) won't have near enough to assemble 3 layers 18'+ long. As much as I hate to admit it may need another sheet of marine ply. I'll need more anyway for my console.

Re: Mikem59 FS18 Build

Posted: Sat Dec 21, 2013 3:21 pm

by Shamrock Kid

Looks good Mike your still moving forward. I think you have the right idea of wetting out the edge's that didn't wet out to well. I cut my rub rail strips from an extra sheet of ply. The scraps can be used and probably is the most efficient use of the wood. But I took the easier route and ripped them out on the table saw. Just remember to stager the joints. I accomplished this by cutting some of them down to 4' sections. So I had 8' and 4' sections this way you don't end up with aligned seams and a weak spot in the rub rail. But your build is looking good. Seeing the pics reminds me of when I was there it feels like yesterday. Keep plugging away and updating us, I love watching these boats come together. I'm fixing to order a set of OD18 plans.

Re: Mikem59 FS18 Build

Posted: Sat Dec 21, 2013 3:29 pm

by Mikem59

John,

Thanks for the encouragement and suggestions, I just finished wetting out those edges and I think it's going to work.

As for the rub rail, totally agree on the stagger for the joints. I'm killing time now cutting some scrap to make fairing boards for now.

Later,

Mike

Re: Mikem59 FS18 Build

Posted: Sun Dec 22, 2013 12:56 pm

by Mikem59

Not much work done yesterday, basically, attempted to wet out the "white spots", cut some scrap to make some fairing boards, and knocked off the excess cloth.

Just a couple of pics, one to show the Stanley Sureform planer, one heck of a useful tool.

Re: Mikem59 FS18 Build

Posted: Mon Dec 23, 2013 7:38 pm

by justin_dwyer

Looking great Mike.

Those planers are definitely a handy bit of gear, I have used mine so much that the blades have gone flat, time for some new ones.

Keep up the great progress.

Cheers

Justin

Re: Mikem59 FS18 Build

Posted: Mon Dec 23, 2013 8:02 pm

by peter-curacao

howbout a grinder with a 60 or 80 grit flapper disk?

Re: Mikem59 FS18 Build

Posted: Tue Dec 24, 2013 10:43 am

by Mikem59

peter-curacao wrote:howbout a grinder with a 60 or 80 grit flapper disk?

Ha, don't have one of those, but hey, This boat build has led to some new tools, and besides its Christmas

I'm sure that grinder could knock out that work in short order.

As for progress on the boat, I spent about 3 1/2 hours sanding the seams. While doing that the one "White spot" near the chine and on the hull panel joint blew out. I was afraid of this on this particular spot as I could never get it to wet out.

I put the Stanley Sureform planer to work as well as my RO sander to clean up this spot and reglass it. Just checked it out and it looks much better. I'll post pics later.

I'll be ready to glass the hull soon, but the weather is too cold right now to attempt. Probably won't get a shot at this till after New Years.

Regarding glassing the hull, the BOM for the kit states 13 yds of 50" cloth. I calculated that to amount to a total length of 28' of cloth. My intentions are to apply glass to cover the entire hull sides as well. But, 28' of cloth won't be enough. I should have known that since the plans don't call for doing it that way. Looks like I'll order some more cloth soon.

Merry Christmas to All You Boat Builders!

Re: Mikem59 FS18 Build

Posted: Tue Dec 24, 2013 11:12 am

by Mikem59

Pics of the latest fix.

Sanded to remove the glass and resin along and below the chine and along the full width of the joint

Here's the after pic. It's not pretty. In an effort to make sure I had wetted it out real good and to not mess up the weave, I used a piece of plastic over top while wetting out.

Just need to clean this up, do some touch up sanding and get ready for that next big step!

Re: Mikem59 FS18 Build

Posted: Tue Dec 24, 2013 9:38 pm

by Shamrock Kid

Mikem59 wrote:Regarding glassing the hull, the BOM for the kit states 13 yds of 50" cloth. I calculated that to amount to a total length of 28' of cloth. My intentions are to apply glass to cover the entire hull sides as well. But, 28' of cloth won't be enough. I should have known that since the plans don't call for doing it that way. Looks like I'll order some more cloth soon.

Merry Christmas to All You Boat Builders!

Mike, yup the BOM is correct because by design the cloth only needs to go past the chine 6". But the way your going to do it is in my option correct too. I'm covering all exposed wood with cloth. The sole has already been covered in 10oz, the deck will also get covered but I think I'm going to go 12oz biaxial on it.

You build is looking good, Merry Chrstmas to you too!

Re: Mikem59 FS18 Build

Posted: Sun Jan 05, 2014 9:06 pm

by Mikem59

Well placed an order for 10 yds of 12 oz biax cloth so I can do the entire hull. Waiting won't be so bad, cold weather has kept me from doing much anyway, and it's going to be cold most of the week here.

And, while I'm on my way to the deer lease next weekend, I'll make a stop at Houston Hardwoods to pick up a sheet of 6mm 1088. I'll use that to rip the rub rails and also for my console.

Re: Mikem59 FS18 Build

Posted: Sun Jan 19, 2014 11:02 pm

by Mikem59

Finally took the plunge and got the hull glassed. Feeling good about the accomplishment, but always worry with anticipation to see the outcome. That was alot of work. Reading about all the other boat builds and the time it takes doesn't sink in until you're doing it for your first time.

Did the glassing over three days, day one, with some help, rolled out the glass, and cut to length. Also, cut the rub rail strips since I had help. Day two, finished trimming the fiberglass on the hull.

Day three, glassed the hull. This step alone, with help at about the half way point still took six hours. I had no idea how difficult it would be to wet out the fiberglass. Not sure if that was a function of temperature or not. Or, that's just the way it it. When I started, it was about 70 deg. By the time we finished, it was 53 deg outside. I did have a space heater going in the shop. Also, I used the medium speed hardener. Didn't have any issues with it kicking on me too quick. But, it didn't seem to take long to tack up.

And, wetting out the keel section where there was a 10" overlap on each side sure was difficult. Just voiceing all the fun I had in case I may have missed a few tips and tricks along the way.

Nonetheless, I'm quite happy to have completed this step, but I'm going to have alot of sanding, I'm guessing I went pretty heavy on the resin. I haven't tallied up how much I used just yet.

Here are some pics:

Re: Mikem59 FS18 Build

Posted: Sun Jan 19, 2014 11:34 pm

by justin_dwyer

Great job Mike

I bet it feels good to have that out the way, even if there is a bit of sanding to do.

Just waiting for the weather to ease here so I can glass mine. Just had a monsoon, so it has been raining for about 2 weeks here, everything has grown mold....so I am hoping my wood hasn't sucked up too much

Weather should ease here next week hopefully.

Cheers

Justin.

Re: Mikem59 FS18 Build

Posted: Mon Jan 20, 2014 8:10 am

by Mikem59

Justin,

Thanks! Wow, I feel for ya, two weeks worth of rain. I live on the TX Gulf Coast and we've had our bouts with extended rainfall. I can't recall two weeks worth in quite awhile. Eventhough I have a an enclosed storage building to work in, it isn't climate controlled, so I am still at the mercy of the temperatures and humidity. I'm just hoping my space heater kept things warm enough overnight for a good cure of the resin.

Sure hope that rain doesn't mess you up for much longer. Hang in there.

Re: Mikem59 FS18 Build

Posted: Mon Jan 20, 2014 8:46 am

by Cracker Larry

The glass looks great, Mike. It is much harder to wet out the cloth in cool temps and it takes more epoxy, but that looks excellent

Re: Mikem59 FS18 Build

Posted: Mon Jan 20, 2014 10:41 am

by Mikem59

Thanks CL. I suspected the cool temps were part of the culprit. I guess there's a bance between that and having time to wet out in warmer temps. This proves out that having help is key.

Re: Mikem59 FS18 Build

Posted: Tue Jan 21, 2014 9:52 pm

by Mikem59

Had a chance this evening to inspect the results of my hull glassing effort, and well, overall I am pleased with the outcome, epecially in light of this being a first time build. Here's what I observed, a sizable bubble about 2 inches in length and about 1/4 to 1/2 inches wide, dead center on the keel about 3 or 4 ft from the bow. Other than that, I found just a handful of other bubbles that were more than a 1/2 inch in length. And, then there are a number of bubbles no bigger than a pinhead. I found no soft or mushy spots anywhere. And, the chines, which I was most concerned with, looked real good with no unwetted resin or bubbles to speak of. Some of the bubbles I'm finding are predominantly along the the edges where the cloth overlapped the edge of the joint tape, particularly on the bottom where I'm guessing resin wanted to do its natural thing - follow gravity.

I'm going to consider the resin injection with the hypodermic needle before I take any drastic steps to start grinding away anything. As for the pinhead sized bubbles, do they have to be addressed?

I am glad I completed this step when I did because I would have surely lost another weekend due to polar vortex 2. Now, I've got the "repair" work to do, then lots of sanding.

My last comment, glad I completed this step, it was a huge learning experience, and one that I won't have hesitation to do the next time.

Re: Mikem59 FS18 Build

Posted: Tue Jan 21, 2014 9:59 pm

by justin_dwyer

Sounds like you've done really well Mike

Could you post some pics of the problem areas, as I haven't glassed mine yet (and I am a first time builder), I'd be keen to see what to look out for.

Great job again.

Cheers

Justin.

Re: Mikem59 FS18 Build

Posted: Tue Jan 21, 2014 10:09 pm

by Mikem59

Justin,

Yes, I meant to say I would post some pics. Just gotta get them uploaded to the gallery and then included in a follow up post. I'm hoping the pics will reveal the bubbles, glare and well, it's an iPhone, will,limit the quality. It'll probably be tomorrow before I get them posted.

Mike

Re: Mikem59 FS18 Build

Posted: Tue Jan 21, 2014 10:14 pm

by justin_dwyer

No worries, thanks Mike

Re: Mikem59 FS18 Build

Posted: Wed Jan 22, 2014 8:15 am

by wegcagle